Production method of self-adhesive label for loading blood culture bottle

A production process and blood culture technology, which is applied in the production process of self-adhesive labels, can solve the problems of poor antibacterial effect and difficult peeling of labels, and achieve good antibacterial effect, not easy to grow bacteria, and have little impact on use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention will be further described in detail below in conjunction with specific examples, but the protection scope of the present invention is not limited to the following description.

[0031] A production process for the self-adhesive label of the blood culture bottle on the machine, comprising the following steps:

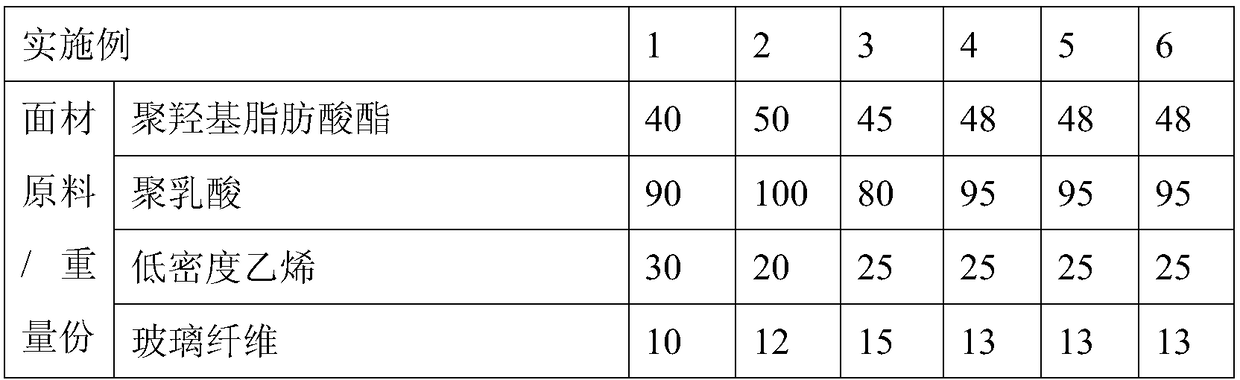

