Magnetron sputtering coating cathode structure

A technology of magnetron sputtering coating and cathode structure, which is applied in the direction of sputtering coating, vacuum evaporation coating, ion implantation coating, etc., can solve the problems of magnetic field attenuation, achieve stable magnetic field strength, solve quality degradation, and coating process stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

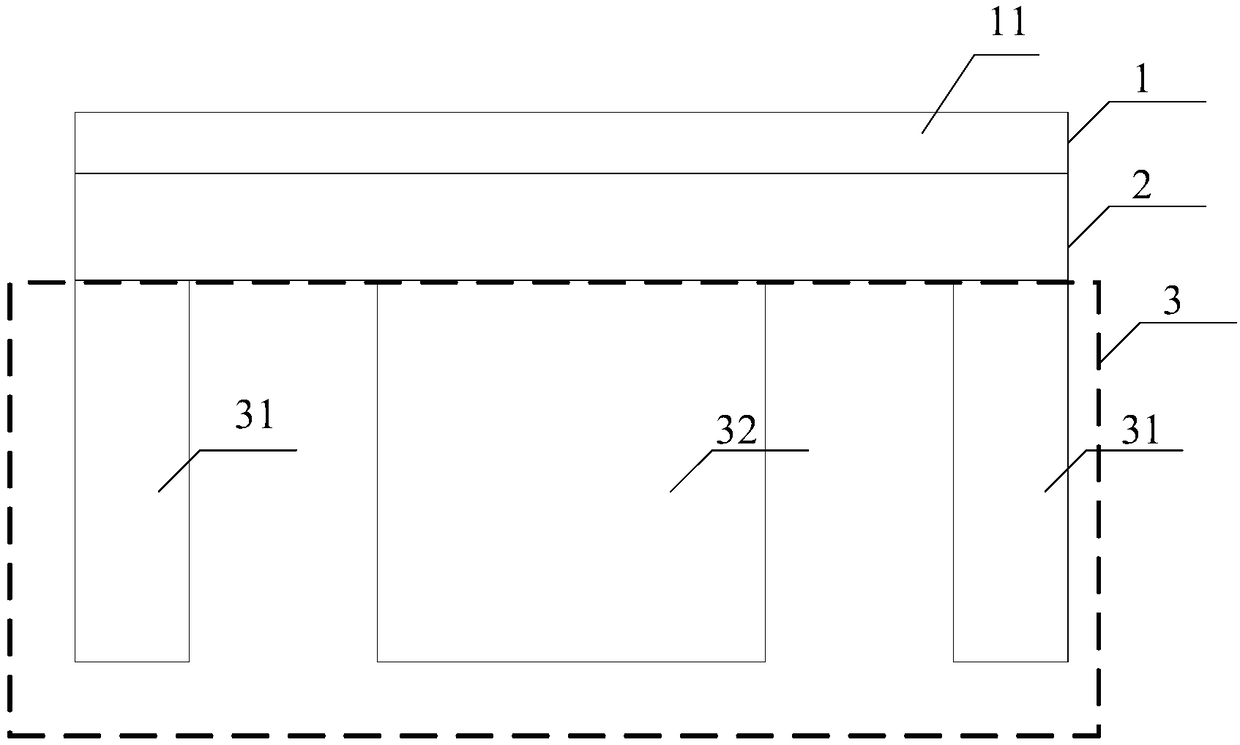

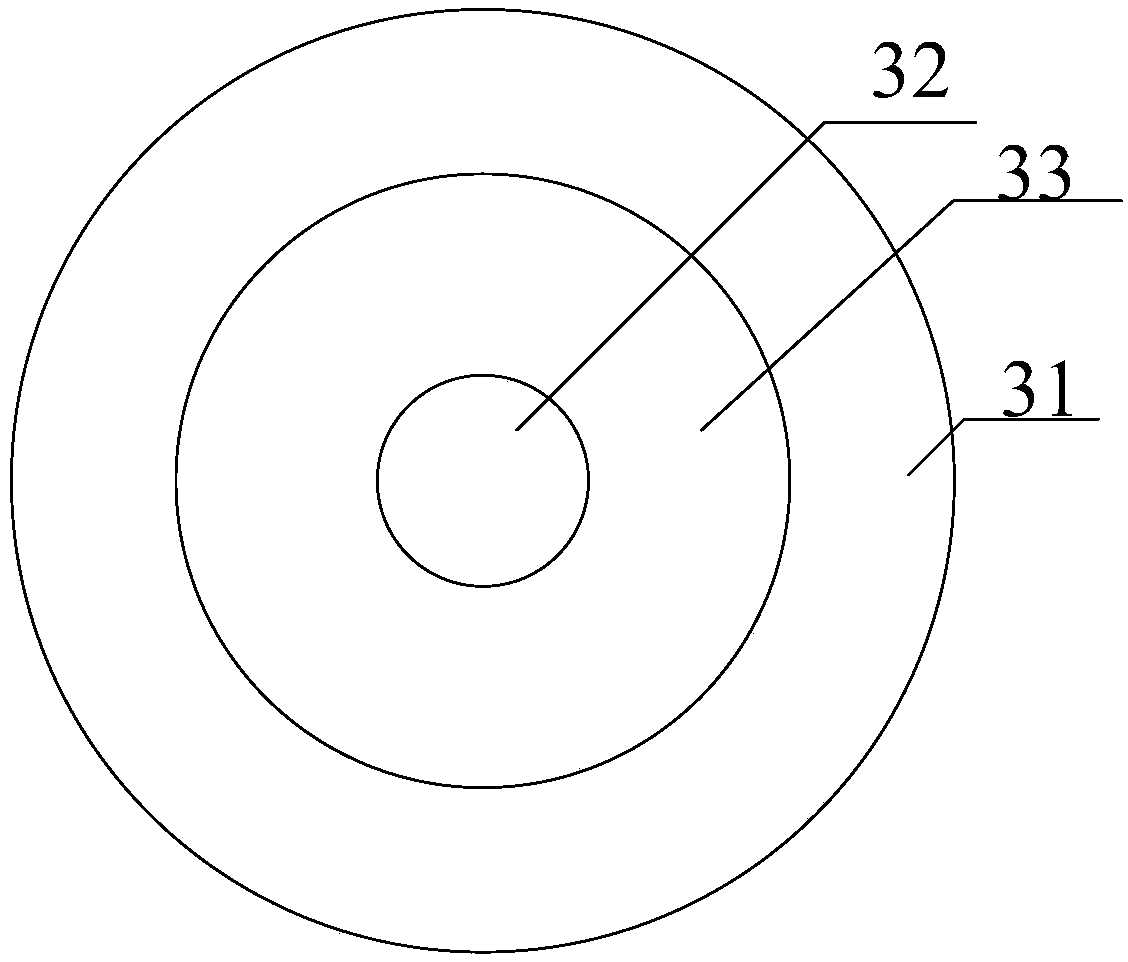

[0086] Specifically, the diameter of the back plate 2 is 91.6 mm, and the thickness is 6.5 mm. The first iron core in the first magnetic field generating structure 31 is a ring structure with an inner diameter of 71.6 mm, an outer diameter of 91.6 mm, and a height of 25mm, the diameter of the wire in the first excitation coil is 1mm, and the conductivity is 6×10 7 S / m, the number of turns is 3500 turns, the second iron core in the second magnetic field generating structure 32 is a cylindrical structure, its height is 25mm, and its diameter is 27mm. The diameter of the wire in the second exciting coil is 1mm, and its conductivity is 6. ×107S / m, the number of turns is 3500 turns, and the planar figure of the target structure 1 is a circle with a diameter of 91.6mm.

[0087] Carrying out geometric modeling on the above-mentioned cathode structure, defining the physical properties of air, setting the first target 11 as a titanium target, and setting the thickness of the first targ...

