Drying equipment for metallic silicon microwave metallurgy

A drying equipment and metal silicon technology, applied in the field of materials, can solve the problems of damage to the connection between the nozzle and the tank wall, unfavorable metal silicon smelting, temporary coverage of the nozzle, etc., to improve the drying efficiency and the uniformity of product drying, and improve the service life. , the effect of improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

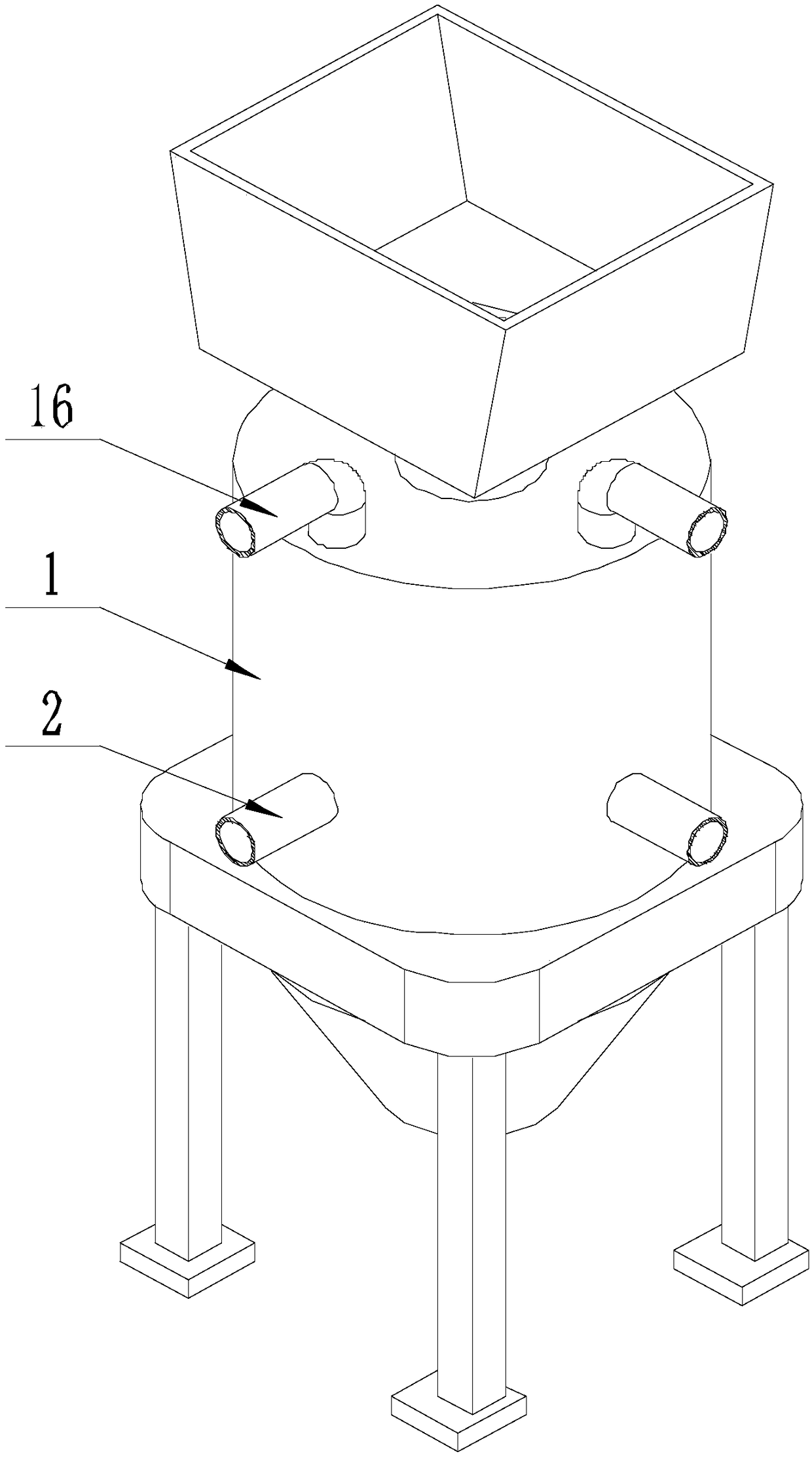

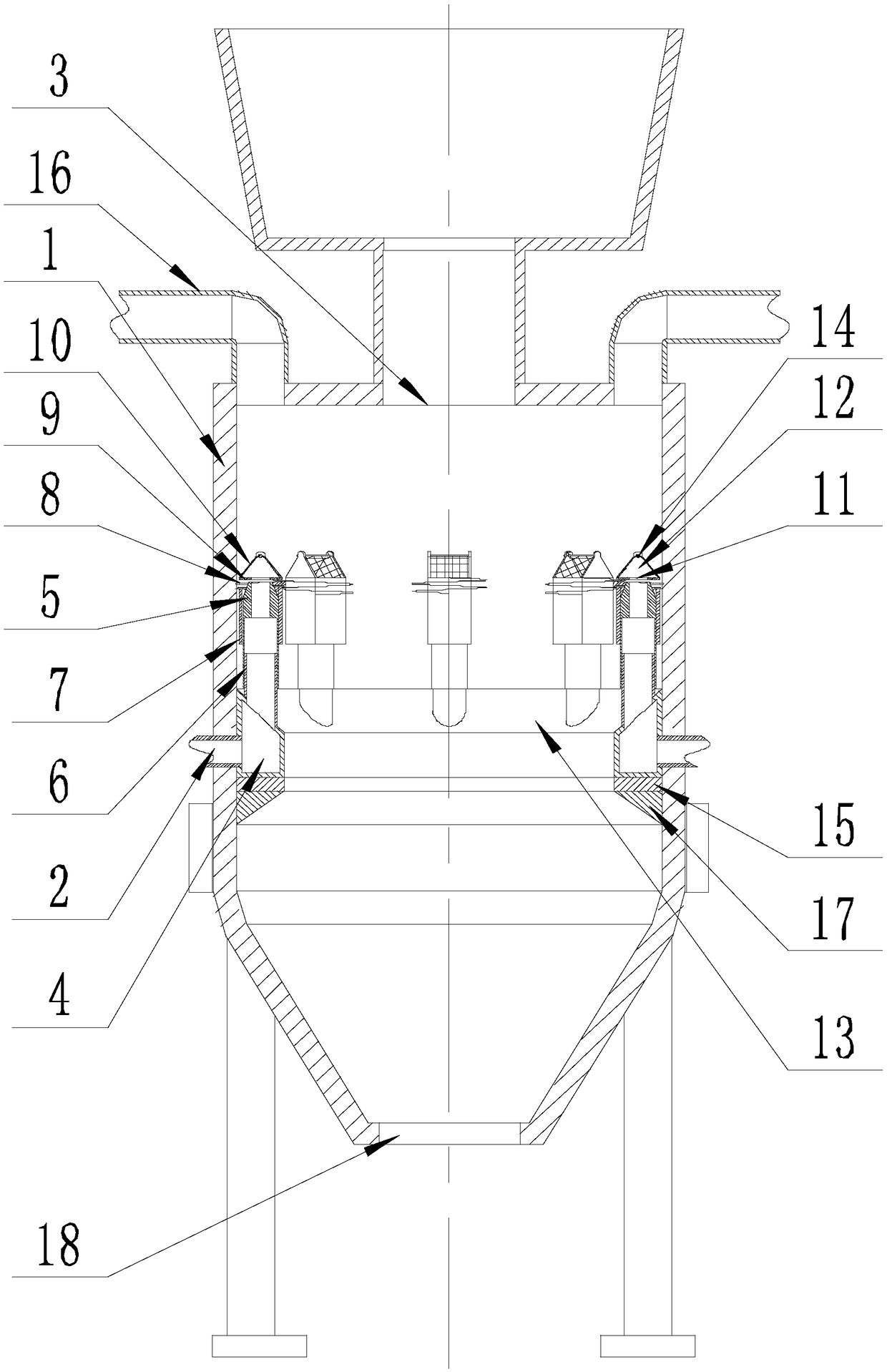

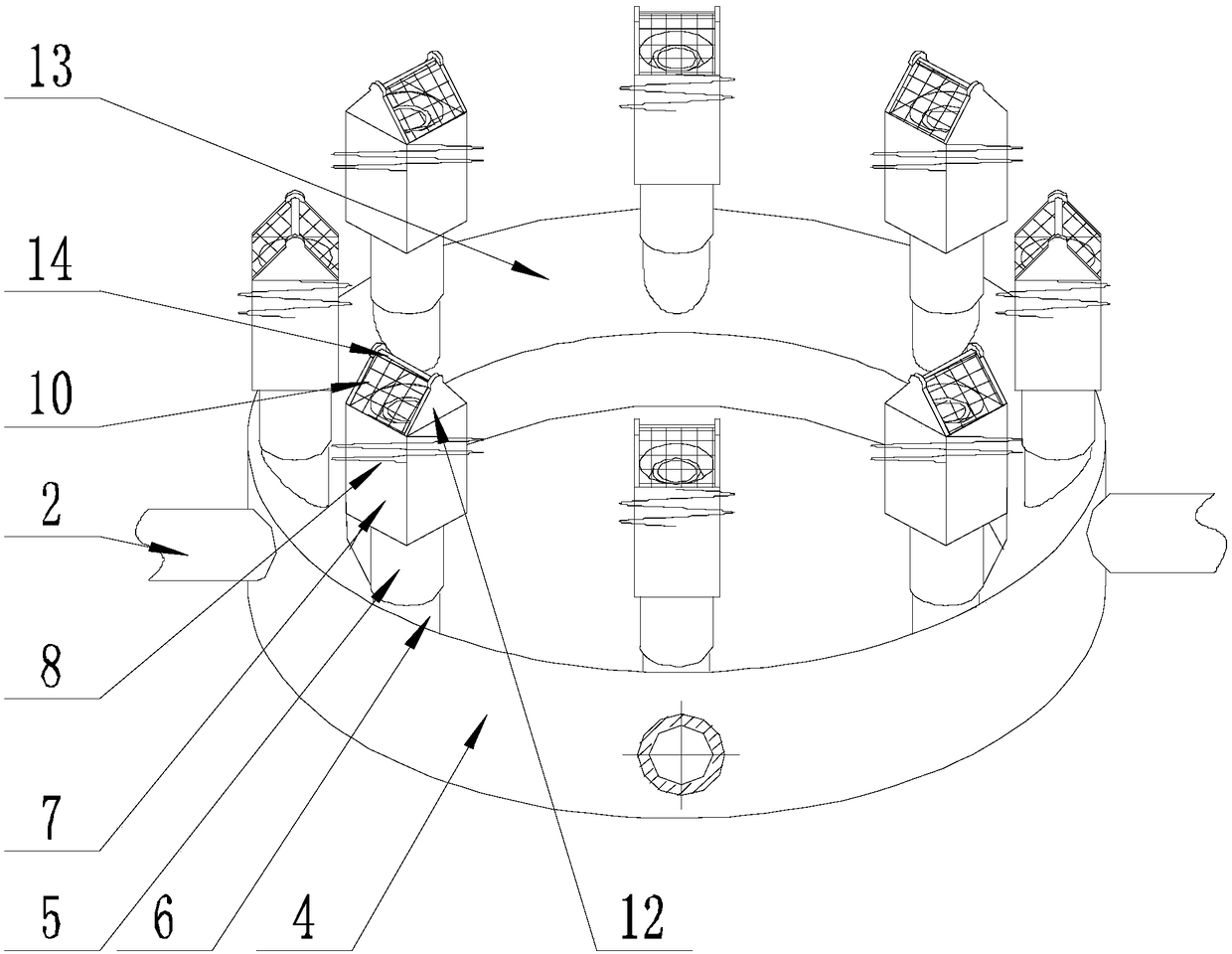

[0035] like Figure 1-Figure 8 As shown, the drying equipment for metal silicon microwave smelting of the present invention includes a drying tank 1 and a nozzle assembly connected in sequence, an air supply system and a nozzle 5. The nozzle 5 is located in the inner cavity of the drying tank 1, and