Steel ladle moulding bed for steel ladle inner lining integral casting and steel ladle inner lining integral casting method

An integral pouring and ladle technology is applied in the field of ladle tire mould ladle integral pouring for ladle lining integral casting, which can solve the problems of long construction time, low construction machinery level, low construction efficiency, etc. The effect of labor intensity of workers, improvement of turnover efficiency, and improvement of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

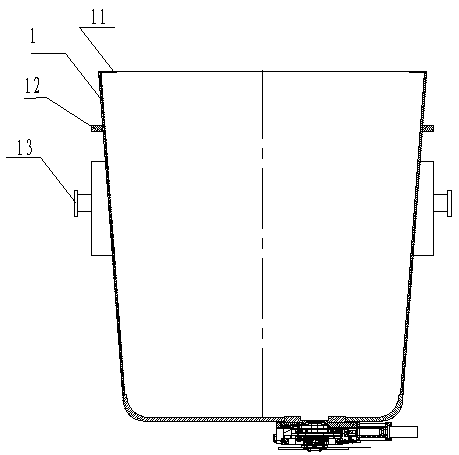

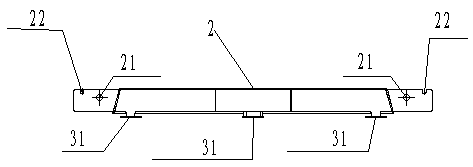

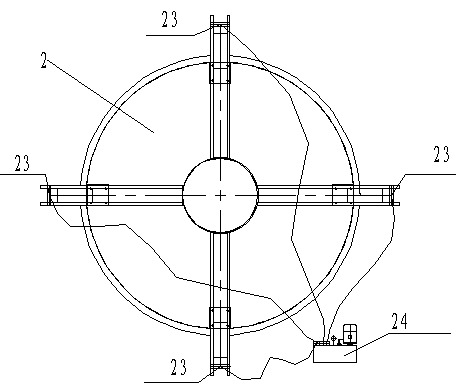

[0043] combine Figure 1-Figure 6It can be seen that the tire mold for integral pouring of the ladle lining of the present invention is composed of the main body 4 of the conical table body connected with the circular top cover 2; the bottom of the main body 4 is provided with an inclination angle, and a vibration motor 41 is installed inside; the top cover 2 is an installation aid part, four support beams 23 are set in the direction of the two centerlines, the support beams 23 are used to cooperate with the ladle edge 11, and the fastening hydraulic rods 25 are suspended on the support beams 23; the top cover 2 and the main body 4 are used Connector 3 for connection; also includes compressed air demoulding system, hydraulic control system.

[0044] The top cover connector 3 is to weld the upper mounting plate 31 on the top cover and the lower mounting plate and the fixing groove on the tire mold, install a metal damper in the fixing groove, and use bolts to connect the upper ...

Embodiment 2

[0055] A ladle lining integral pouring method, the specific steps are as follows: First, apply a layer of butter evenly on the outer surface of the tire mold as a release agent, then lift the tire mold and place it in the ladle shell, and place it carefully according to the inclined direction of the tire mold After completion, install and fasten the hydraulic rod to connect the tire mold with the steel cladding shell, and use the hydraulic station to fasten the tire mold to complete the installation work; when pouring, the pouring material is poured from the bottom to the top, and the part is used according to the pouring position. The vibrating motor vibrates. After the entire pouring is completed, turn on all the vibrating motors to vibrate for 3 to 5 minutes according to the process requirements; 3 to 8 hours after the construction is completed is the starting time of the tire mold; when starting, first connect the compressed air demoulding system, according to The process r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com