Preparation method for transparent elastic fish screen shoe cloth and products and application of transparent elastic fish screen shoe cloth

A technology of elastic fish and fish shreds, which is applied in the field of shoe fabrics, can solve the problems that it is difficult to meet the needs of beauty and individuality, the ventilation effect is not very ideal, and it is easy to delaminate or fall off, etc., so as to shorten the production cycle and achieve novel appearance and good quality. elastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

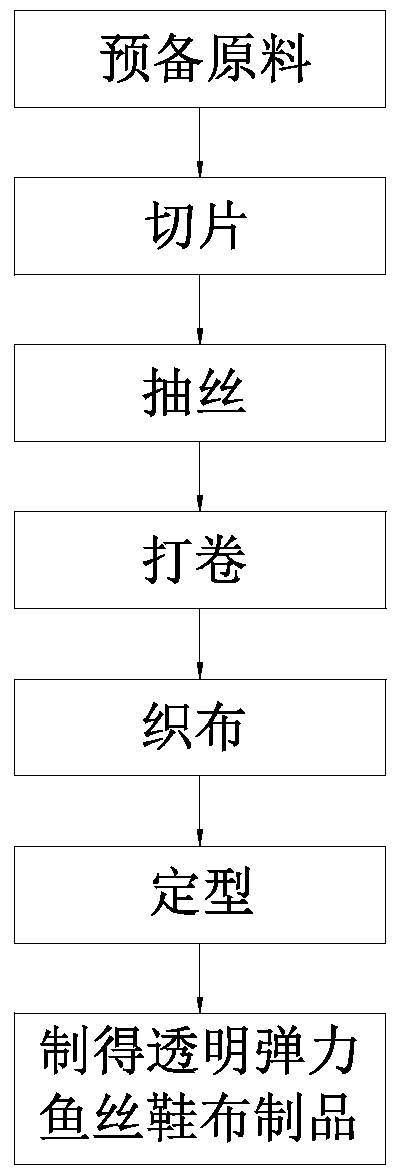

[0031] Example 1: see figure 1 , a kind of preparation method of transparent elastic fish silk shoe cloth provided by the present embodiment, it comprises the following steps:

[0032] (1) Prepare raw materials: prepare polyester blocks, spandex blocks and TPU blocks;

[0033] (2) Slicing: Slicing polyester blocks, spandex blocks and TPU blocks to produce polyester sheets, spandex sheets and TPU sheets;

[0034] (3) Spinning: Add polyester flakes, spandex flakes and TPU flakes into the extruder, and when they are put into the hopper of the extruder, the mass percentage of the polyester flakes, spandex flakes and TPU flakes For: 5% polyester flakes, 5% spandex flakes, 90% TPU flakes. Melting, extruding and spinning are carried out through an extruder, and the extrusion and spinning speed of the extruder is preferably 5-15 m / min, which can be selected according to the fineness of the spinning. The fineness of the elastic fish shreds is preferably 75-150D, and the smaller the ...

Embodiment 2

[0042]Embodiment 2: A kind of preparation method of transparent elastic fish silk shoe cloth provided by this embodiment, it comprises the following steps:

[0043] (1) Preparing raw materials: preparing polyester blocks, spandex blocks and TPU blocks; (2) Slicing: slicing polyester blocks, spandex blocks and TPU blocks to obtain polyester sheets, spandex sheets and TPU Sheets; (3) Spinning: Add polyester flakes, spandex flakes and TPU flakes into the extruder, and when they are put into the hopper of the extruder, the polyester flakes, spandex flakes and TPU flakes The mass percentages are: 10% polyester flakes, 10% spandex flakes, and 80% TPU flakes. After spinning, the elastic fish shreds are obtained; (4) Rolling: the elastic fish shreds are wound on the wire reel at an even speed to obtain the elastic fish shreds reel; (5) Weaving: the elastic fish shreds reel is installed on the On the upper line mechanism of the knitting machine, the thread is fed by the upper line mec...

Embodiment 3

[0046] Embodiment 3: A kind of preparation method of transparent elastic fish silk shoe cloth provided by this embodiment, it comprises the following steps:

[0047] (1) Preparing raw materials: preparing polyester blocks, spandex blocks and TPU blocks; (2) Slicing: slicing polyester blocks, spandex blocks and TPU blocks to obtain polyester sheets, spandex sheets and TPU Sheets; (3) Spinning: Add polyester flakes, spandex flakes and TPU flakes into the extruder, and when they are put into the hopper of the extruder, the polyester flakes, spandex flakes and TPU flakes The mass percentages are: polyester flakes 15%, spandex flakes 15%, TPU flakes 70%. After spinning, the elastic fish shreds are obtained; (4) Rolling: the elastic fish shreds are wound on the wire reel at an even speed to obtain the elastic fish shreds reel; (5) Weaving: the elastic fish shreds reel is installed on the On the upper line mechanism of the knitting machine, the thread is fed by the upper line mechan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com