Wet shotcreting machine

A technology of concrete and wet blasting machine, which is used in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problem that concrete mortar and compressed air cannot be mixed in proportion, can not be well adapted to complex terrain conditions, poor construction quality, etc. problems, to achieve the effect of improving pouring quality, avoiding oxidation and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

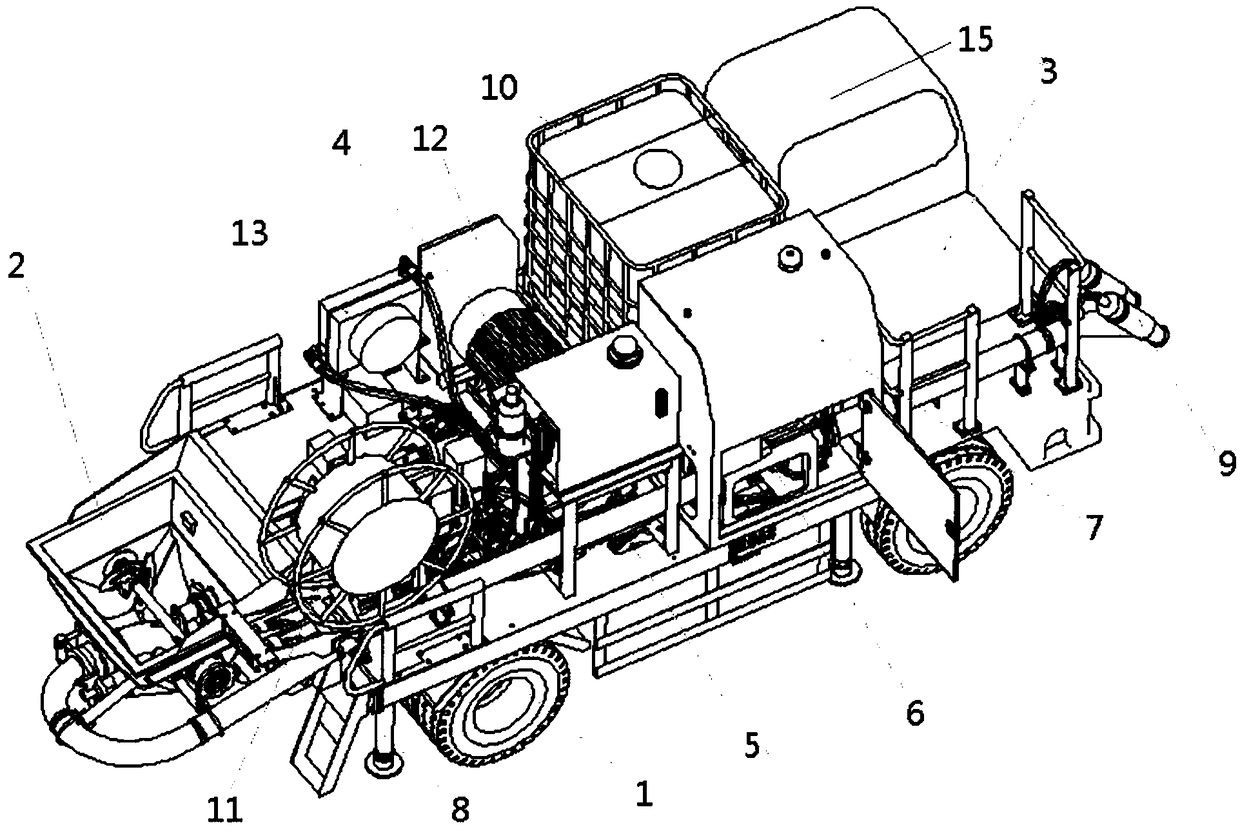

