A method for simulating/predicting catalytic activity of catalysts in surface catalytic reactions and application thereof

A technology of surface catalysis and catalytic activity, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as unsatisfactory catalytic materials and catalyst design gaps, and achieve experimental cost savings, high accuracy, and Accurately Predicted Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

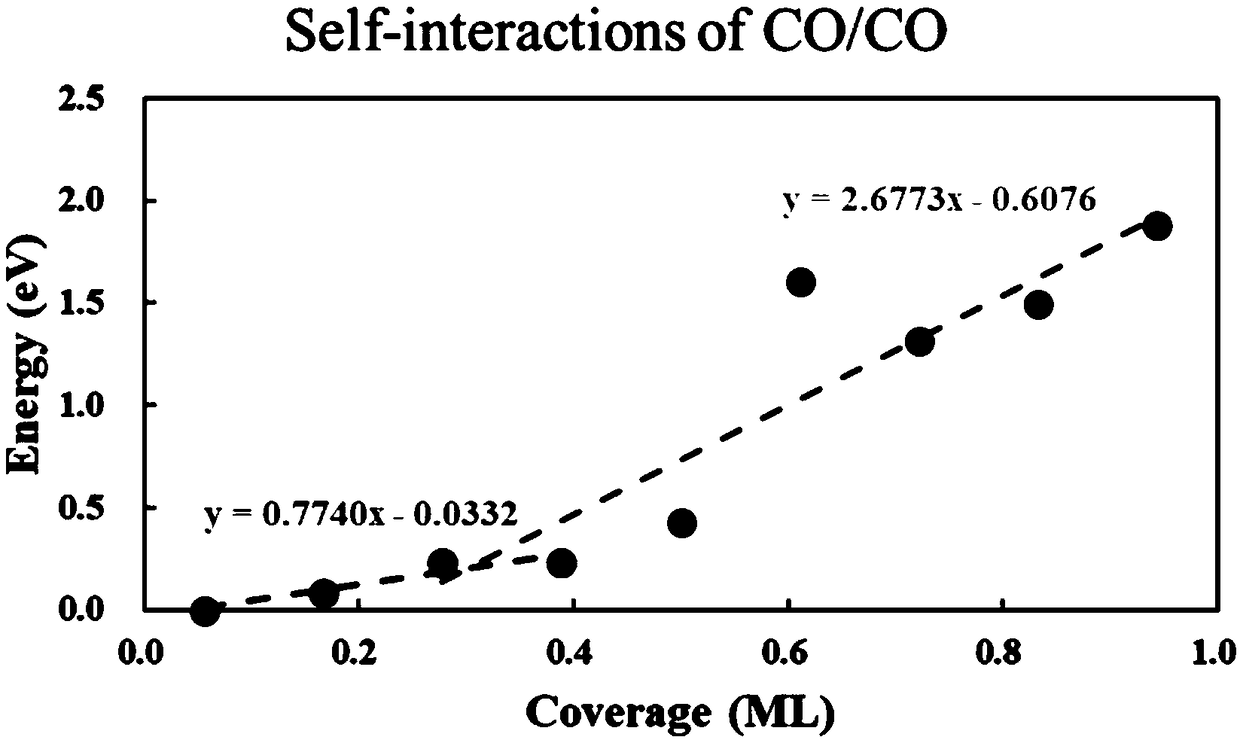

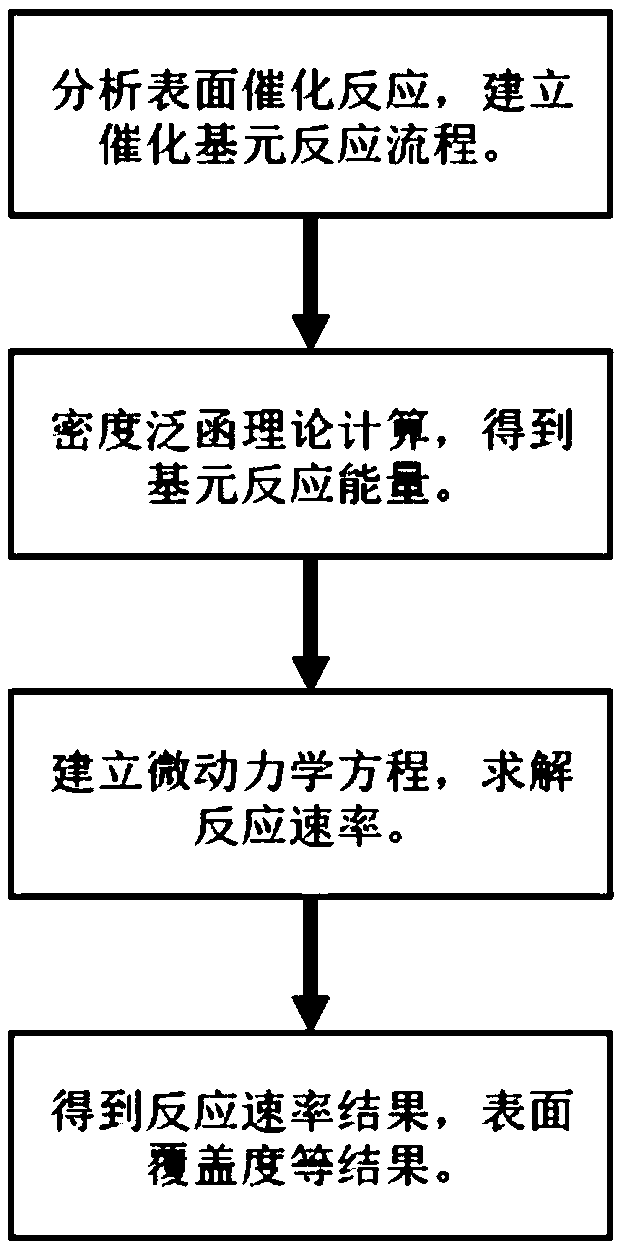

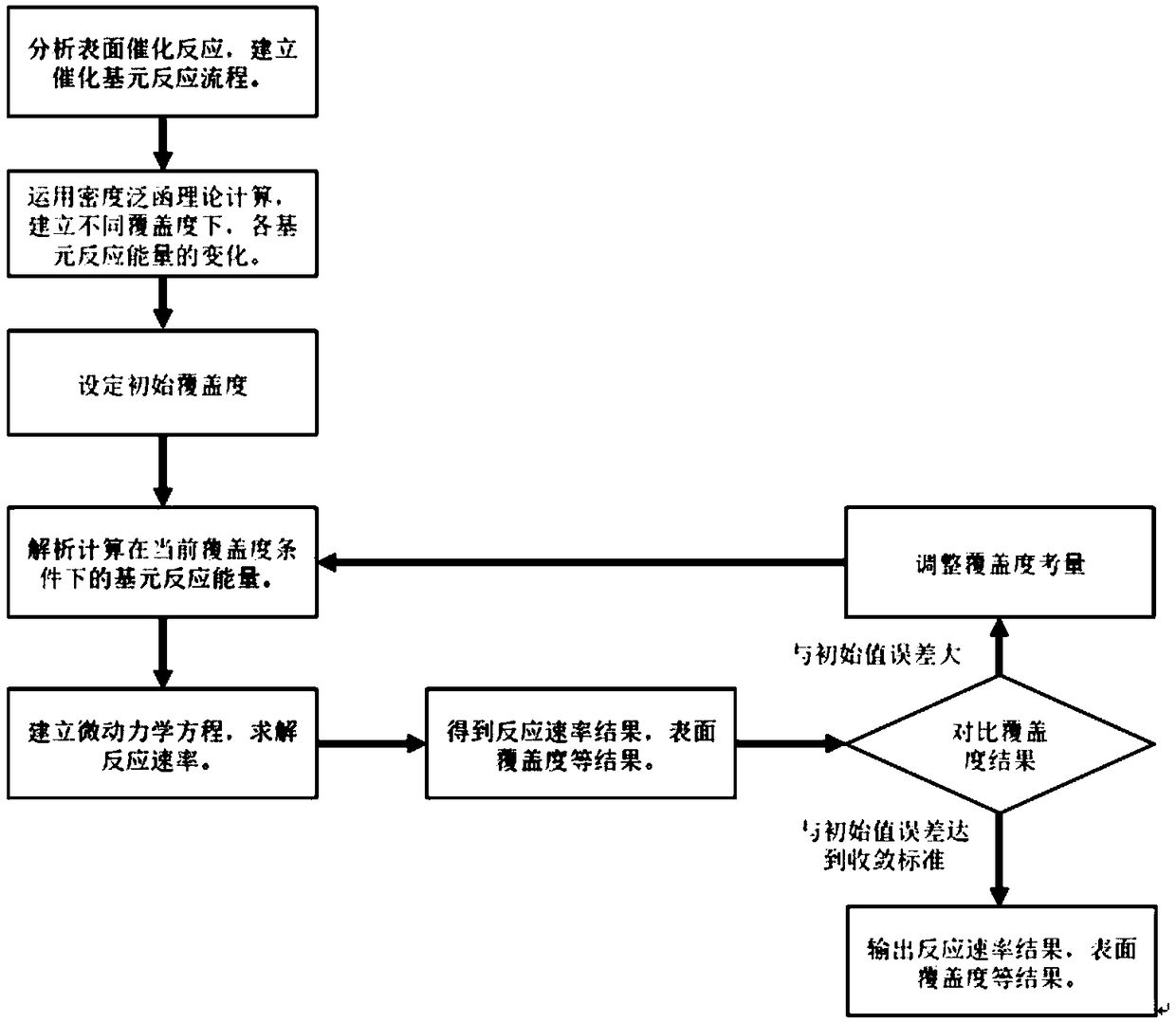

Method used

Image

Examples

Embodiment 1

[0105] The method for simulating / predicting the catalyst catalytic activity in the surface catalytic reaction of the present invention is used to predict the activity of the catalytic reaction, including:

[0106] Using the above method to stably solve the activity of CO oxidation on the surface of Rh(111) (this system is the reference system for method development), the operating conditions of the catalytic reaction include: reaction temperature: 600K, pressure: 8 Torr, partial pressure ratio: CO / o 2 =1.

