Method for preparing micro-nanostructure sample by using focused ion beam scanning electron microscope double beam system

A technology of focusing ion beam and scanning electron microscope, which is applied in the preparation of nanostructured samples and in the micro field, can solve the problems of difficulty in the growth of micro and nanostructures, and achieve the effect of improving real-time performance and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The concrete steps of preparation are:

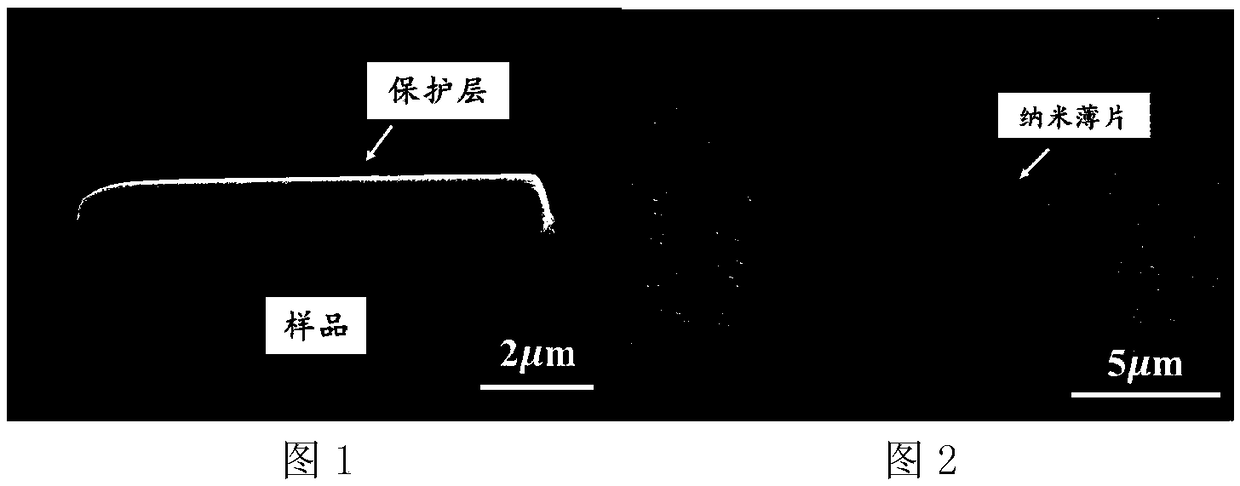

[0036] Step 1, prior to the surface deposition of the sample than the edge of the area to be measured 500nm wider, thick 0.5 μm containing organic protection layer; wherein, the deposition is to use electron beam deposition (or use ion beam deposition), the organic protection layer is Gold layer with organics. Then the sample is cut into micro-nano flakes with the same width as the protective layer.

