Air-quenching water-cooling granulation method of lead matte

A technology of lead matte and air quenching, which is applied in the granulation field of lead matte air quenching and water cooling, which can solve the problems of difficult crushing and fine grinding of materials, difficult granulation of lead matte slag, and high hardness, so as to avoid explosion blasting, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

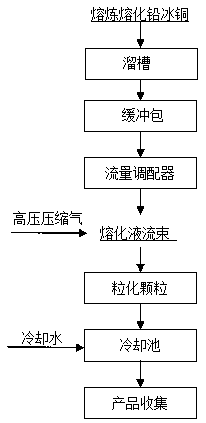

[0027] Such as figure 1 Shown, a kind of lead matte air-quenching water cooling granulation method of the present invention comprises the following steps:

[0028] 1) The side of the melting furnace is provided with a round hole for the outflow of liquid and a closed switch matching the round hole (in the embodiment of the present invention, the diameter of the round hole is set to 20mm), and the side of the melting furnace is connected with the chute and the middle through the round hole in turn. The bag channel is connected with the flow regulator; the round hole on the side of the melting furnace is blocked;

[0029] After the lead matte is melted in a smelting furnace (the melting temperature is controlled at 1050-1150°C to form a lead matte high-temperature molten liquid), the closed switch of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com