A Plasma Contactor with Annular Ionization Chamber

A plasma and ionization chamber technology, applied in the direction of plasma, electrical components, etc., can solve the problem of high cost of transplantation, and achieve the effect of improving the total discharge efficiency, realizing the discharge capacity, and optimizing the emission characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

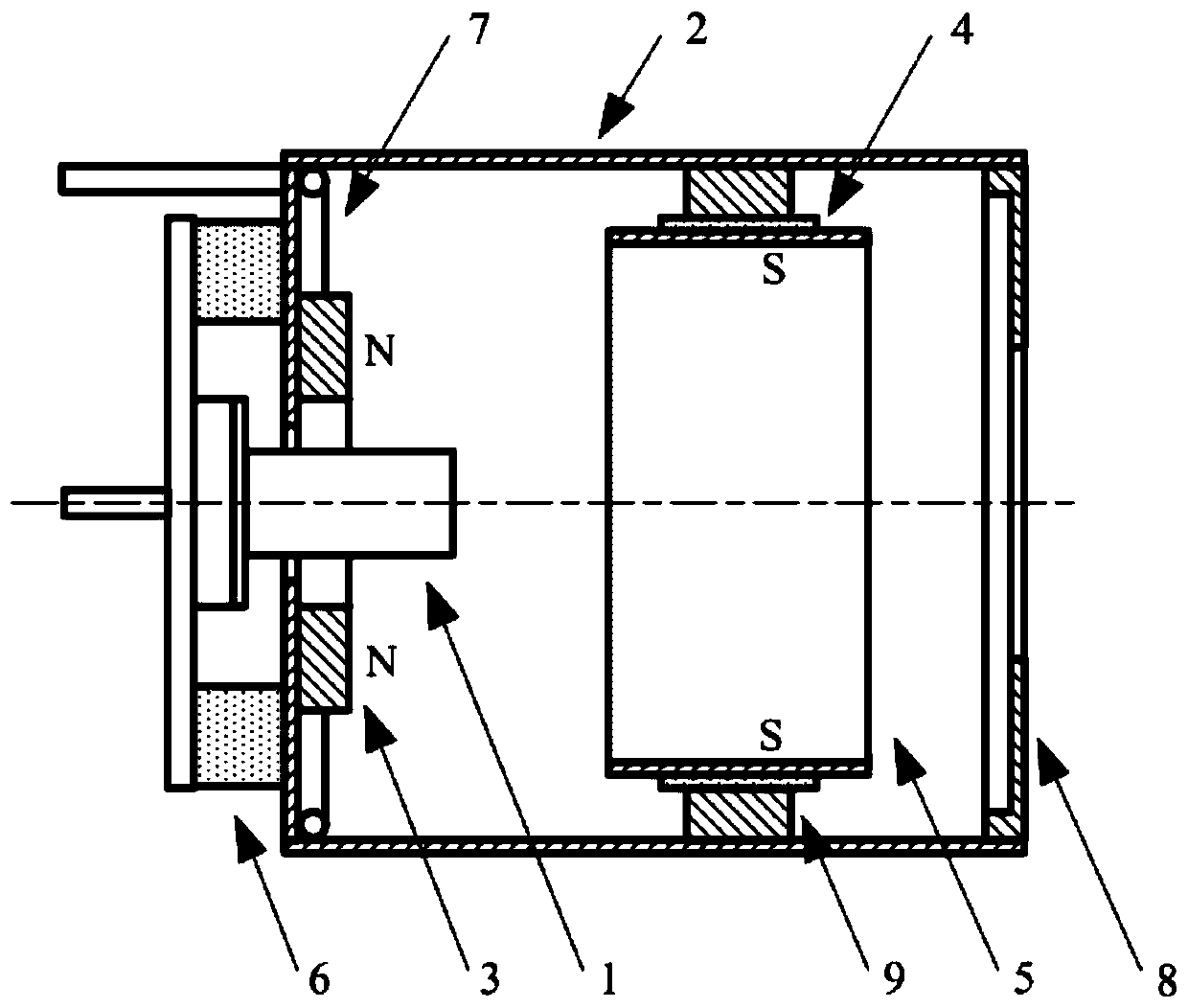

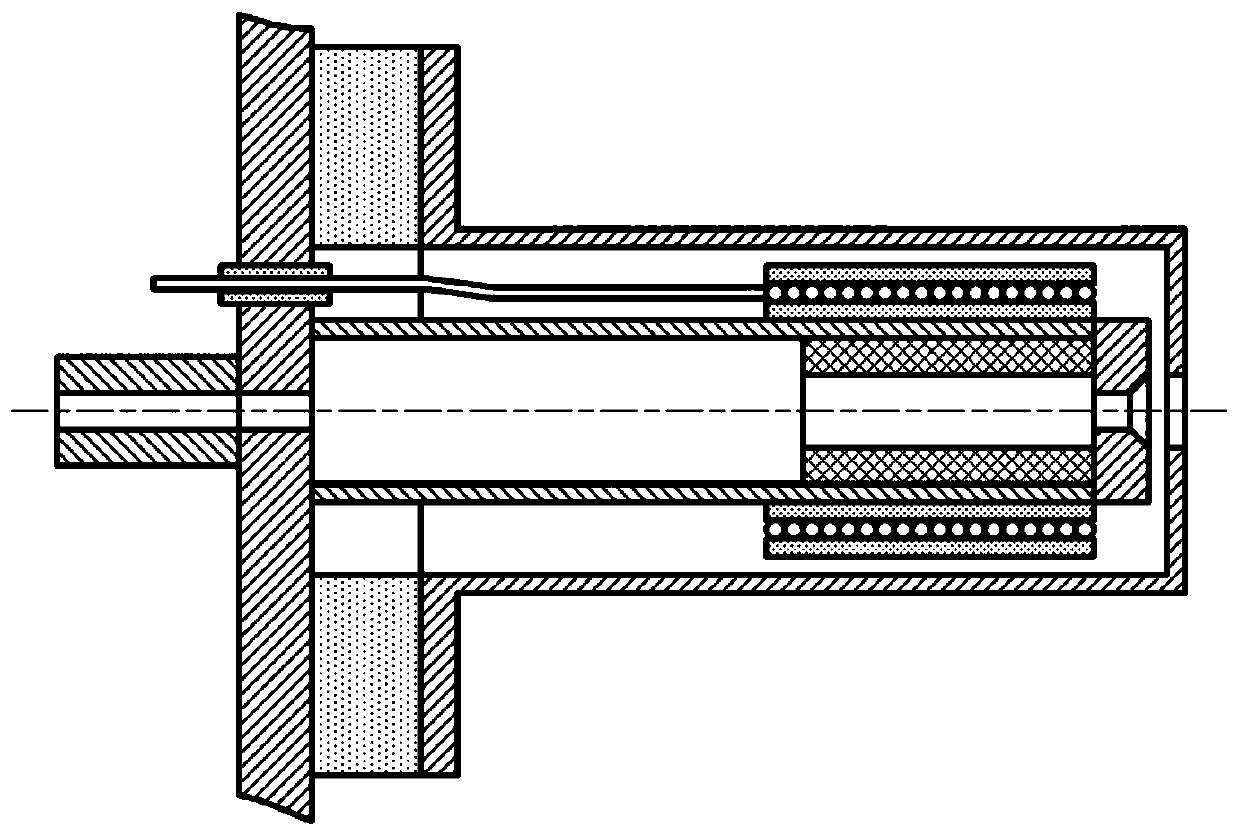

[0027] A plasma contactor with an annular ionization chamber, comprising: a hollow cathode plasma contactor, an ionization chamber housing, a first permanent magnet, a second permanent magnet, mica sheets, an anode housing and an ionization chamber housing insulating ceramics;

[0028] Connection relationship: the ionization chamber shell is a hollow cylinder structure with an open bottom end, and a through hole is opened at the top center of the cylinder; the flange of the hollow cathode plasma contactor is fixed to the ionization chamber shell through the insulating ceramics of the ionization chamber shell Connection; the first permanent magnet and the second permanent magnet are ring structures; the N pole of the first permanent magnet faces the interior of the ionization chamber; the S pole of the second permanent magnet faces the interior of the ionization chamber; the first permanent magnet is fixedly installed on the ionization chamber shell body top inner wall; the seco...

Embodiment 2

[0034] A plasma contactor with an annular ionization chamber, comprising: a hollow cathode plasma contactor, an ionization chamber casing, a first permanent magnet, a second permanent magnet, a mica sheet, an anode casing, an ionization chamber casing insulating ceramics, Secondary air supply pipeline;

[0035] Connection relationship: the ionization chamber shell is a hollow cylinder structure with an open bottom end, and a through hole is opened at the top center of the cylinder; the flange of the hollow cathode plasma contactor is fixed to the ionization chamber shell through the insulating ceramics of the ionization chamber shell Connection; the first permanent magnet and the second permanent magnet are ring structures; the N pole of the first permanent magnet faces the interior of the ionization chamber; the S pole of the second permanent magnet faces the interior of the ionization chamber; the first permanent magnet is fixedly installed on the ionization chamber shell bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com