Hole-sealing device and method for flexible self-expanding gas extraction borehole

A technology of gas extraction and hole sealing device, which is applied in gas discharge, safety device, mining equipment and other directions, can solve the problems of strong randomness, difficult to mix accurately and fully, and cannot be mixed, etc., and achieves wide practicability and structure. Simple, lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

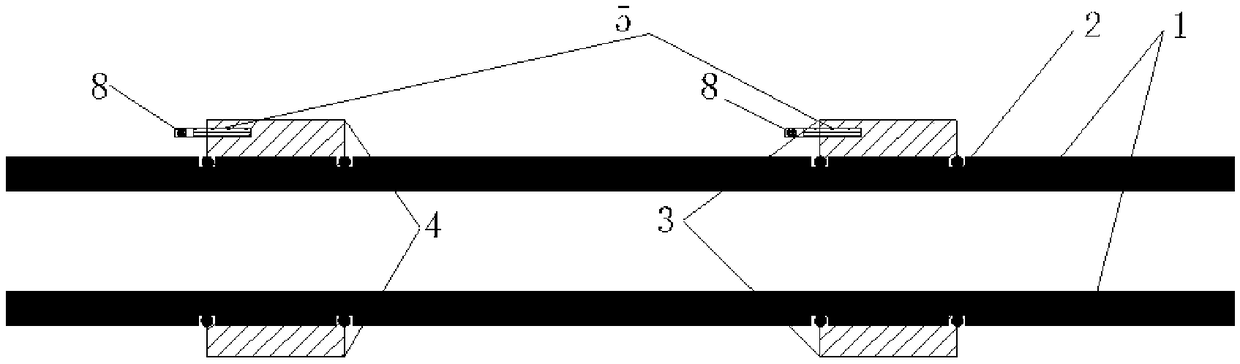

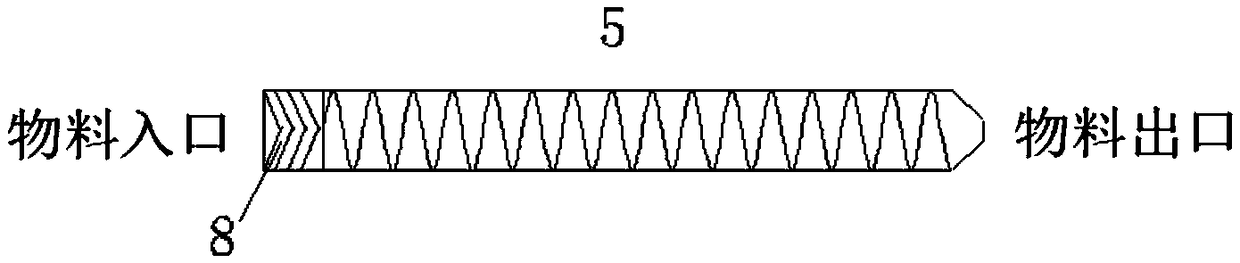

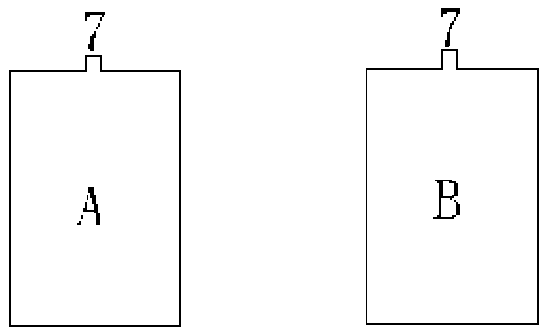

[0025] Such as figure 1 As shown, the flexible self-expanding gas drainage drilling and sealing device of the present invention includes a gas drainage pipe 1, a flexible plug and a material storage device, and the plug includes a flexible plug arranged on the gas drainage pipe 1 Head I3 and flexible plug II4, the material of the flexible plug I3 and flexible plug II4 is cylindrical high-strength non-woven fabric, the openings at both ends of the non-woven fabric are slightly larger than the outer diameter of the gas drainage pipe 1, and are formed by The clasp is bound and fixed in the fixed groove 2 of the gas drainage pipe 1, and the diameter of the middle part after the expansion agent AB is reacted and propped up should be more than 50% of the diameter of the drainage borehole; the flexible plug Ⅰ3 and the flexible plug Ⅱ4 are respectively p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com