Embodiment 2

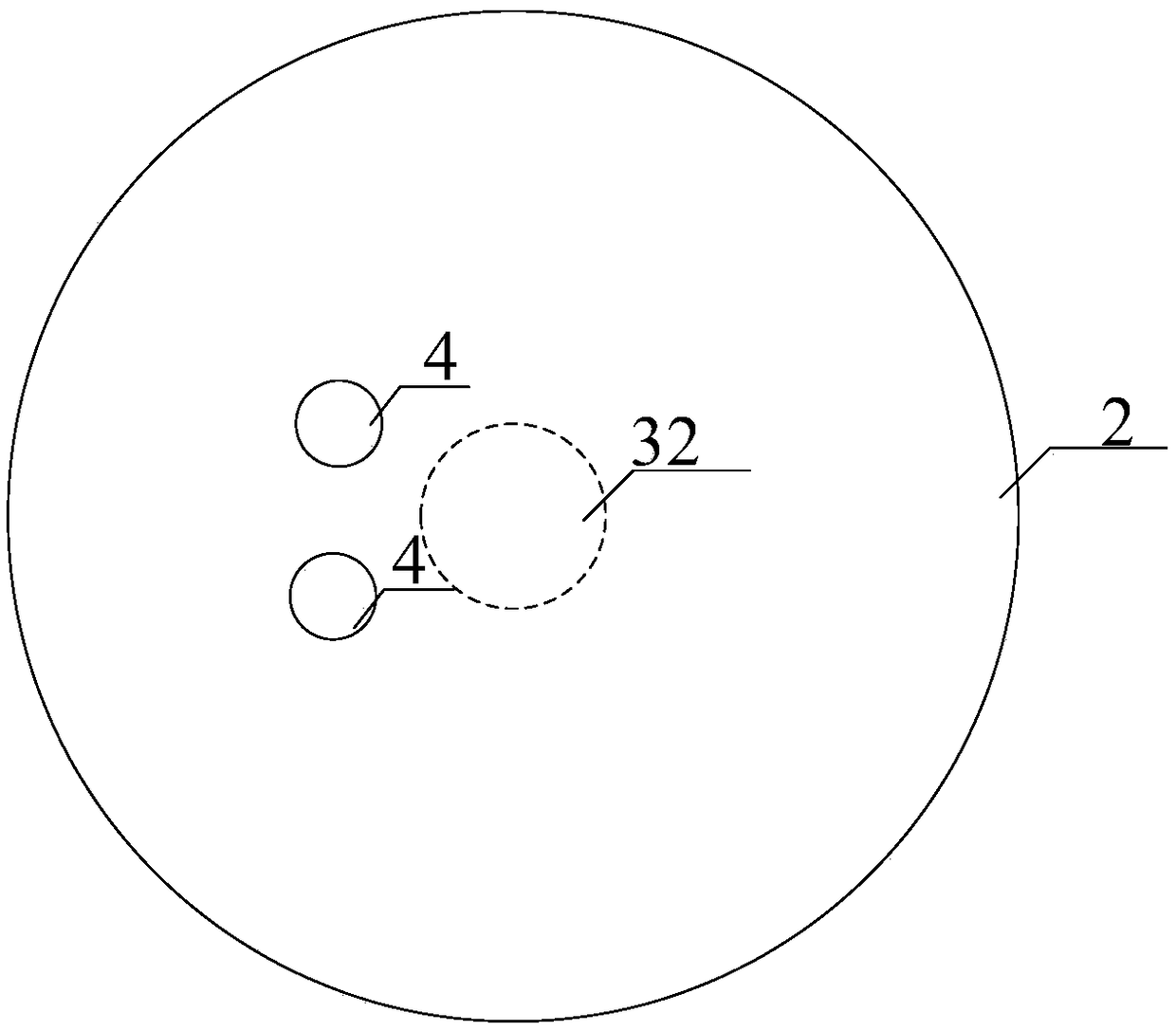

[0090] In the embodiment of the present invention, the target structure 1 only includes the first target 11, the plan view of the target structure 1 and the back plate 2 is circular, and the back plate 2 is Copper back plate, specifically, the diameter of the back plate 2 is 91.6 mm, the thickness is 6.5 mm, the inner diameter of the first iron core in the first magnetic field generating structure 31 is 71.6 mm, the outer diameter is 91.6 mm, and the height is 25mm, the diameter of the wire in the first excitation coil is 1mm, and the conductivity is 6×10 7 S / m, the number of turns is 3500 turns, the height of the second iron core in the second magnetic field generating structure 32 is 25mm, the diameter is 27mm, the diameter of the wire in the second excitation coil is 1mm, and the conductivity is 6×10 7 S / m, the number of turns is 3500 turns, and the plane pattern of the target structure 1 is a circle with a diameter of 91.6 mm.

[0091] Specifically, COMSOL Multiphysics so...

Embodiment 3

[0097] In the embodiment of the present invention, the target structure 1 includes two targets, the first target 11 and the second target 12, that is, the target structure 1 is a spliced target structure, and the target structure 1 and the The shape 2 of the backing plate is circular, and the backing plate 2 is a copper backing plate. Specifically, the shape of the second target material 12 is a disc shape, and several The second target 12, the diameter of the back plate 2 is 91.6 mm, the thickness is 6.5 mm, the inner diameter of the first iron core in the first magnetic field generating structure 31 is 71.6 mm, the outer diameter is 91.6 mm, and the height is 25 mm , the diameter of the wire in the first excitation coil is 1mm, and the conductivity is 6×10 7 S / m, the number of turns is 3500 turns, the height of the second iron core in the second magnetic field generating structure 32 is 25mm, the diameter is 27mm, the diameter of the wire in the second exciting coil is 1mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com