A stirrer for microbe fermentation

A microbial fermentation and stirring device technology, applied in the biological field, can solve the problems of small stirring range, insufficient and uniform stirring, etc., and achieve the effect of increasing the stirring range, ingenious structure, and improving stirring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

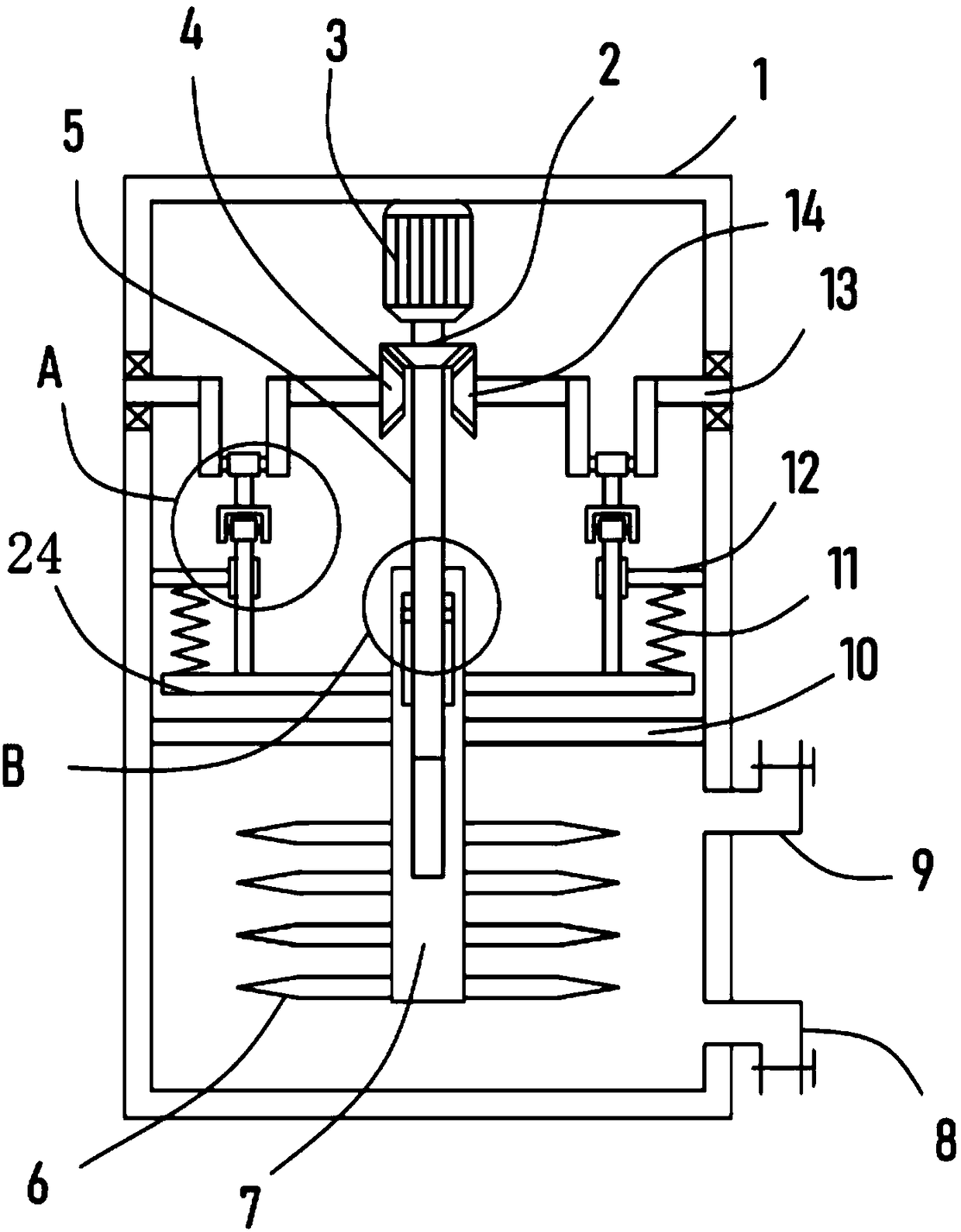

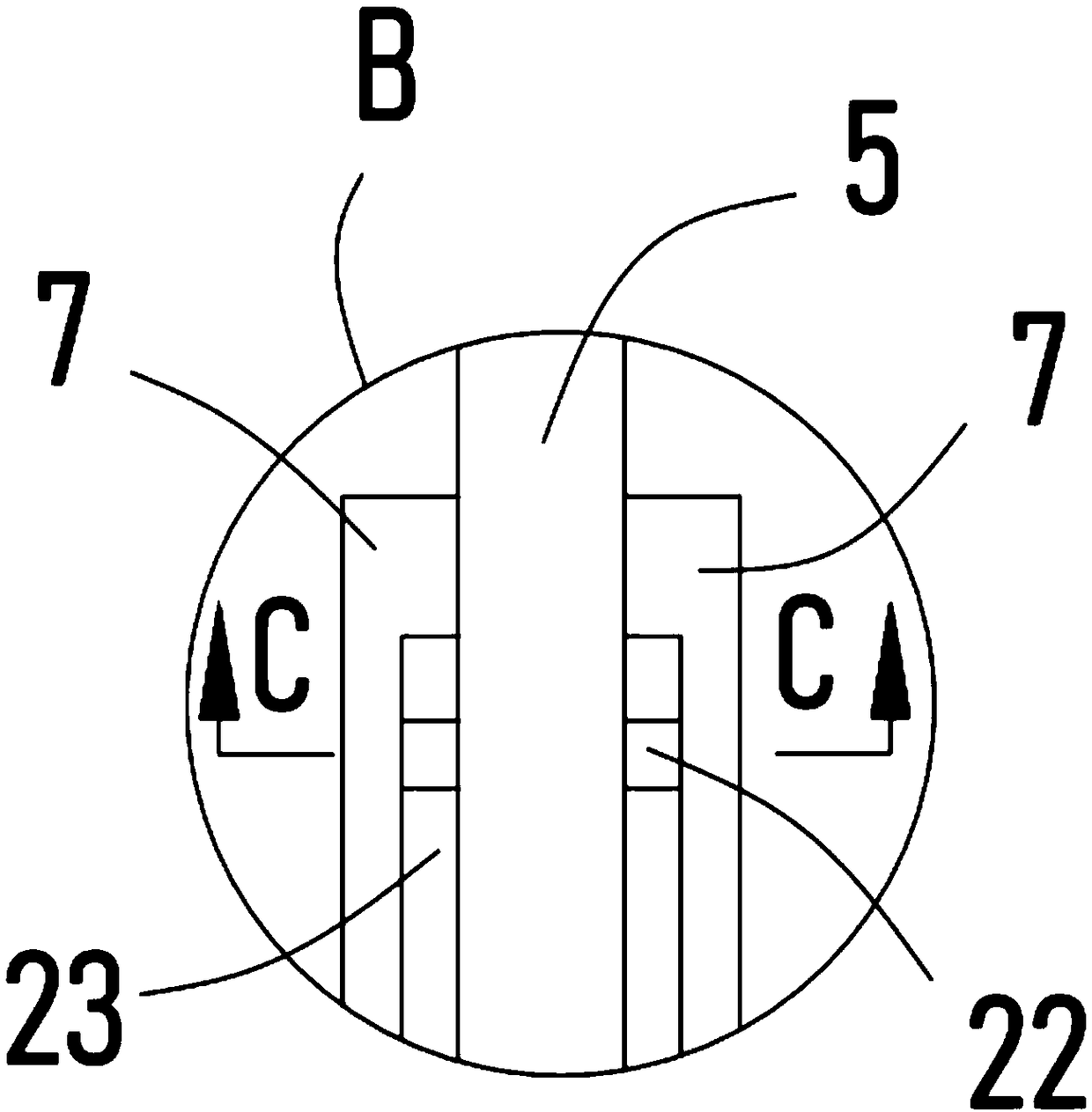

[0022] see Figure 1-4 A stirring device for microbial fermentation, comprising a box body 1, a partition plate 10 is horizontally and fixedly installed in the box body 1, the partition plate 10 divides the box body 1 into upper and lower parts, and the part below the partition plate 10 is used to contain microorganisms Fermentation raw materials, further, the feed pipe 9 and the discharge pipe 8 are installed on the box body 1, the microbial fermentation raw material can be injected into the box body 1 through the feed pipe 9, and the microbial fermentation after stirring can be discharged through the discharge pipe 8 raw material.

[0023] A driving motor 3 is fixedly installed in the box body 1, and the output shaft of the driving motor 3 is coaxially fixedly installed with a vertically arranged driving shaft 5, and the driving shaft 5 is covered with a stirring sleeve 7 that is slidably connected with the partition plate 10. A plurality of stirring blades 6 are evenly and...

Embodiment 2

[0027] On the basis of Embodiment 1, in addition, two driven shafts 13 are rotatably arranged in the box body 1, and the driven bevel gears meshingly connected with the driving bevel gear 2 are respectively sleeved and fixedly installed on the two driven shafts 13. I4 and driven bevel gear II14.

