Shallow bottom pit steel belt traction home lift

A technology for household elevators and shallow pits, which is applied to elevators in buildings, hoists, and lifting equipment in mines, etc., which can solve the problem of elevator noise and poor ride comfort, affecting elevator stability and ride comfort Improvement and other issues, to achieve the effect of reducing the workload of later maintenance, reducing labor costs and material costs, and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the examples, but not as a basis for limiting the present invention.

[0025] Example.

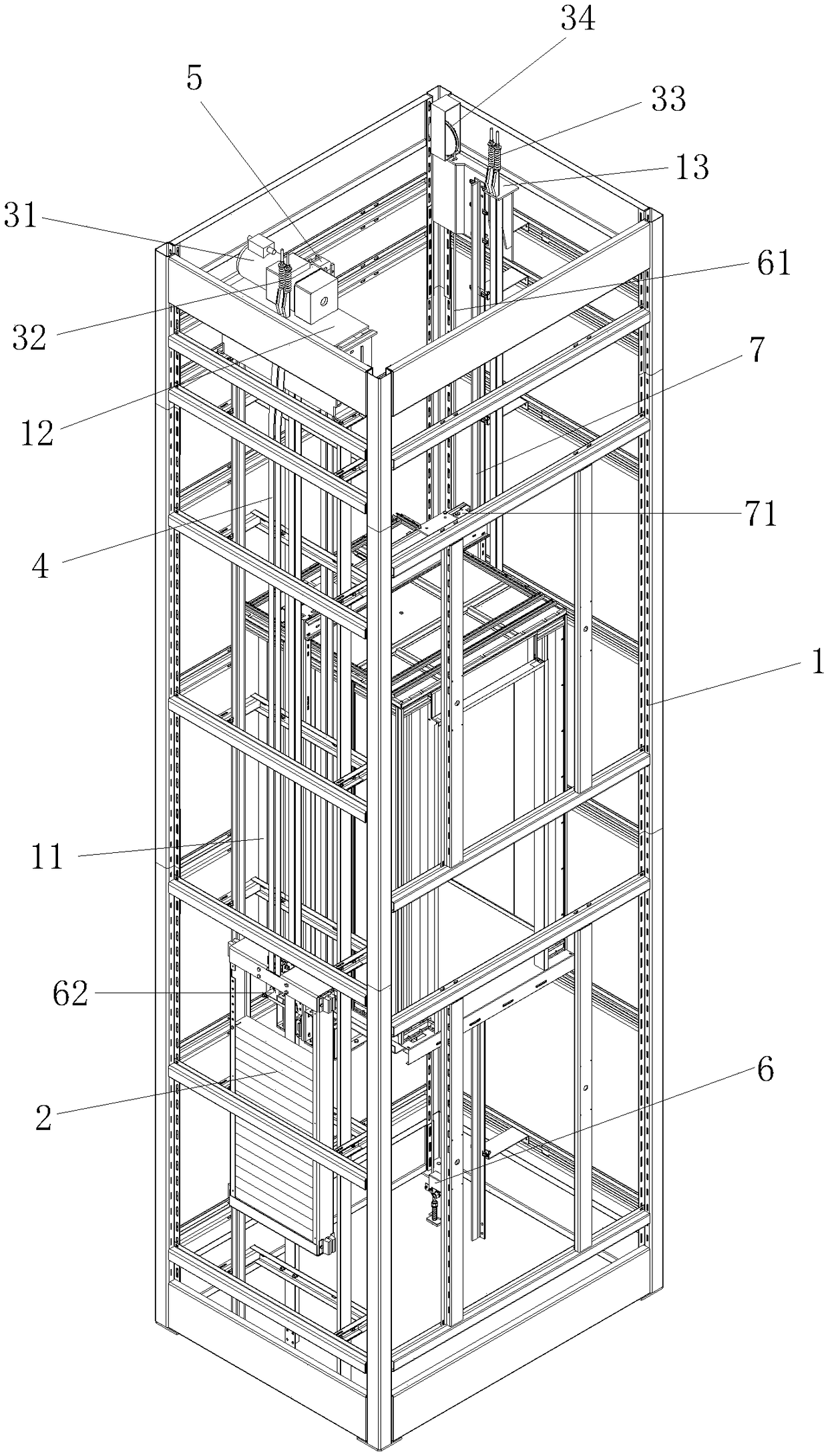

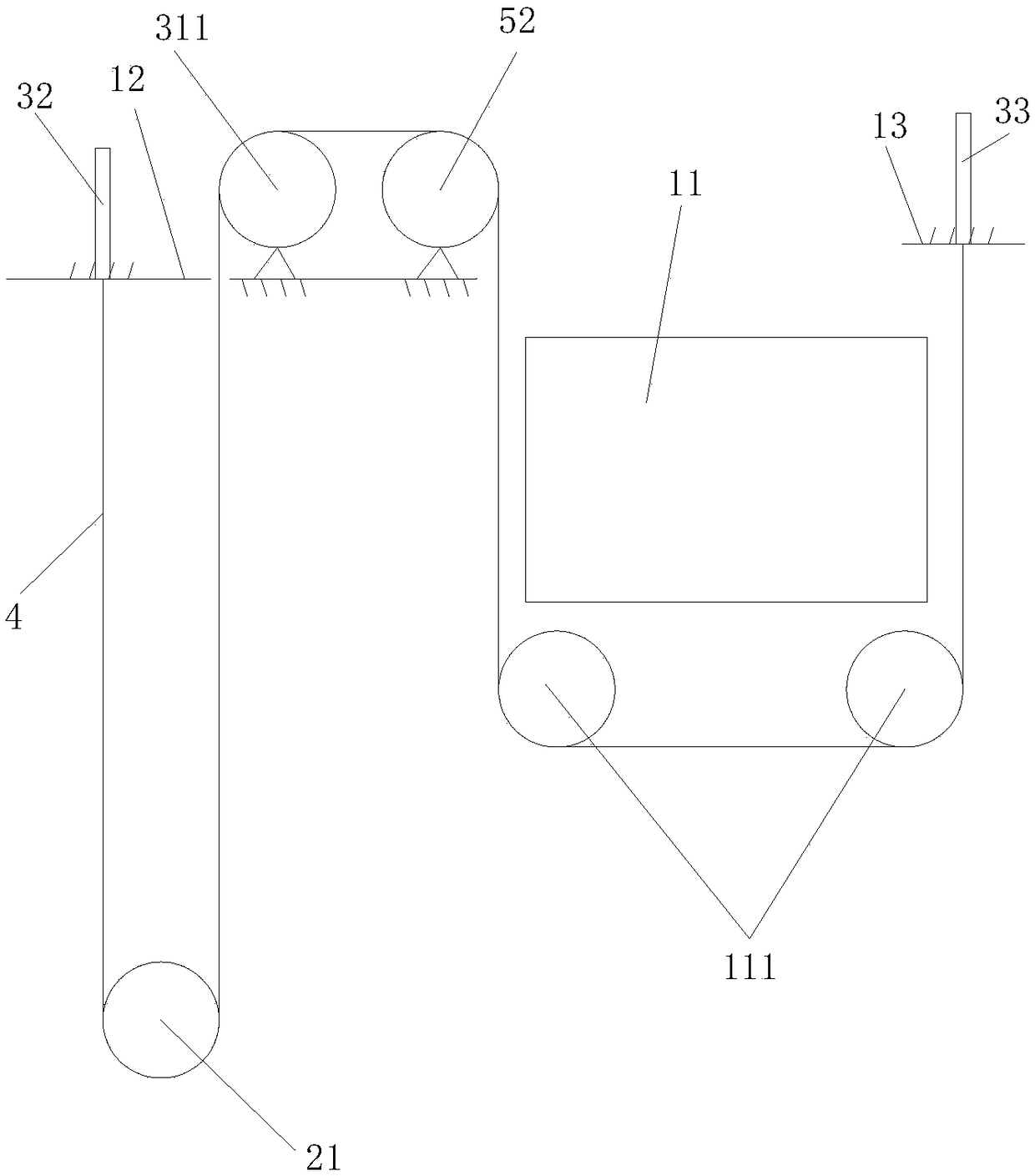

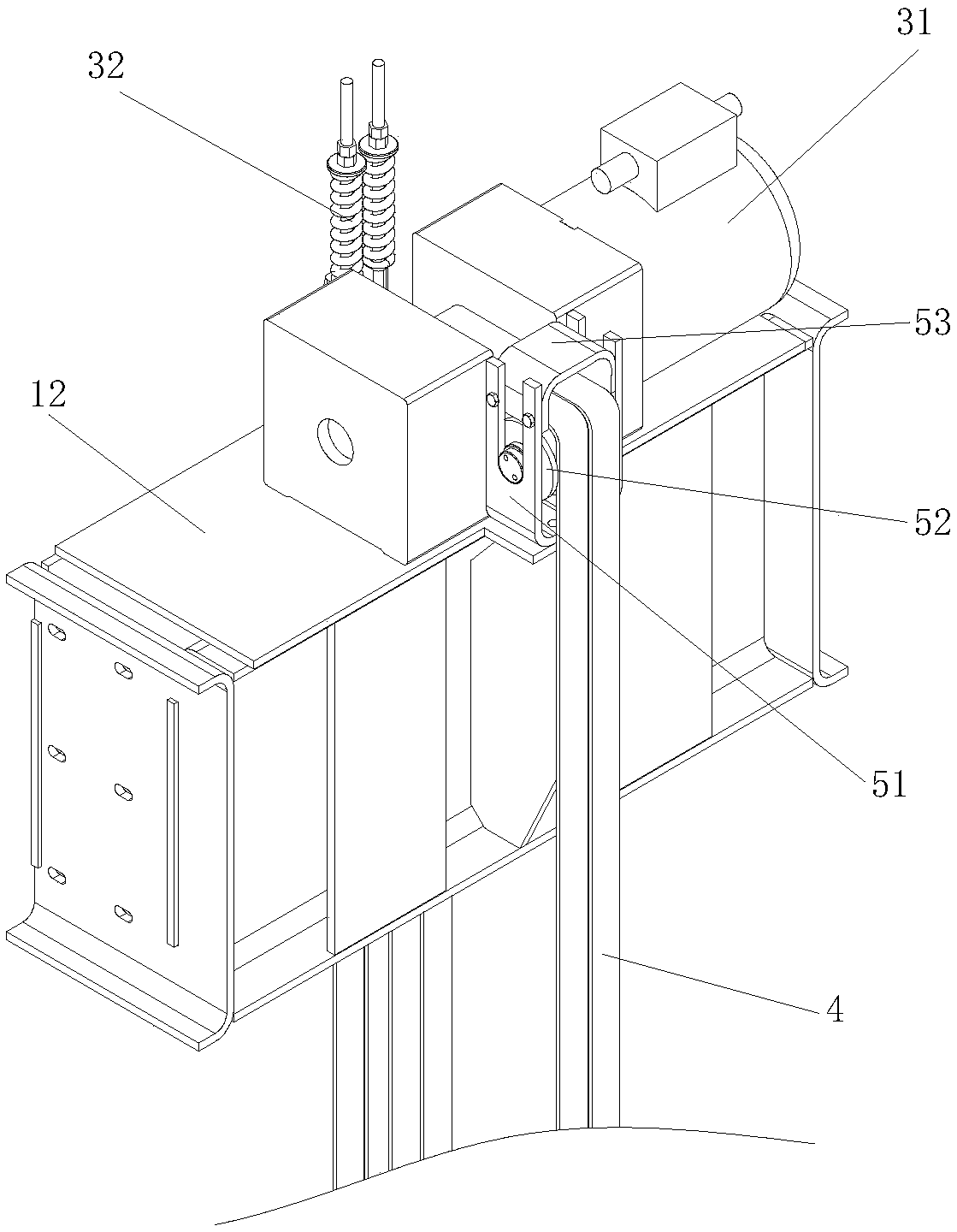

[0026] Such as Figure 1-4 As shown, the shallow pit steel belt traction home elevator includes a steel frame 1, a car 11 and a counterweight device 2 are provided inside the steel frame 1, and first brackets 12 are respectively provided on the inner sides opposite to the top of the steel frame 1. And the second support 13, the first support 12 is provided with the traction machine 31, the first rope end combination 32 and the anti-jump device 5, the second support 13 is provided with the second rope end combination 33, the first rope end combination 32 A steel belt 4 is provided on the top, and the steel belt 4 includes two rows of steel wire rope groups 41 arranged at intervals. The outside of the steel wire rope group 41 is wrapped with an elastic rubber layer 42, and the outside of the elastic rubber laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com