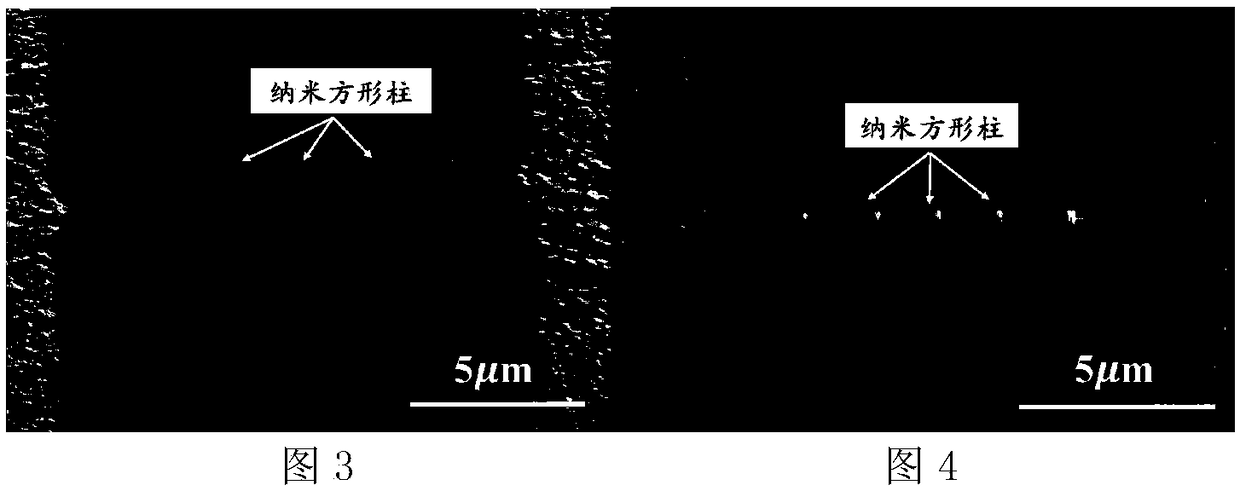

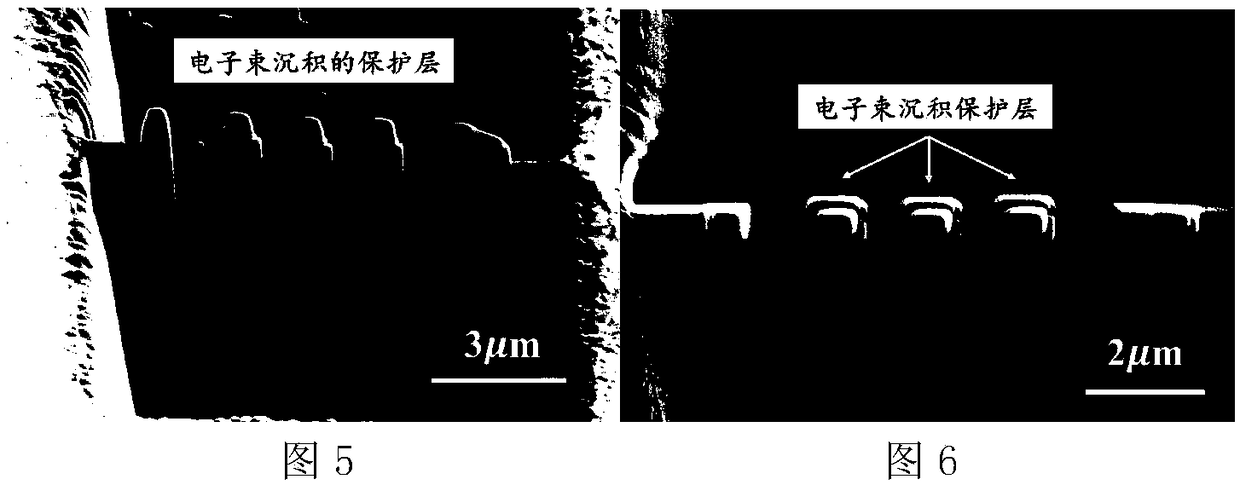

[0037] In step 2, the micro-nano sheet is first cut into columns whose cross-section is the shape to be measured; wherein, the shape to be measured is a rectangle which is one of the nano-polygons. After cleaning the amorphous layer on the surface of the columnar surface with an ion beam, use an electron beam to deposit a protective layer containing organic matter with a thickness of 50nm and an ion beam deposition thickness of 2μm; wherein, the protective layer containing organic matter is a gold layer containing organic matter ....

Embodiment 2

[0040] The concrete steps of preparation are:

[0041] Step 1, prior to the surface deposition of the sample than the edge of the area to be measured 600nm wider, thick 0.88 μm containing organic protective layer; wherein, the deposition is to use electron beam deposition (or use ion beam deposition), the protective layer containing organic matter is Gold layer with organics. Then the sample is cut into micro-nano flakes with the same width as the protective layer.

[0042] In step 2, the micro-nano sheet is first cut into columns whose cross-section is the shape to be measured; wherein, the shape to be measured is a rectangle which is one of the nano-polygons. After cleaning the amorphous layer on the surface of the columnar surface with an ion beam, use an electron beam to deposit a protective layer with a thickness of 163 nm and an ion beam with a thickness of 1.8 μm. layer.

[0043] Step 3, first use an ion beam to cut the columnar sample covered with an organic-contain...

Embodiment 3

[0045] The concrete steps of preparation are:

[0046] Step 1, prior to the surface deposition of the sample than the edge of the area to be measured 700nm wider, thick 1.25 μm containing organic protection layer; wherein, the deposition is to use electron beam deposition (or use ion beam deposition), the organic protection layer is Gold layer with organics. Then the sample is cut into micro-nano flakes with the same width as the protective layer.

[0047]In step 2, the micro-nano sheet is first cut into columns whose cross-section is the shape to be measured; wherein, the shape to be measured is a rectangle which is one of the nano-polygons. After cleaning the amorphous layer on the columnar surface with an ion beam, use an electron beam to deposit a protective layer containing organic matter with a thickness of 273nm and an ion beam deposition thickness of 1.5 μm; wherein, the protective layer containing organic matter is gold containing organic matter layer.

[0048] Ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com