Method for producing oil-tea camellia seed oil

A technology of Camellia oleifera seed oil and production method, which is applied in the direction of fat oil/fat production, fat production, fat oil/fat refining, etc., can solve the problems of high cost of enzyme use, easy emulsification, etc., to reduce oil absorption rate, disperse pigment, and lower temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

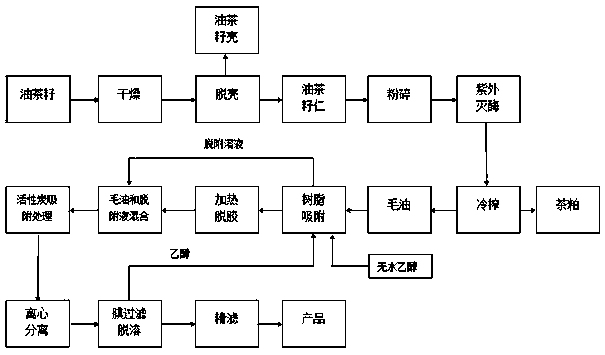

Image

Examples

Embodiment 1

[0029] A kind of production method of camellia oleifera seed oil, it comprises the following steps:

[0030] (1) Drying and shelling: The camellia oleifera fruit is dried in the sun or at low temperature. The drying temperature is lower than 70°C. After the water content of the camellia oleifera fruit is dried to 10%, it is shelled by a sheller. 12%;

[0031] (2) Crush ultraviolet light to inactivate enzymes: Crush camellia seed kernels to 15 meshes and irradiate for 6 minutes under ultraviolet rays with a power of 150w;

[0032] (3) Cold pressing: putting the Camellia oleifera seed kernels irradiated by ultraviolet rays into the press, and pressing the oil at 25°C to obtain cold-pressed crude oil;

[0033] (4) Resin adsorption: Adsorb squalene, vitamin E and β-carotene in crude oil through X-5 macroporous resin, and use absolute ethanol to desorb squalene, vitamin E and β-carotene. Desorption;

[0034] (5) Heating degumming: Add 5% crude oil weight pure water to the crude ...

Embodiment 2

[0039] A kind of production method of camellia oleifera seed oil, it comprises the following steps:

[0040] (1) Drying and shelling: The camellia oleifera fruit is dried in the sun or at low temperature. The drying temperature is lower than 70°C. After the water content of the camellia oleifera fruit is dried to 10.5%, it is shelled by a sheller. 11%;

[0041] (2) Crush ultraviolet light to inactivate enzymes: crush camellia seed kernels to 20 mesh, and irradiate for 5 minutes under ultraviolet light with a power of 150w;

[0042] (3) Cold pressing: putting the Camellia oleifera seed kernels irradiated by ultraviolet rays into the press, and pressing the oil at 30°C to obtain cold-pressed crude oil;

[0043] (4) Resin adsorption: Adsorb squalene, vitamin E and β-carotene in crude oil through X-5 macroporous resin, and use absolute ethanol to desorb squalene, vitamin E and β-carotene. Desorption;

[0044](5) Heating degumming: add 5% crude oil weight pure water to the crude...

Embodiment 3

[0049] A kind of production method of camellia oleifera seed oil, it comprises the following steps:

[0050] (1) Drying and shelling: The camellia oleifera fruit is dried in the sun or at low temperature. The drying temperature is lower than 70°C. After the water content of the camellia oleifera fruit is dried to 11%, it is shelled by a sheller. 12%;

[0051] (2) Crush ultraviolet light to inactivate enzymes: Crush camellia seed kernels to 20 mesh and irradiate for 8 minutes under ultraviolet light with a power of 150w;

[0052] (3) Cold pressing: putting the Camellia oleifera seed kernels irradiated by ultraviolet rays into the press, and pressing the oil at 25°C to obtain cold-pressed crude oil;

[0053] (4) Resin adsorption: Adsorb squalene, vitamin E and β-carotene in crude oil through X-5 macroporous resin, and use absolute ethanol to desorb squalene, vitamin E and β-carotene. Desorption;

[0054] (5) Heating degumming: add 5% crude oil weight pure water to the crude o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com