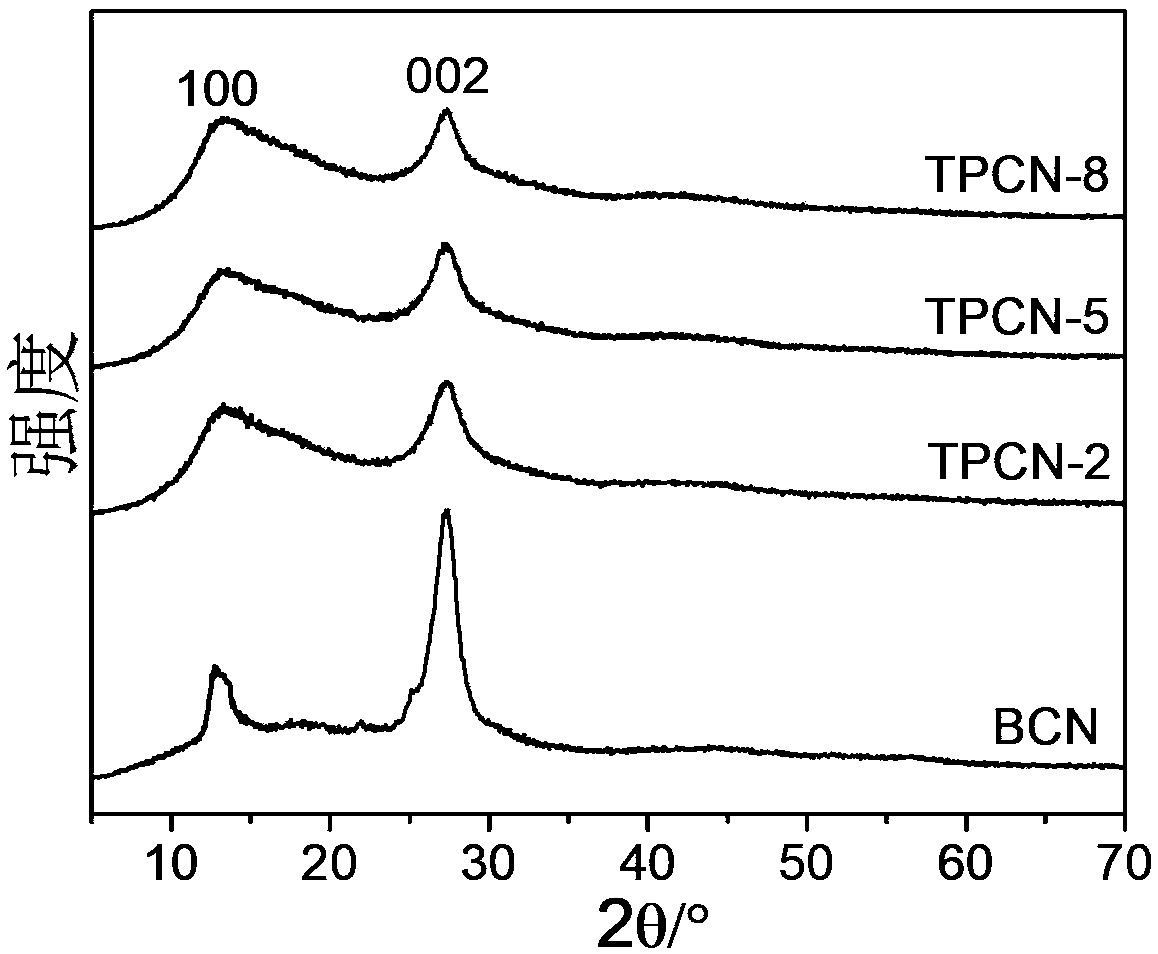

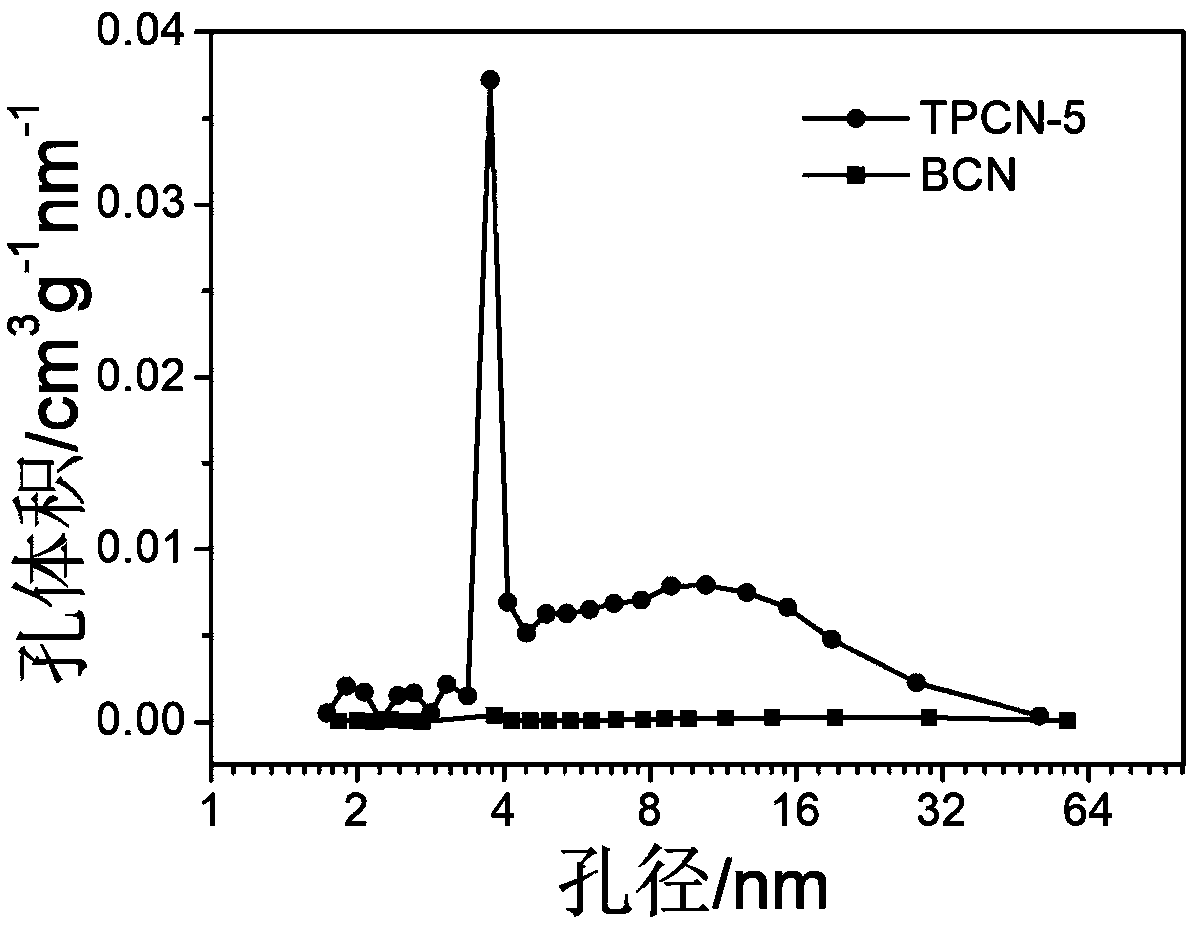

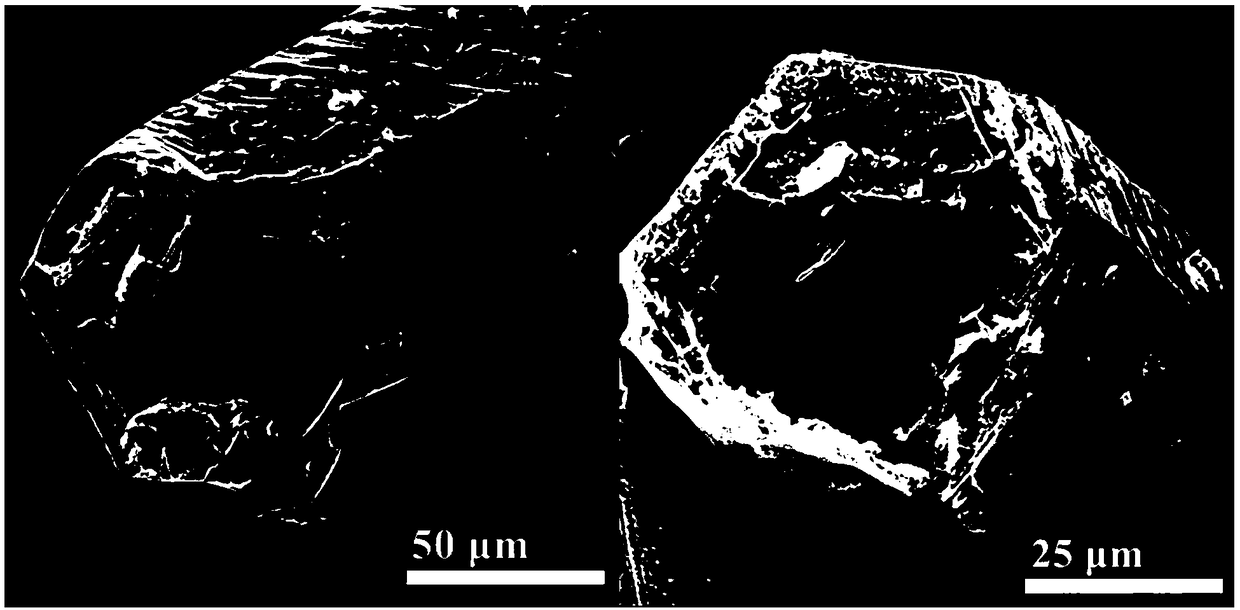

Porous tubular C3N4 photocatalyst and preparation method thereof

A photocatalyst, C3N4 technology, applied in the field of photocatalytic materials, can solve the problems of high cost and harsh preparation conditions, and achieve the effects of cheap raw materials, reduced product cost, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A porous tubular C 3 N 4 Photocatalyst, the preparation method of described photocatalyst comprises the steps:

[0034]Weigh 2.0g melamine and place it in a round-bottomed flask, then add 90mL of acetic acid aqueous solution with a concentration of 2% (v / v), 5% (v / v), and 8% (v / v), and place the round-bottomed flask Put it into an oil bath, heat and reflux at a constant temperature of 100°C for 60 minutes; then pour the solution in the round bottom flask into a polytetrafluoroethylene liner while it is still hot, put it into a stainless steel water heater, and heat it at a constant temperature of 180°C for 10 hours. Cool the hot kettle naturally, centrifuge the dispersion liquid in the liner, wash