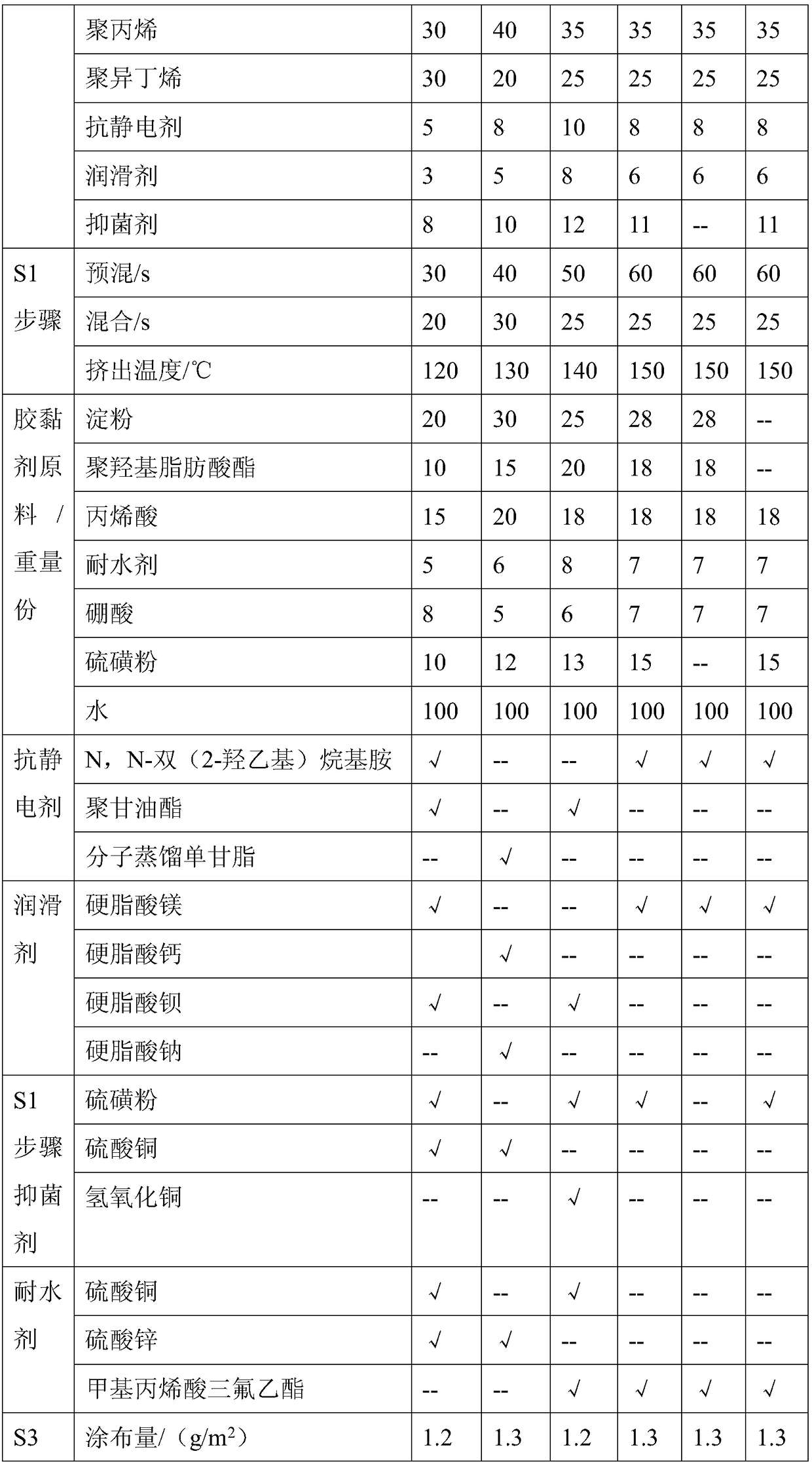

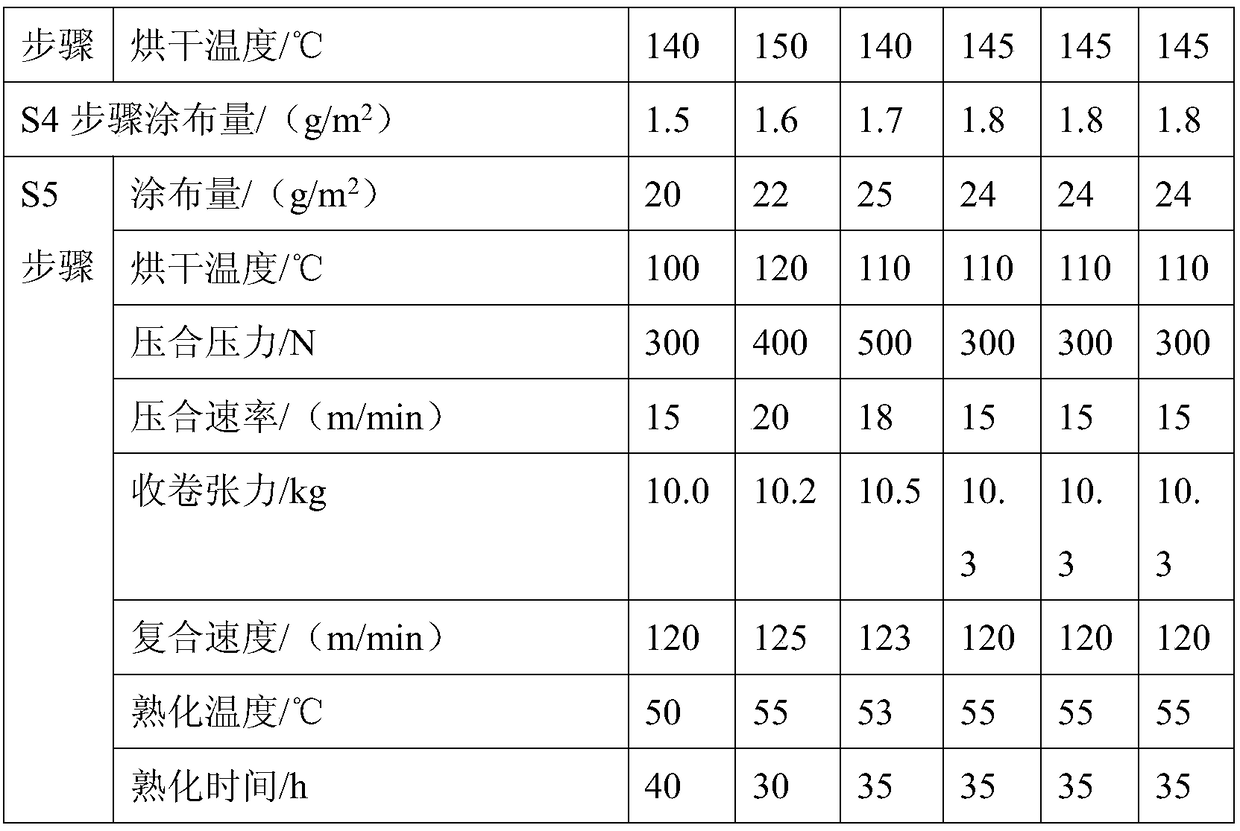

[0032] Preparation of S1 surface material: Prepare raw materials according to parts by weight: 40-50 parts of polyhydroxyalkanoate, 80-100 parts of polylactic acid, 20-30 parts of low-density ethylene, 10-15 parts of glass fiber, 30-40 parts of polypropylene , 20-30 parts of polyisobutylene, 5-10 parts of antistatic agent, 3-8 parts of lubricant, 8-12 parts of antibacterial agent, polyhydroxyalkanoate, polylactic acid, low-density ethylene, glass fiber, polypropylene Add polyisobutylene and polyisobutylene into a high-speed pulverizer for pre-mixing for 30-60s, then add antistatic agent, lubricant and antibacterial a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com