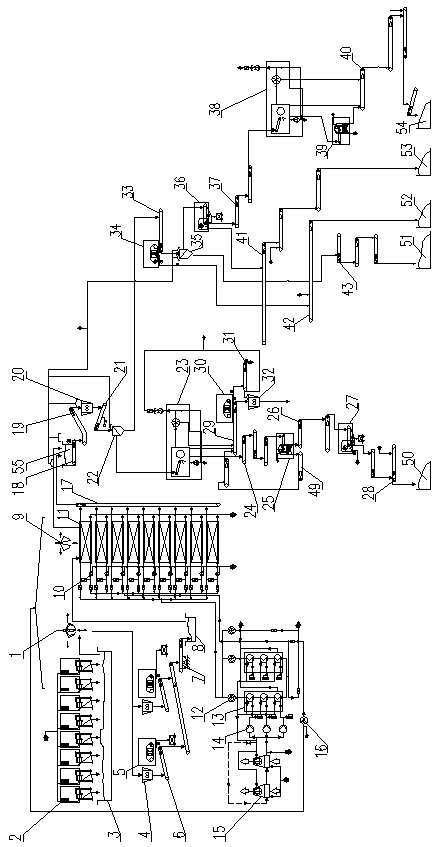

Household waste recycling system

A treatment system and domestic waste technology, which is applied in the field of domestic waste resource treatment system, can solve the problems of unfavorable working environment and work intensity of operators, and achieve the effects of high resource utilization, increased automation, and improved urban environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0037] The grab type of the drying bin grab crane 9 is a double gripper, and it is also equipped with a grab handle for opening the top cover of the drying bin. The grab crane 9 of the drying warehouse mainly has the following tasks:

[0038](1) Transport the pre-crushed garbage from the pre-drying buffer bin 8 to the drying bin 11;

[0039] (2) Lift or lower the top cover of the drying bin 11;

[0040] (3) Use cleaning equipment to clean the top cover of the drying chamber 11;

[0041] (4) The dried garbage is transported from the drying bin 11 to the buffer bin 55 after drying, and discharged by the stepping feeder 18 .

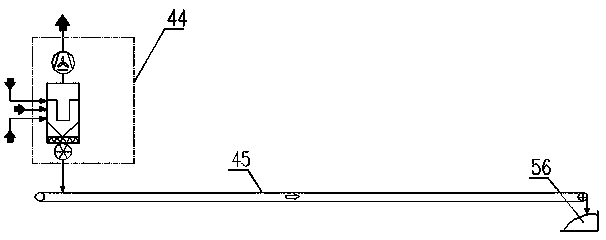

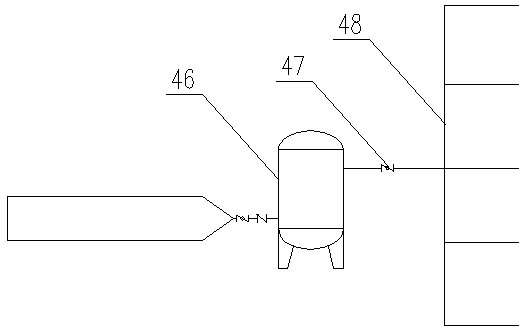

[0042] A controllable exhaust system can be installed behind the drying chamber 11. The exhaust system is equipped with fans, exhaust pipes, power distribution rooms, etc. Each drying chamber can be regarded as an independent operating system. These modules can be combined into a large drying system.

[0043] The air flow for drying can mainly absorb th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com