A refractory shield cable for computer control

A fire-resistant computer and shielded cable technology, used in insulated cables, communication cables, cables, etc., can solve major accidents, signal distortion, equipment malfunction and other problems, achieve high safety, improve friction, and increase corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

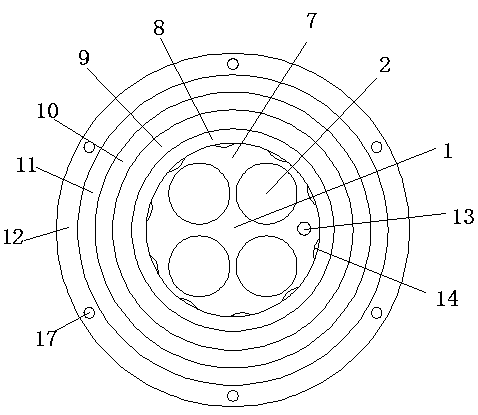

[0017] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

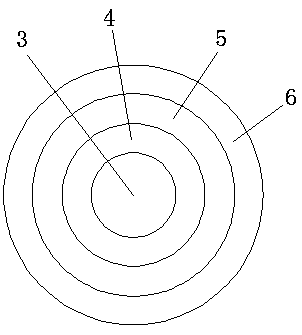

[0018] see Figure 1-Figure 3 , the present invention provides a technical solution:

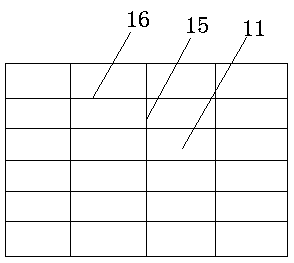

[0019] A fire-resistant shielded cable for computer control, including a cable assembly 1, the inner cavity of the cable assembly 1 is provided with a wire core 2, the center of the wire core 2 is provided with a metal conductor 3, and the outside of the metal conductor 3 is provided with a tape layer 4 , the outer side of the tape layer 4 is bonded with a phase-separated shielding layer 5 through an adhesive, which can shield multiple cables, so that the multiple wires working at the same time in the cable will not affect each other, ensuring accurate information transmission Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com