Restored raisin beverage and preparation method thereof

A production method and technology of raisins, which are applied in the field of food processing, can solve problems such as damage to human health, affecting taste, difficult storage and transportation of grapes, and achieve the effects of reducing production costs and easy storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] S1. Wash the above raw materials, and weigh them according to the number of parts: 100 parts of raisins, 200 parts of water;

[0023] S2. Add 200 parts of water to soak the raisins for 10 minutes;

[0024] S3. Put the soaked container into an ultrasonic cleaning machine for ultrasonication for 1 hour;

[0025] S4. Filter the raisins after ultrasonication, and wash them once with water;

[0026] S5. Put the cleaned raisins into the juice extractor, and then pour the same amount of water as the raisins to squeeze the juice;

[0027] S6. Filter the turbid liquid after squeezing the juice to leave the supernatant;

[0028] S7. Add 0.1 part of sodium citrate, 0.1 part of citric acid, and 0.1 part of potassium sorbate to the remaining supernatant;

[0029] S8. The mixed liquid is bottled, sterilized and capped.

Embodiment 2

[0031] S1. Wash the above raw materials, and weigh them according to the number of parts: 125 parts of raisins, 250 parts of water;

[0032] S2. Add 200 parts of water to soak the raisins for 10 minutes;

[0033] S3. Put the soaked container into an ultrasonic cleaning machine for ultrasonication for 1 hour;

[0034] S4. Filter the raisins after ultrasonication, and wash them once with water;

[0035] S5. Put the cleaned raisins into the juice extractor, and then pour the same amount of water as the raisins to squeeze the juice;

[0036] S6. Filter the turbid liquid after squeezing the juice to leave the supernatant;

[0037] S7. Add 0.15 parts of sodium citrate, 0.15 parts of citric acid, and 0.125 parts of potassium sorbate to the remaining supernatant;

[0038] S8. The mixed liquid is bottled, sterilized and capped.

Embodiment 3

[0040] S1. Wash the above raw materials, and weigh them according to the number of parts: 150 parts of raisins, 300 parts of water;

[0041] S2. Add 200 parts of water to soak the raisins for 10 minutes;

[0042] S3. Put the soaked container into an ultrasonic cleaning machine for ultrasonication for 1 hour;

[0043] S4. Filter the raisins after ultrasonication, and wash them once with water;

[0044] S5. Put the cleaned raisins into the juice extractor, and then pour the same amount of water as the raisins to squeeze the juice;

[0045] S6. Filter the turbid liquid after squeezing the juice to leave the supernatant;

[0046] S7. Add 0.2 part of sodium citrate, 0.2 part of citric acid, and 0.15 part of potassium sorbate to the remaining supernatant;

[0047] S8. The mixed liquid is bottled, sterilized and capped.

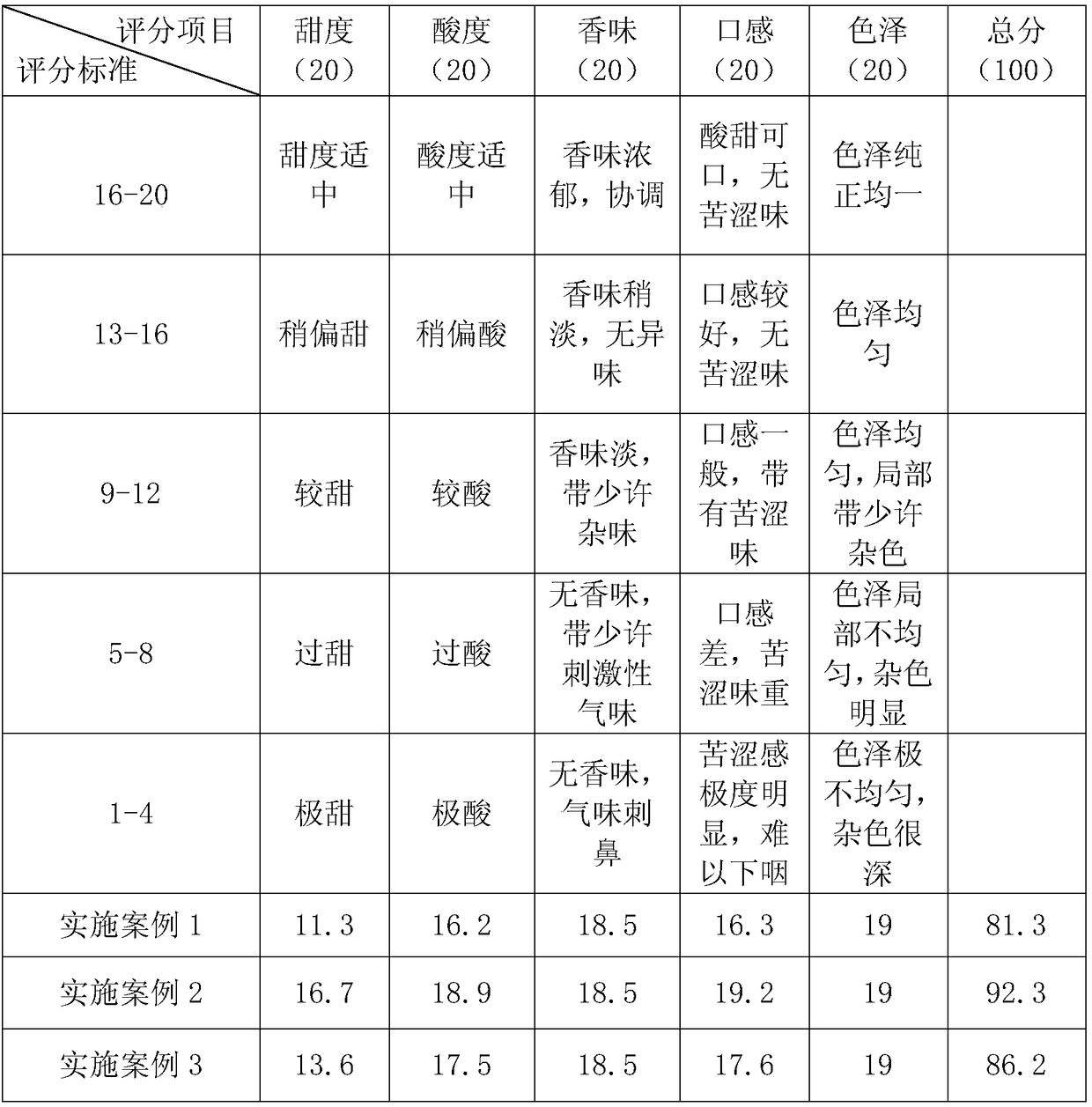

[0048] Carry out sensory evaluation to embodiment 1-3 reconstituted raisin beverage drink, the result is as follows table 1:

[0049] Table 1: Sensory evaluati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com