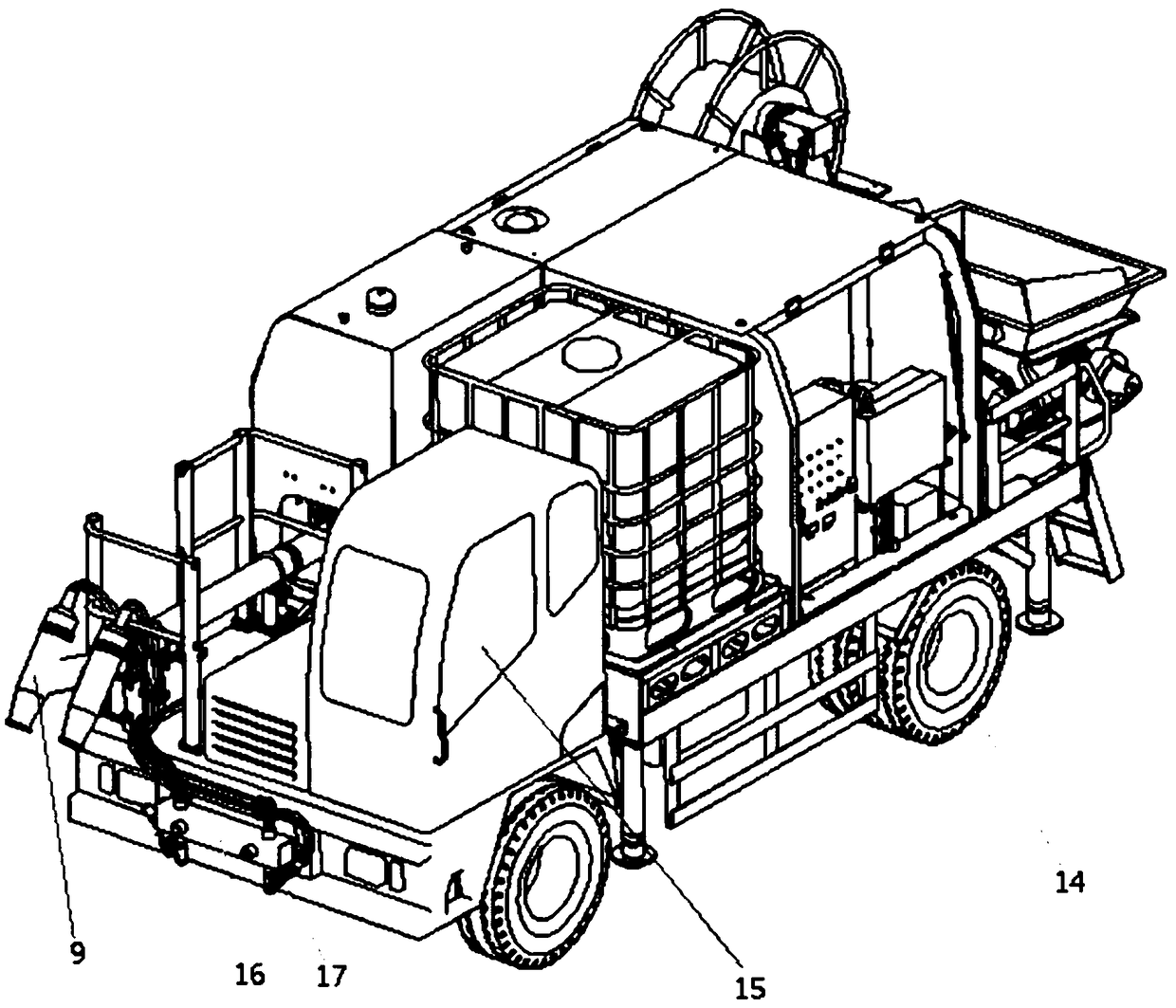

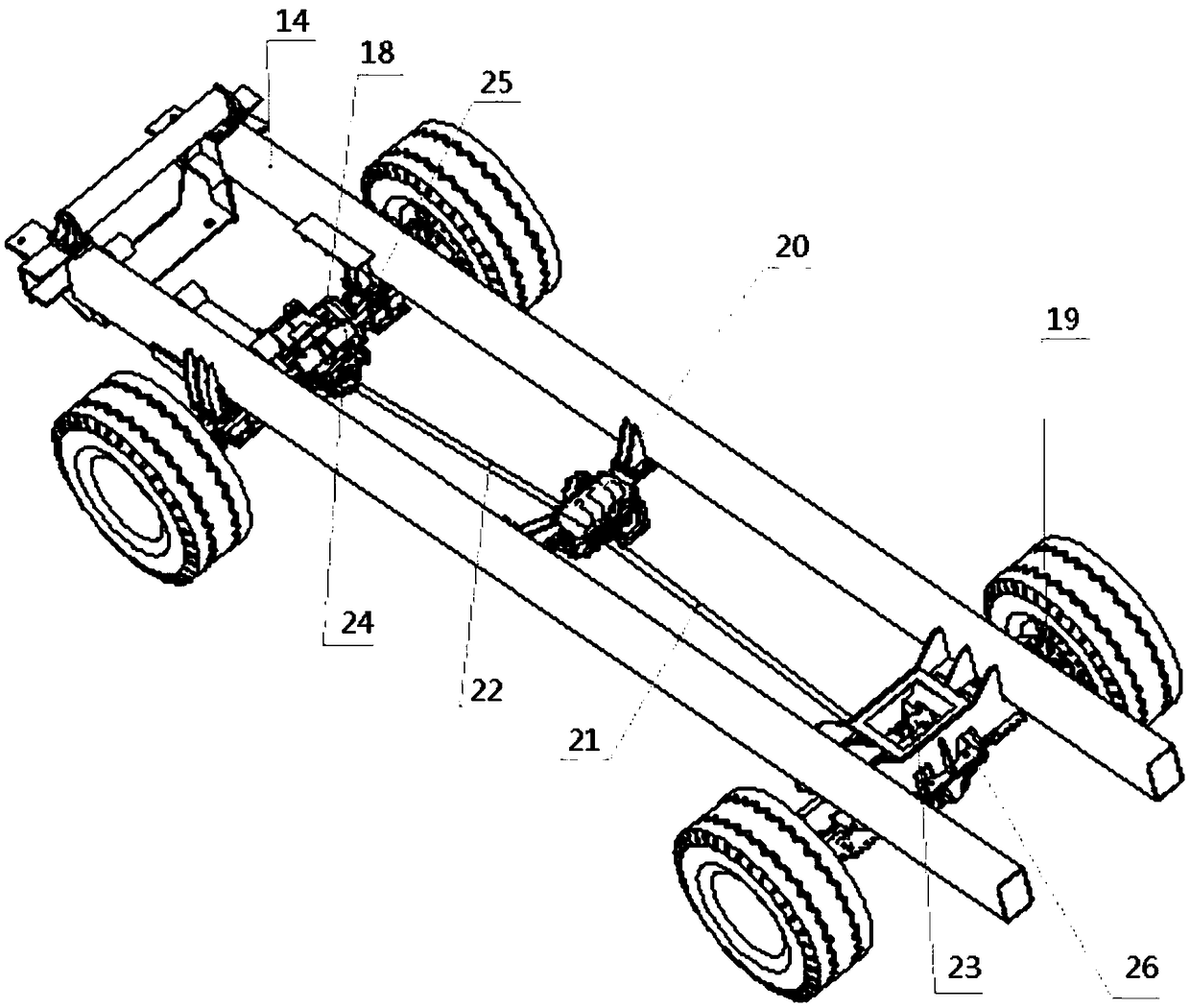

[0038] Such as Figure 1~2 Shown, a kind of concrete wet spraying machine of the present invention comprises mobile chassis 1, and mobile chassis 1 comprises vehicle frame and is arranged on four rollers below vehicle frame; Vehicle frame is provided with driver's cab 15, concrete pumping system, electric control system 12, fuel engine power system 3 and motor power system 4, a power switch is provided in the driver's cab 15, fuel engine power system 3 and motor power system 4 are connected with the power switch, and fuel engine power is selected through the power switch System 3 or motor power system 4 is used as a power source.

[0039]The whole machine contains two sets of independent power systems, which provide all the power for the whole machine. The two sets of power systems realize ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com