Chromium-molybdenum steel plate used for large-caliber single-channel straight weld joint pressure pipeline and production method of chromium-molybdenum steel plate

A technology of pressure pipes and straight welds, which is applied in the field of chrome-molybdenum steel plates for large-diameter single-pass straight weld pressure pipes, which can solve the problems of being unable to manufacture super-large-diameter pipes with a single weld of more than 1600mm, and improve safety and operating efficiency , the effect of uniform performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below by embodiment the present invention will be further described.

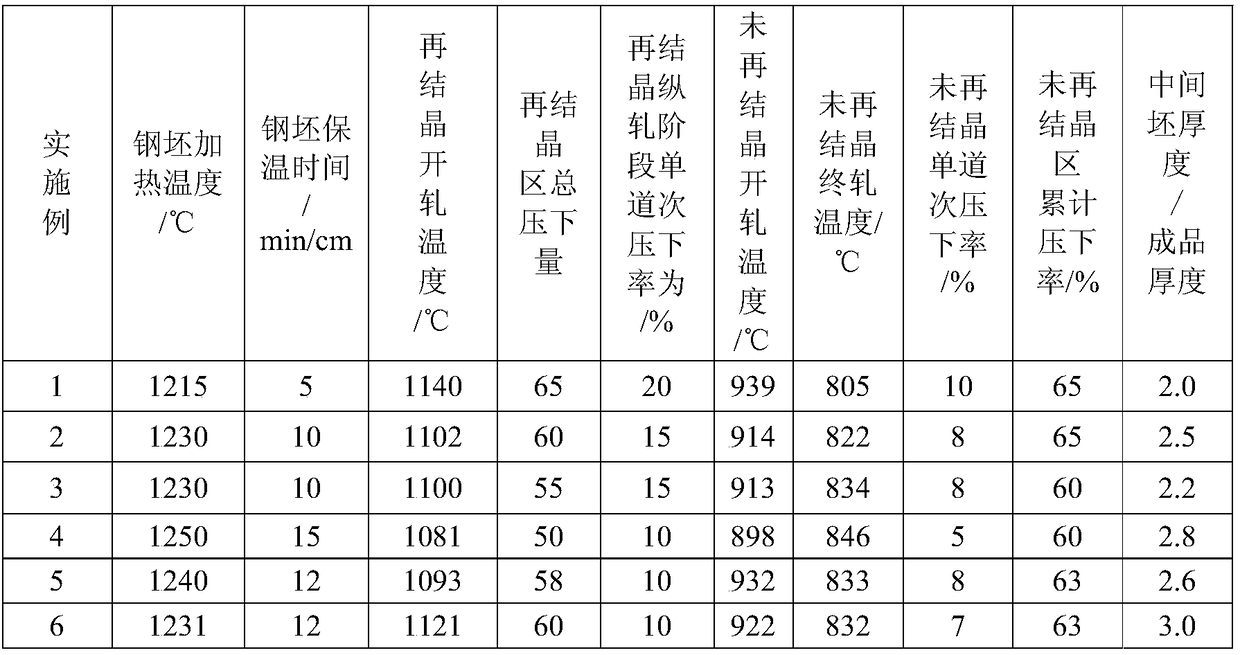

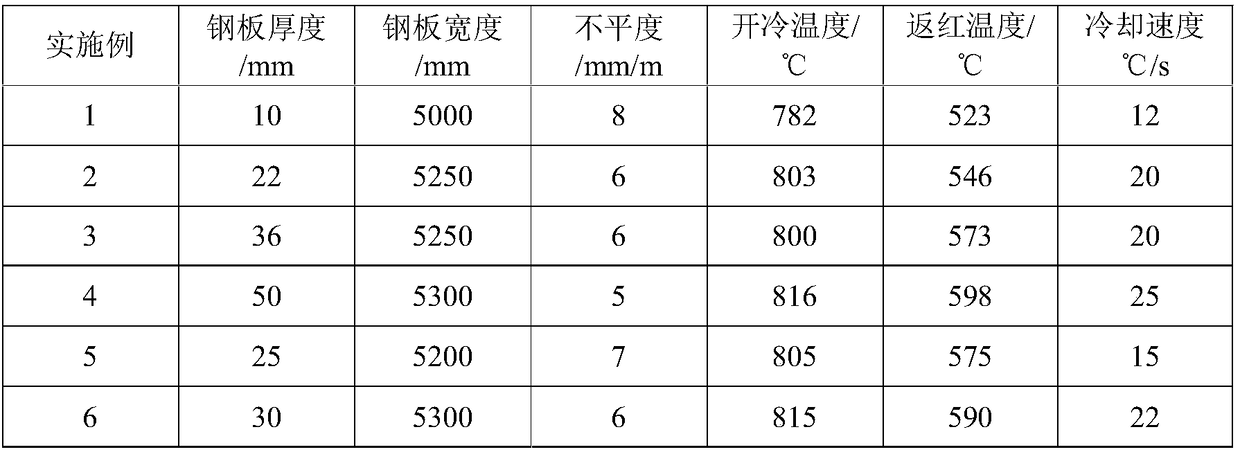

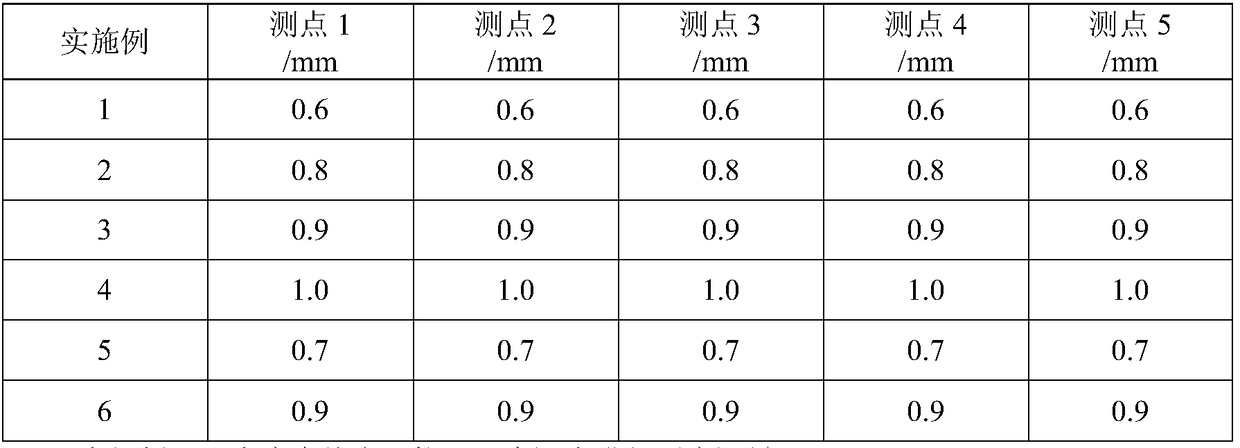

[0030] In the embodiment of the present invention, according to the component ratio of the technical solution, pretreatment of molten iron—converter smelting—external refining—continuous casting—slab heating—controlled rolling and cooling—heat treatment is performed. The composition of the steel of the embodiment of the present invention is shown in Table 1. The specifications of the steel billet in the embodiment of the present invention are shown in Table 2. The main control rolling parameters of the steel in the embodiment of the present invention are shown in Table 3. The main control cooling process parameters of the steel in the embodiment of the present invention are shown in Table 4. The heat treatment parameters of the steel in the embodiment of the present invention are shown in Table 5. The lateral thickness tolerance of the steel of the embodiment of the present invention is shown in T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com