Cast-in-place polystyrene granular foaming concrete dispersion construction system and method

A technology of polystyrene particles and foamed concrete, applied in chemical instruments and methods, clay preparation devices, mixing operation control, etc. and other problems, to achieve the effect of improving production and construction efficiency, light weight and less foam loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

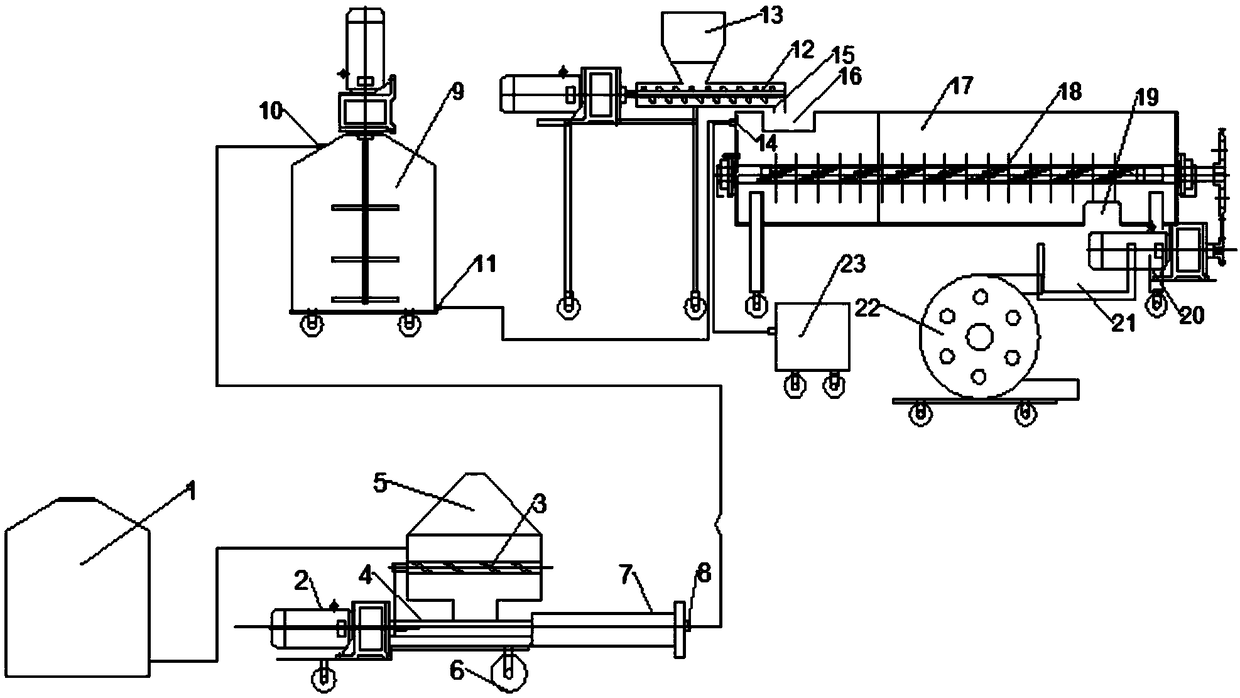

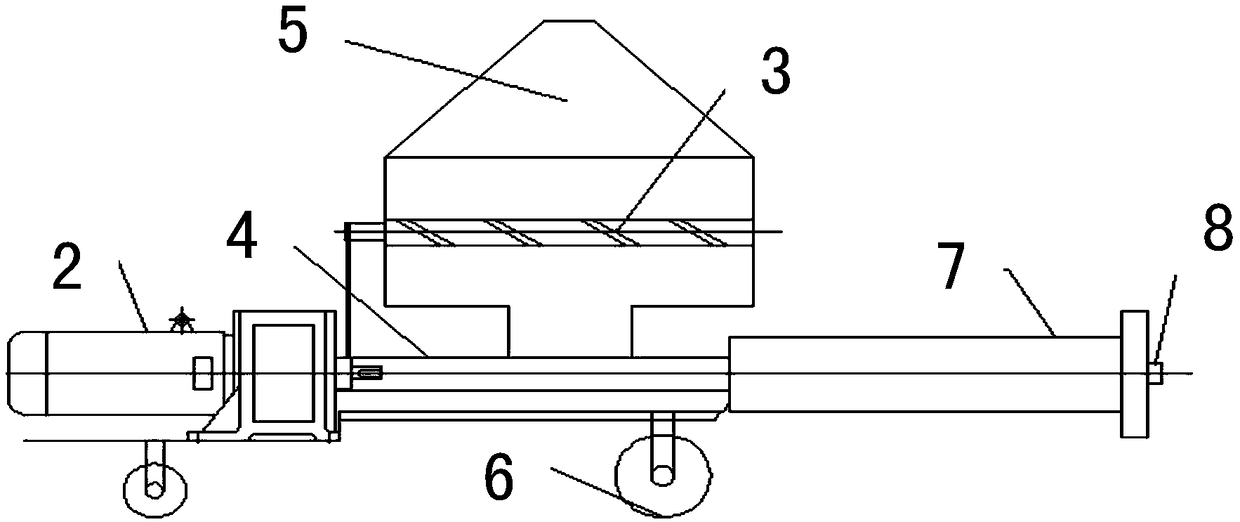

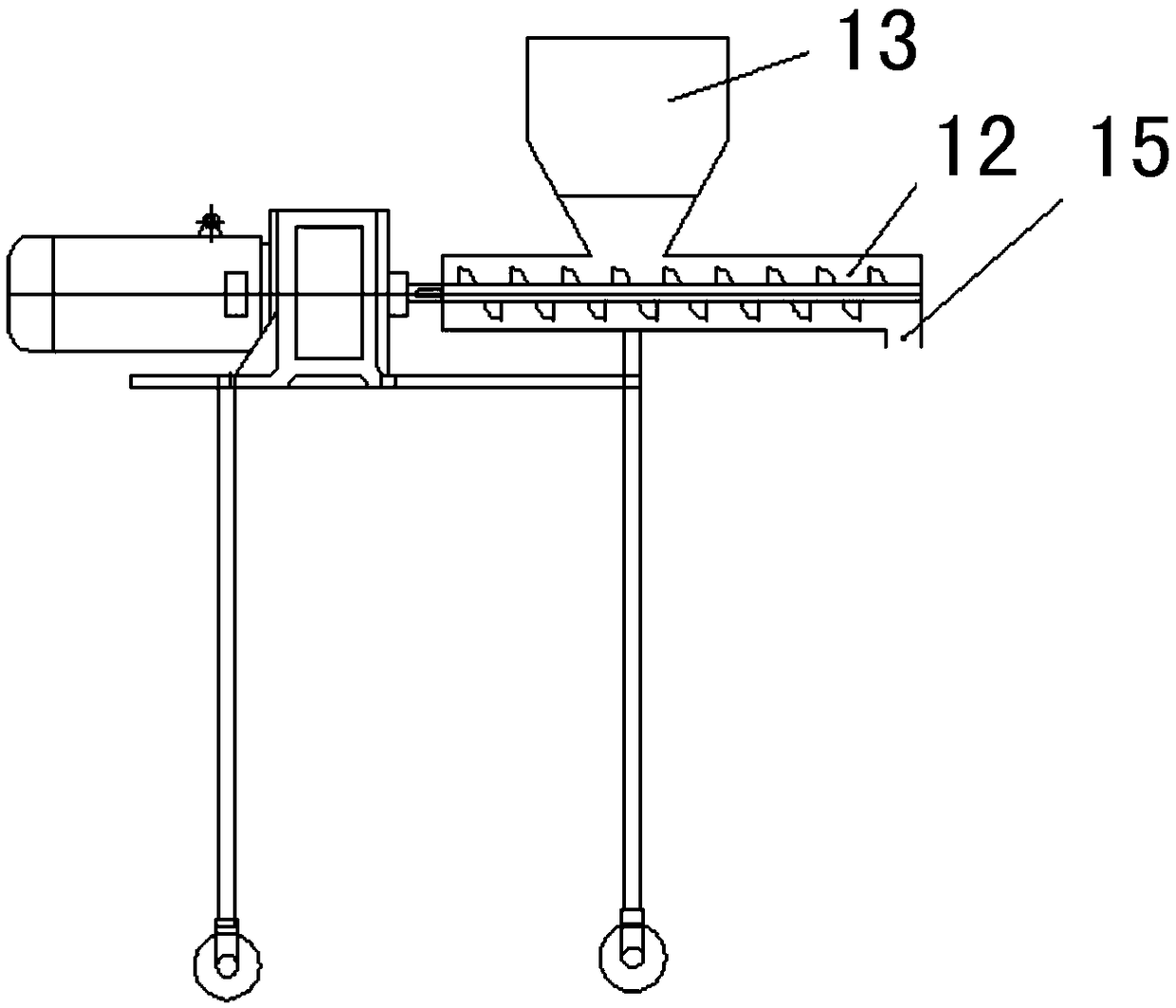

[0042] Cast-in-place polystyrene particle foamed concrete dispersion construction system such as figure 1As shown, it includes primary stirring device, secondary stirring device 17, hose pump 22 and polystyrene particle conveying device arranged on the construction floor site, the primary stirring device is arranged on the ground of the construction floor site, secondary stirring device 17, hose The pump 22 and the polystyrene particle conveying device are arranged on the construction floor;

[0043] The screw pump of the primary stirring device is communicated with the feed inlet of the stirring storage tank 9, and the discharge port of the stirring storage tank 9 is communicated with the slurry inlet of the secondary stirring device 17 through a pipeline with a material pump, and the secondary stirring device 17 The slurry inlet is also communicated with the outlet of the foaming machine 23; the particle feed port of the secondary stirring device 17 is opposite to the partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com