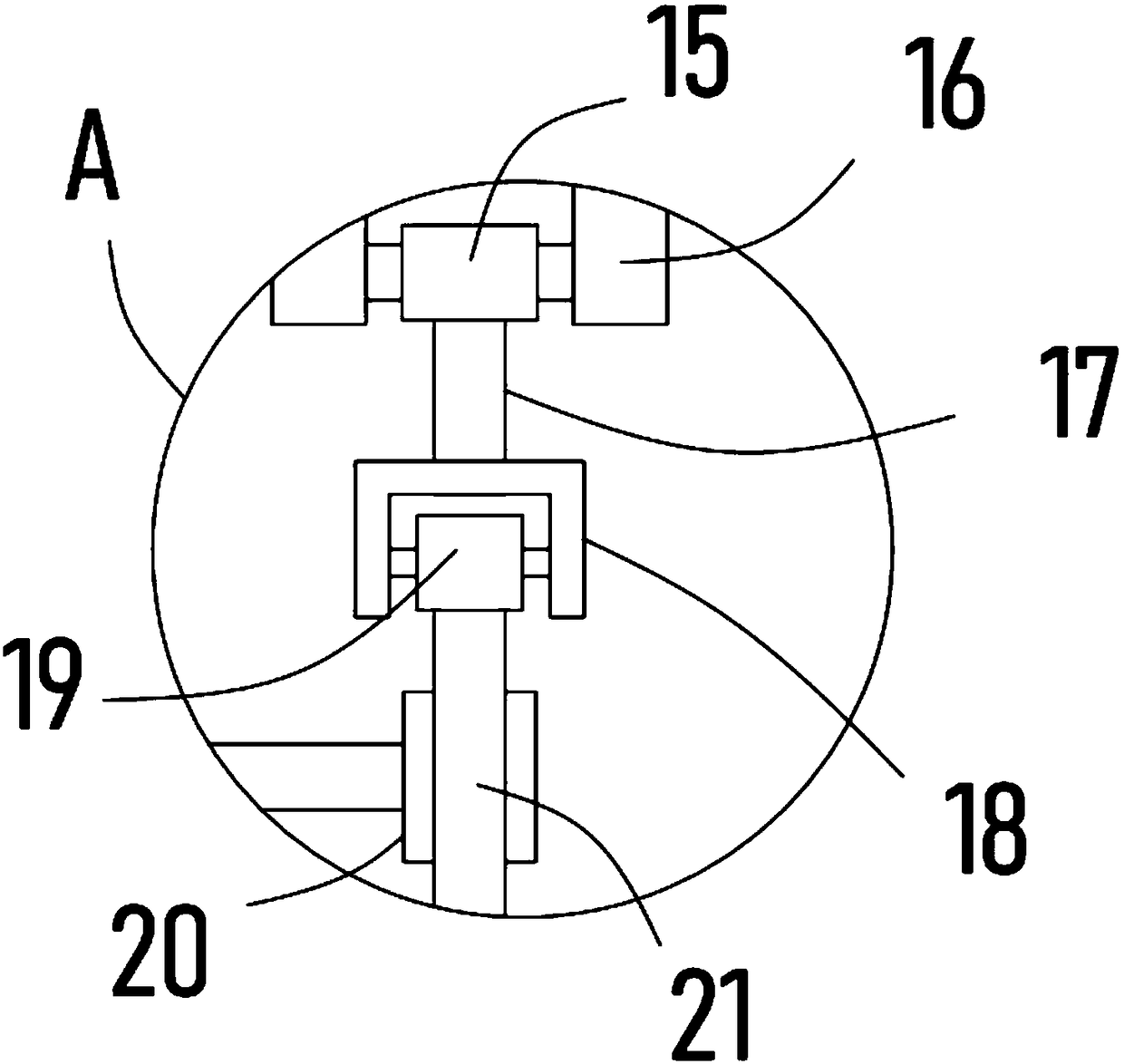

[0028] Further, a crankshaft 16 is fixedly installed on the driven shaft 13, a collar 15 is sleeved on the crankshaft 16, a connecting rod 17 is fixedly installed on the collar 15, an n-shaped frame 18 is fixed on the bottom of the connecting rod 17, and an n-shaped frame 18 A connecting block 19 is hinged on the top, and a slide bar 21 is vertically fixedly installed at the lower end of the connecting block 19 , and a transmission plate 24 abutting against the lower end of the slide bar 21 is fixed horizontally on the side wall of the stirring sleeve 7 .

[0029] The driving bevel gear 2 is driven by the driving shaft 5, and then drives the driven bevel gear I4 and the driven bevel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com