PE packaging bag production process

A production process and packaging bag technology, which is applied in the production process of PE packaging bags, can solve the problems of lack of installation tightness, achieve excellent yield tensile strength and toughness, increase the connection amount, and optimize the production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

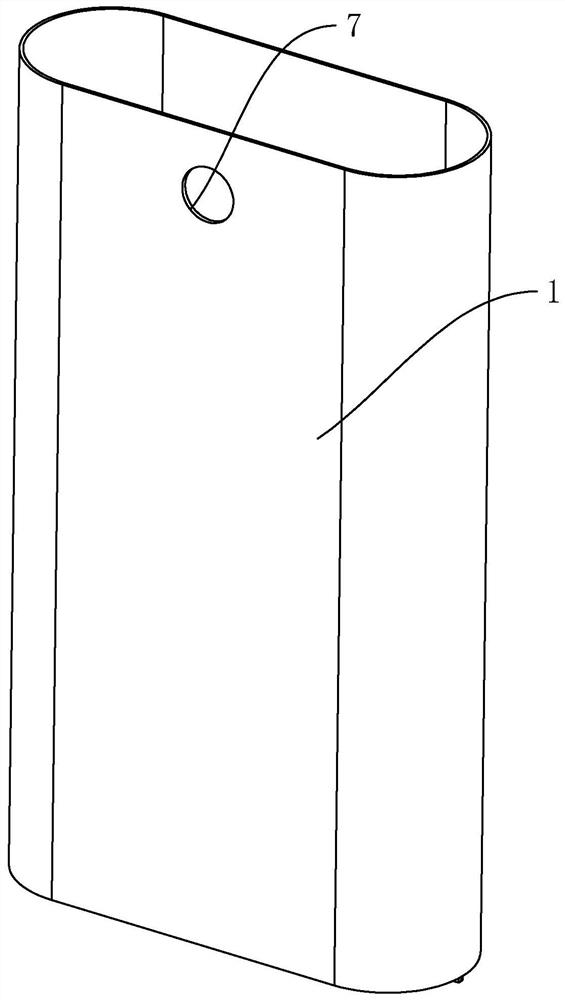

[0050] Embodiment one, the production technology of PE packing bag, comprises the following steps:

[0051] A. Blow molding:

[0052] (1) Raw materials: PE stretch film and modified ingredients;

[0053] (2) Equipment: three-layer plastic co-extrusion blown composite film unit;

[0054] (3) Working process: feeding, setting the reel-shaped PE stretch film on the turret, and adding modified ingredients in the ingredient adding cylinder; debugging, according to the thickness of the required packaging bag and modified ingredients characteristics, adjust the operating parameters of the three-layer plastic co-extrusion blown composite film unit; winding, after the equipment is in normal operation, the processed composite film is rewound;

[0055] (4) Technical effect: A three-layer plastic co-extrusion blown composite film unit is adopted, so that according to actual needs, the inner layer, outer layer or two layers of composite functional layers of PE stretch film can be added a...

Embodiment 2

[0072] Embodiment two, the difference between embodiment two and embodiment one is that the production process of PE packaging bag also includes printing and dyeing:

[0073] (1) Equipment: computer gravure printing machine;

[0074] (2) Raw materials: water-based PE ink, PP treatment agent;

[0075] (3) Workflow: Prepare the printing template according to the pattern to be printed, and prepare the water-based PE ink according to the printing color. After the preliminary preparation is completed, the roll-shaped composite film that has not yet completed the bag making is set on the feeding of the computer gravure printing machine end, then debug and plate-align, then start normal printing, and finally wind up the printed composite film;

[0076] (4) Technical effect: The printing and dyeing steps are set before the bag making, which optimizes the process steps and effectively improves the production efficiency; in the existing technology, the printing and dyeing steps are gen...

