Method for preparing fermented bean curd by lactobacillus casei

A technology of Lactobacillus casei and tofu, applied to Lactobacillus, bacteria used in food preparation, dairy products, etc., can solve problems such as difficult standardization of processes and complex microbial flora

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

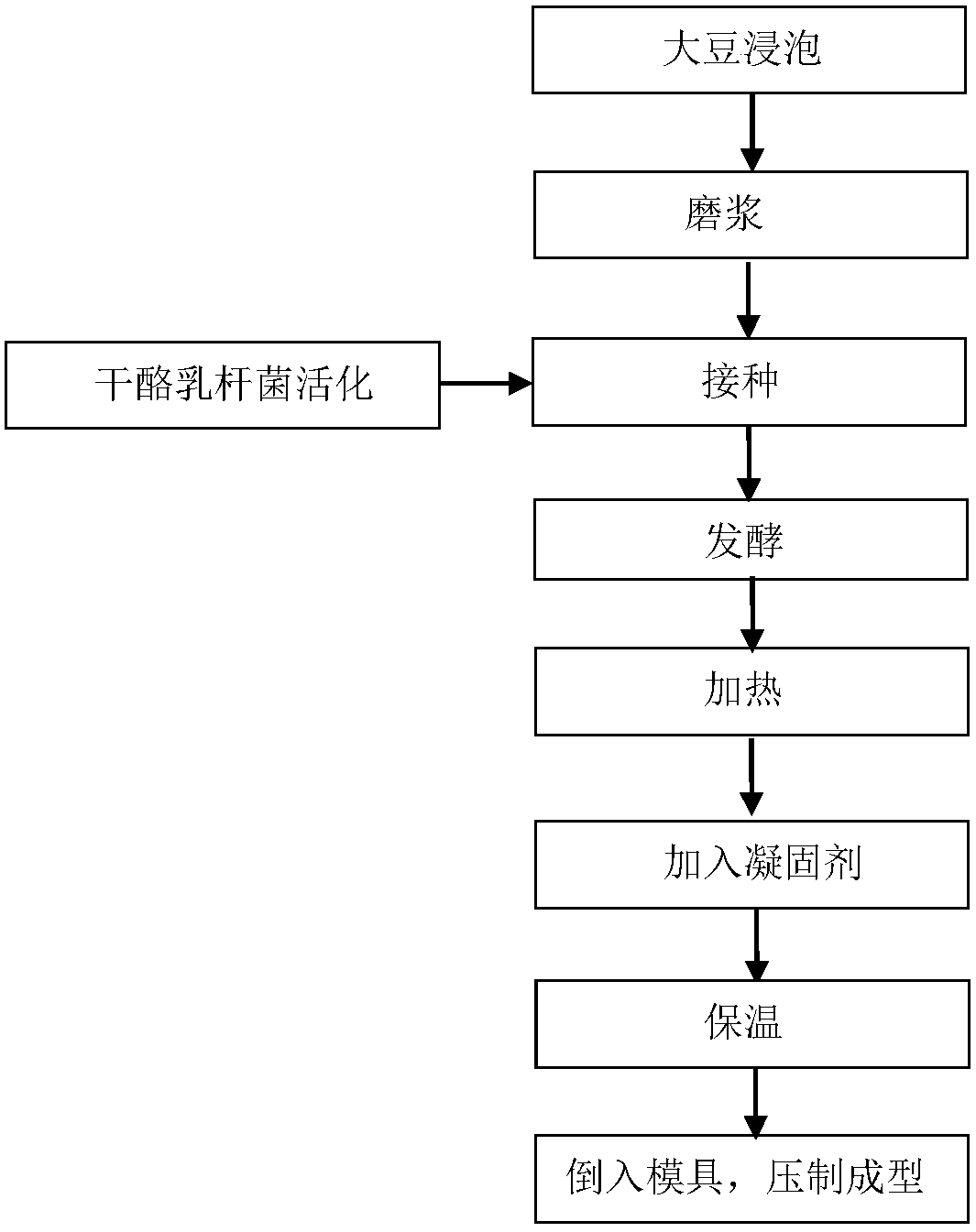

Image

Examples

Embodiment 1

[0016] The making of embodiment 1 fermented bean curd

[0017] 1. Preparation of strains Lactobacillus casei, which is commonly used in fermenting soybean products, was selected for the following experimental operations.

[0018] 2. Prepare and sterilize the strain activation medium in step 1: the MRS medium is used for the activation and cultivation of Lactobacillus casei, and it is autoclaved at 121° C. for 15 minutes, and it is used for later use.

[0019] 3. Activation and subculture of bacterial strains: Inoculate the frozen bacterial classification in step 1 into the liquid medium of step 2 at an inoculum size of 4%, cultivate at 37° C. for 12 hours, subculture twice, and obtain culture solution for subsequent use.

[0020] 4. Preparation of soybean milk: Grind soybeans and water at a medium speed for 1 minute at a ratio of 1:5, filter through a 100-mesh sieve, and sterilize by autoclaving at 115°C for 10 minutes for later use.

[0021] 5. Preparation of fermented soymi...

Embodiment 2

[0023] The making of embodiment 2 fermented tofu

[0024] 1. Preparation of strains Lactobacillus casei, which is commonly used in fermenting soybean products, was selected for the following experimental operations.

[0025] 2. Prepare and sterilize the strain activation medium in step 1: the MRS medium is used for the activation and cultivation of Lactobacillus casei, and it is autoclaved at 121° C. for 15 minutes, and it is used for later use.

[0026] 3. Activation and subculture of bacterial strains: inoculate the frozen bacterial classification in step 1 into the liquid medium of step 2 with an inoculum size of 4%, cultivate at 37° C. for 12 hours, subculture 3 times, and obtain culture solution for subsequent use.

[0027] 4. Preparation of soybean milk: Grind soybeans and water at a medium speed for 3 minutes at a ratio of 1:5, filter through a 100-mesh sieve, autoclave at 115°C for 10 minutes, and set aside.

[0028] 5. Preparation of fermented soymilk: take 2% bacter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com