[0107] Figure 4 A schematic diagram showing the activity prediction results of carbon monoxide oxidation on the surface of Rh(111) in Example 1 of the present invention; Figure 4 Among them, point A is the prediction result of traditional microdynamics, point B is the activity obtained by the most simplified coverage self-consistent algorithm, point C is the activity obtained by the self-consistent coverage algorithm considering both self-influence and interaction, and...

Embodiment 2

[0110] The method for simulating / predicting the catalyst catalytic activity in the surface catalytic reaction of the present invention is used to predict the activity of the catalytic reaction, including:

[0111] In the Fischer-Tropsch reaction, the operating conditions of the reaction include: reaction temperature: 500K, total pressure: 10bar, partial pressure H 2 / CO=2, predicted the activity of CO on the stepped cobalt surface, and its activity was far better than the prediction of traditional results and close to the experimental results.

[0112] Figure 5 Shows the schematic diagram of the predicted results of Fischer-Tropsch reaction surface catalytic activity provided by Example 2 of the present invention, wherein the left (short) column represents the activity obtained by the coverage self-consistent method, and the right (long) column represents the traditional microkinetics The activity obtained, the two dotted lines in the figure represent the activity range obta...

Embodiment 3

[0115] The method for simulating / predicting the catalyst catalytic activity in the surface catalytic reaction of the present invention is used to predict the activity of the catalytic reaction, including:

[0116] Using the above method to stably solve the selectivity of acetylene hydrogenation catalytic reaction process on Pd(111) surface, the results are far better than the prediction of traditional theoretical calculation results and perfectly fit with the experimental results.

[0117] Table 1 shows the selectivity of acetylene during the catalytic hydrogenation reaction on Pd(111) surface. As can be seen from Table 1, the theoretical calculation results in the past, under 350K, the ethylene selectivity is about 5%; adopt the result predicted by the method of the present invention (considering the self-consistent coverage), the ethylene selectivity is about 75.91%; experimental results , under reducing atmosphere (100ppm of CO feed), the ethylene selectivity can reach abou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com