Embodiment 3

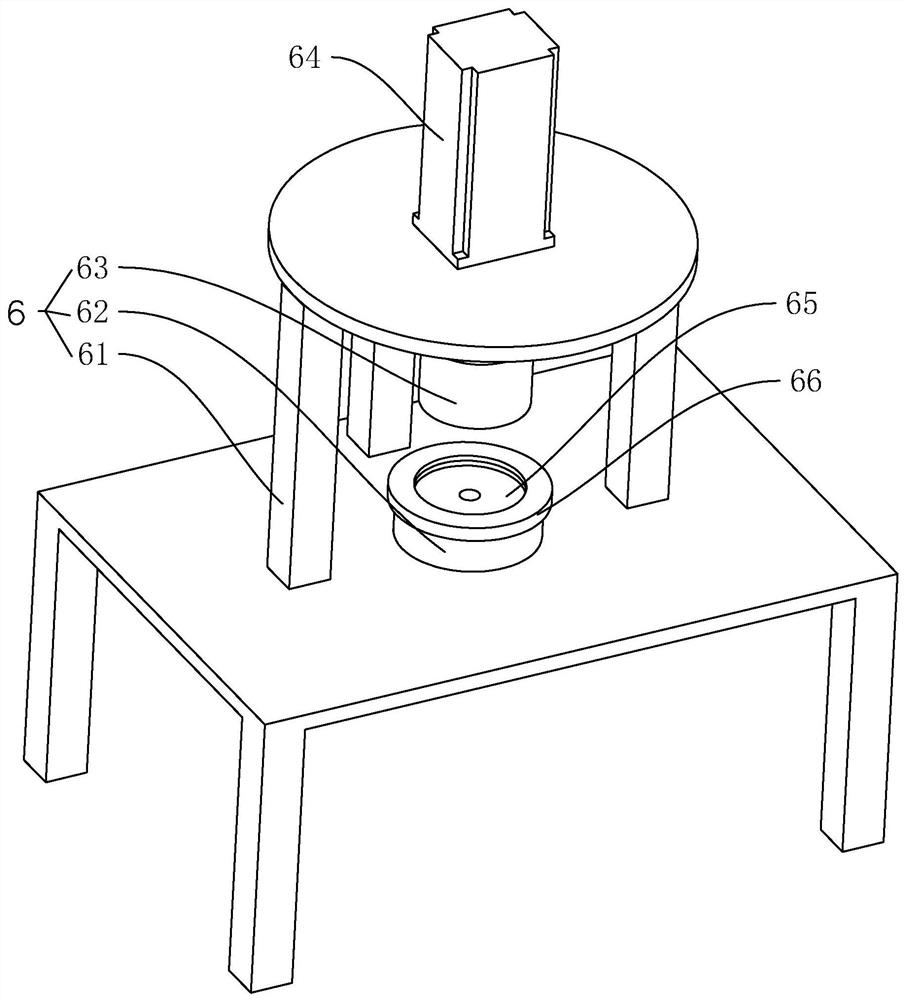

[0077] Embodiment three: the difference between embodiment three and embodiment two is that the production process of the PE packaging bag also includes hemming:

[0078] (1) Equipment: folding machine;

[0079] (2) Work process: Set the roll-shaped composite film that has not yet completed bag making on the feeding end of the folding machine, then debug the folding machine according to the specifications and sizes of the composite film, and run the folding machine normally after debugging, and finally close the Composite film with folded edges;

[0080] (3) Technical effects: such as Figure 4 As shown, there is a fold on both sides of the formed PE packaging bag, so that the unfolded area of the empty PE packaging bag can be effectively reduced without affecting the capacity of the PE packaging bag, thereby facilitating transportation.

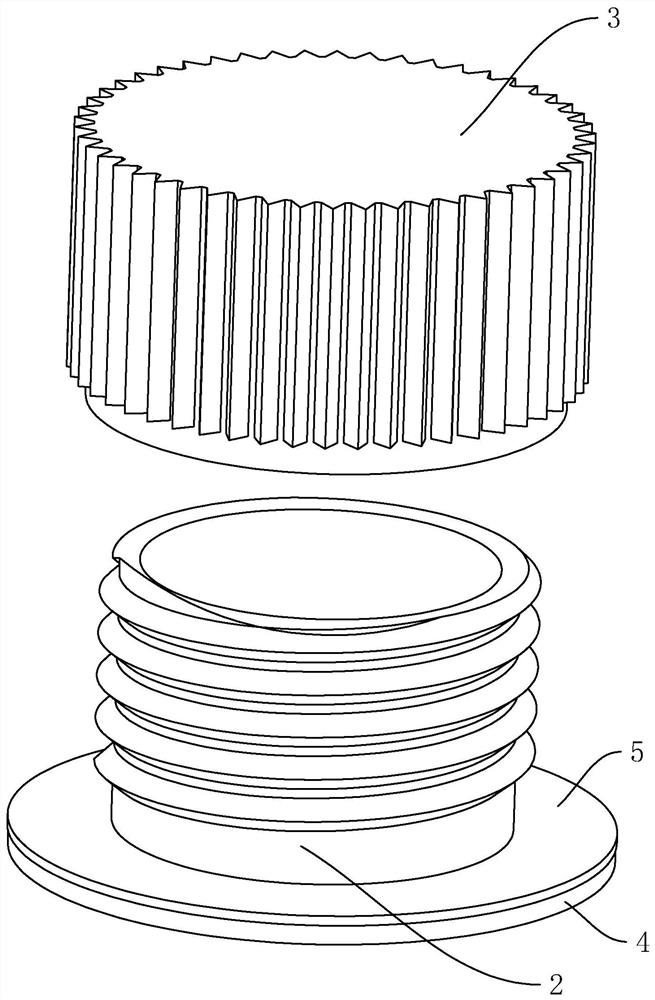

[0081] It should be noted that the production process of PE packaging bags also includes embossing: select the embossing roller accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com