the precipitate, dry and grind, and the product is the supramolecular precursor; put the supramolecular precursor prepared above in the crucible, in the nitrogen atmosphere in the tube furnace Calcination at low temperature, from room temperature to 520 ° C, the heating rate...

Embodiment 2

[0037] A porous tubular C 3 N 4 Photocatalyst, the preparation method of described photocatalyst comprises the steps:

[0038] Weigh 2.0g of melamine and place it in a round bottom flask, then add 40mL of 0.1% (v / v) acetic acid aqueous solution, put the round bottom flask in an oil bath, heat and reflux at a constant temperature of 50°C for 5 minutes; Pour the solution in the round-bottomed flask into a polytetrafluoroethylene liner, put it into a stainless steel hydrothermal kettle, heat it at a constant temperature of 120°C for 8 hours, wait for the hydrothermal kettle to cool naturally, centrifuge the dispersion in the inner tank, and wash the precipitate , dry and grind, and the product is the supramolecular precursor; put the above-prepared supramolecular precursor in a crucible, calcinate it in a nitrogen atmosphere in a tube furnace, and raise the temperature from room temperature to 450°C with a heating rate of 1°C·min -1 , at 450°C for 1 hour, after natural cooling,...

Embodiment 3

[0040] A porous tubular C 3 N 4 Photocatalyst, the preparation method of described photocatalyst comprises the steps:

[0041] Weigh 2.0 g of melamine and place it in a round bottom flask, then add 400 mL of 50% (v / v) acetic acid aqueous solution, put the round bottom flask in an oil bath, heat and reflux at a constant temperature of 150°C for 300 minutes; Pour the solution in the round bottom flask into a polytetrafluoroethylene liner, put it into a stainless steel hydrothermal kettle, heat at a constant temperature of 200°C for 16 hours, wait for the hydrothermal kettle to cool naturally, centrifuge the dispersion in the inner tank, and wash the precipitate , dried and ground, and the product is the supramolecular precursor; the supramolecular precursor prepared above was placed in a crucible, calcined in a nitrogen atmosphere in a tube furnace, and the temperature was raised from room temperature to 550°C with a heating rate of 8°C·min -1 , at a constant temperature of 55...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com