Shield prefabricated segment

A technology of shield prefabricated segments and shield prefabricated tubes is applied in shaft linings, tunnel linings, underground chambers, etc., which can solve the problems of difficult cutting of steel bars, property damage, dangerous tunnel traffic safety, etc., and reduce the labor intensity of workers. , the effect of saving time and cost, reducing transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

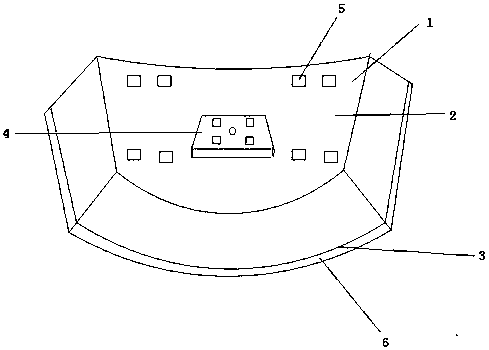

[0020] Example: such as figure 1 As shown, a shield prefabricated segment, the shield prefabricated segment main body 1 is made of concrete and is arched as a whole, including an inner surface 2 and an outer surface 3, and the inner surface 2 is provided with a boss 4 for The reinforcement in the concrete for pouring the shield prefabricated segment adopts glass fiber reinforcement, and also includes a thermoplastic interlayer 6. The thermoplastic interlayer 6 is arranged on the outer surface 3. The softening temperature of the thermoplastic interlayer 6 exceeds 110°C, preferably at 140 to 100°C. Materials made between 170°C. The thermoplastic barrier 6 should advantageously have at least a small degree of elasticity to be able to overcome stresses caused, for example, by temperature-induced differences in expansion between the thermoplastic barrier 6 and the shield prefabricated segments, without the thermoplastic barrier 6 being Damaged or torn and the sealing function of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com