the nozzle 5 is connected to the drying tank 1. The feed inlet 3 is opposite, and an anti-collision assembly is sleeved on the side wall of the nozzle 5 close to the nozzle. 10. One end of the connection cylinder 7 is sleeved on the nozzle 5, and the other end of the connection cylinder 7 is connected to the support plate 9 through a spring 8. The telescopic direction of the spring 8 is parallel to the axis of the nozzle 5. The support plate 9 Vertical to the axis of the nozzle 5, and the support plate 9 is provided with a ventilation hole 11 whose axis coincides with the axis of the nozzle 5. The support assembly includes two vertical plates 12 parallel to each other, and the bott...

Embodiment 2

[0038] Spring 8 is a helical cylinder compression spring.

Embodiment 3

[0040] This embodiment is based on Embodiment 1 to describe the air guiding system.

[0041] like Figure 1-Figure 8 As shown, in the drying equipment for metal silicon microwave smelting of the present invention, an air guide system is arranged between the air supply system and the nozzle 5, and the air guide system includes a hollow air guide ring 4 and an air guide pipe 2. In the drying tank 1 A support ring 15 is provided on the inner wall of the support ring 15, the axis of the support ring 15 coincides with the axis of the drying tank 1, the outer wall of the support ring 15 is connected with the inner wall of the drying tank 1, and the outer wall of the air guiding ring 4 is connected with the drying tank 1. The inner wall is in contact, the bottom of the air guide ring 4 is in contact with the top of the support ring 15, and the center line of the air guide ring 4 coincides with the center line of the drying tank 1, and several support cylinders 6 are arranged on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com