A multi-stage tea oil filtration tank

A filter tank and camellia oil technology, which is applied in filtration separation, fixed filter element filter, fat oil/fat refining, etc. It can solve the problems such as difficult discharge of filter residue, slow filtration of tea oil, and the quality of tea oil cannot meet people's needs, etc., to achieve The effect of improving safety and reliability, increasing passing speed and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation of the invention will be further described below in conjunction with the accompanying drawings.

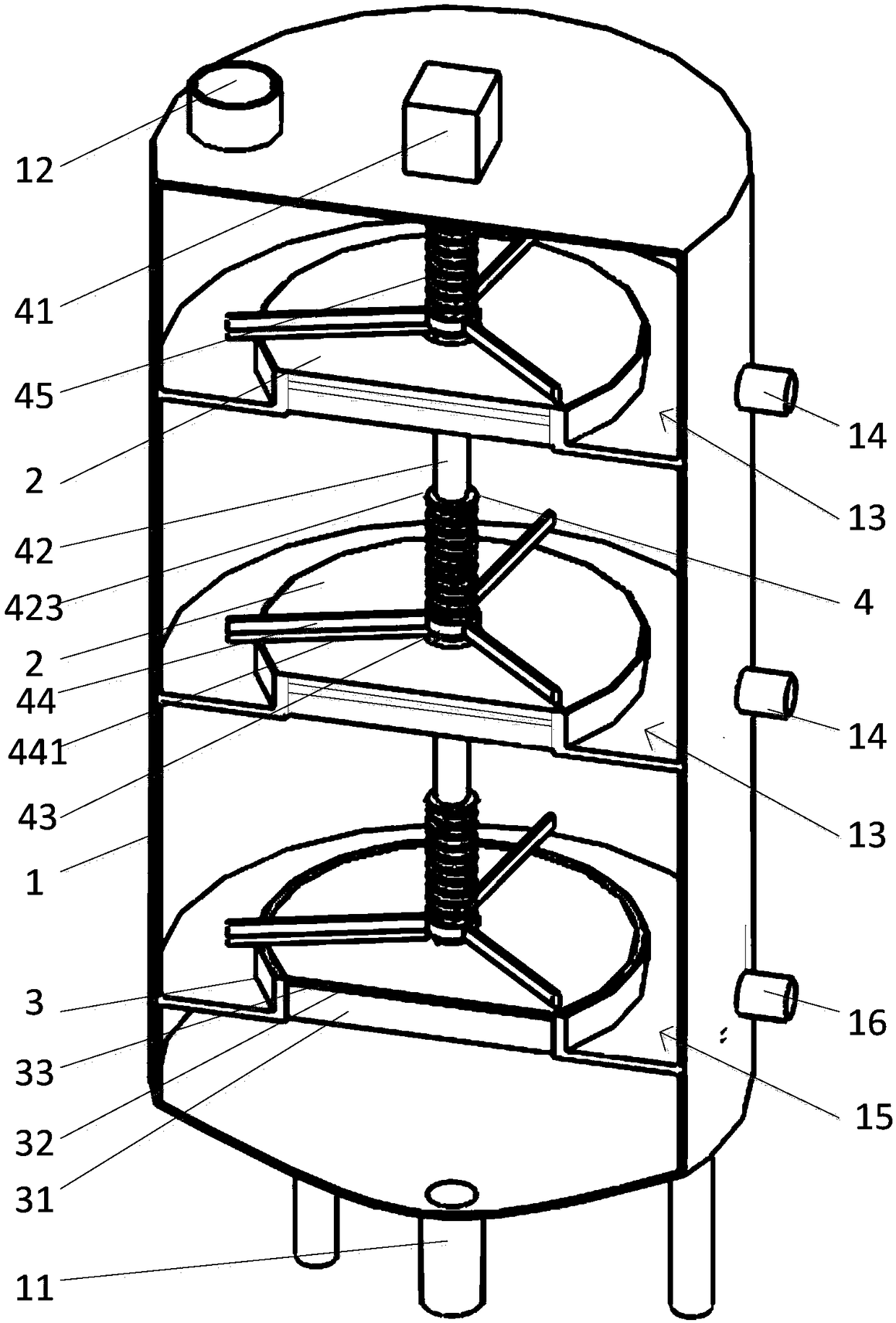

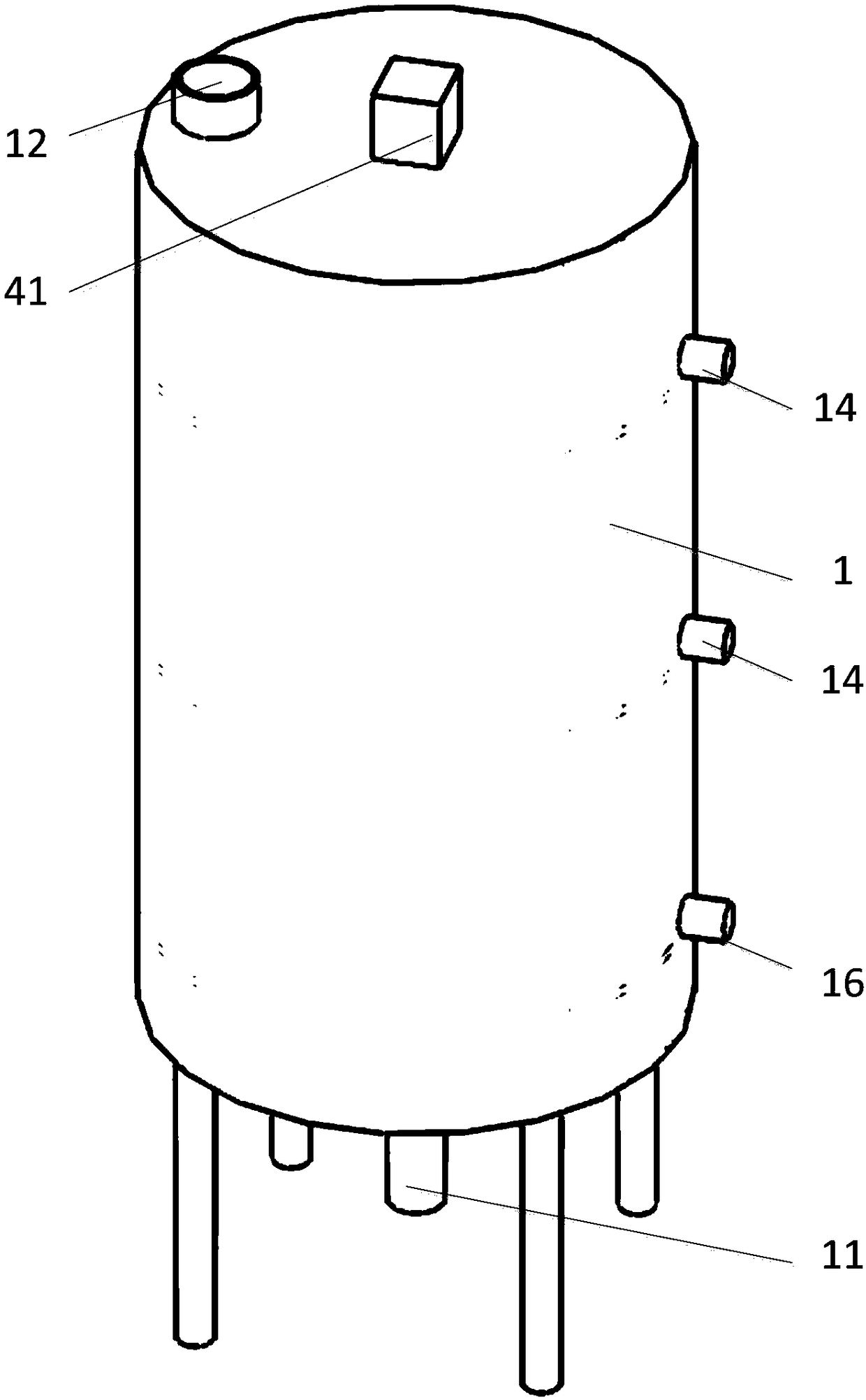

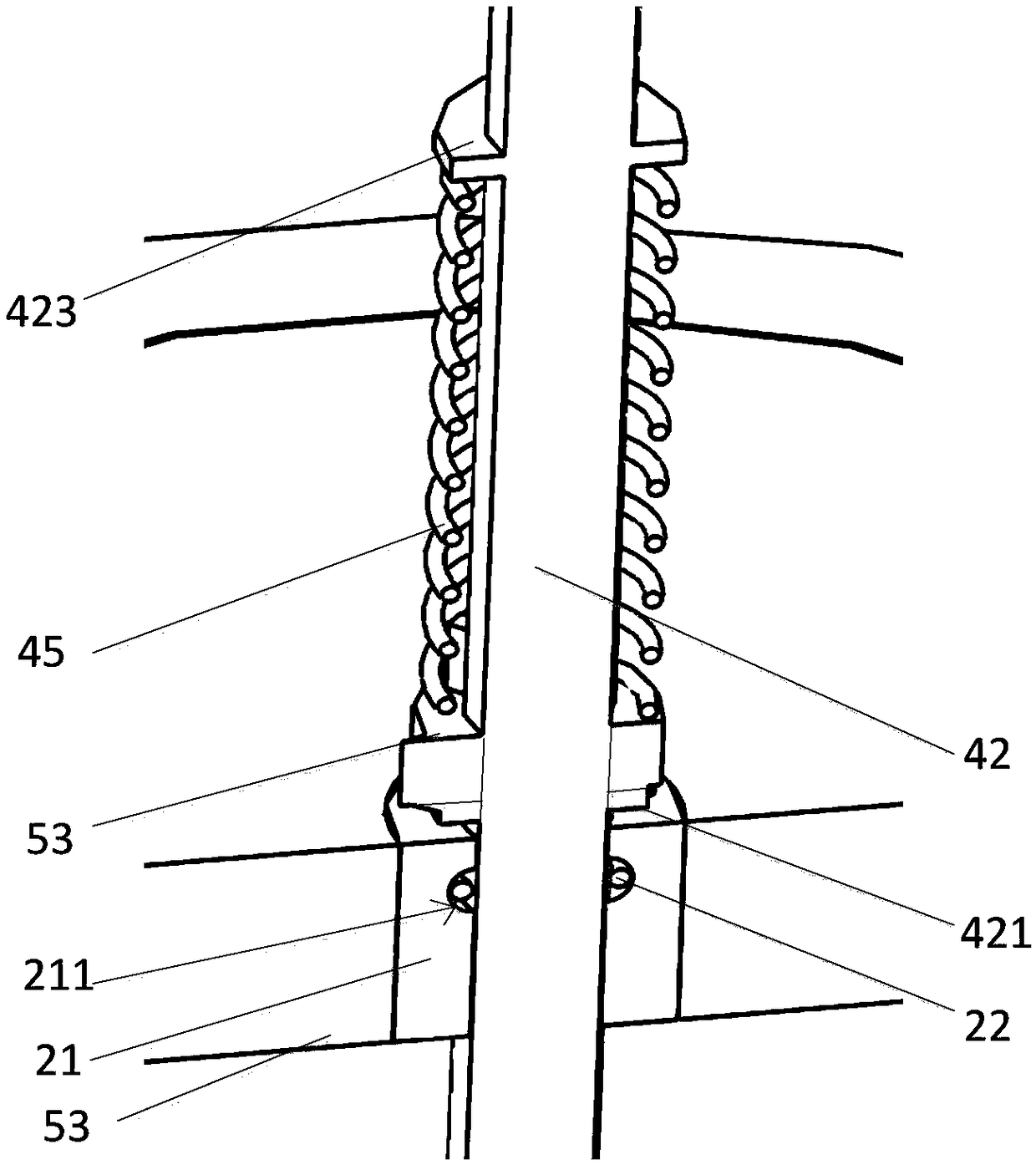

[0027] like figure 1 and figure 2 Shown, a kind of camellia oil multistage filter tank is characterized in that: comprise tank body 1, two first filter layers 2, the second filter layer 3 and net scraping device 4; Wherein:

[0028] The upper part of the tank body 1 is cylindrical, the lower part of the tank body 1 is inverted conical, the lower end of the tank body 1 is provided with an oil outlet 11, and the upper part of the tank body 1 is provided with an oil inlet port 12;

[0029] The two first filter layers 2 are arranged in the upper part of the tank body 1, and the two first filter layers 2 are parallel to each other; the first filter layer 2 has a circular boss structure, and the outer wall of the circular boss structure of the first filter layer 1 A first filter residue tank 13 is formed between the inner wall of the tank body 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com