Inlet valve and washing machine integrated with heating function

A water inlet valve and washing machine technology, which is applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of wasting water resources, occupying a large space, and heating time, etc., and achieves easy installation and disassembly, convenient assembly and The effect of maintenance and increase of occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

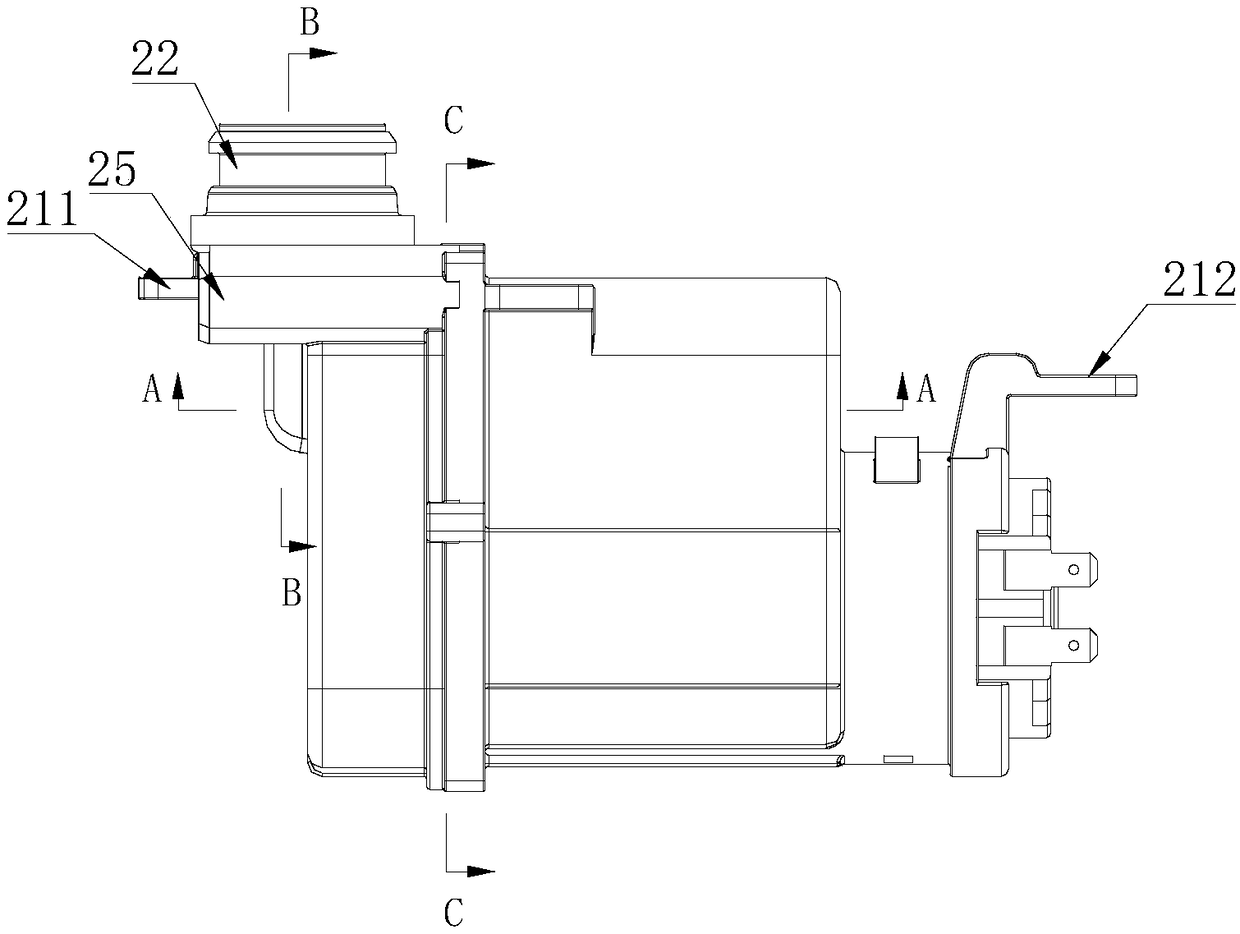

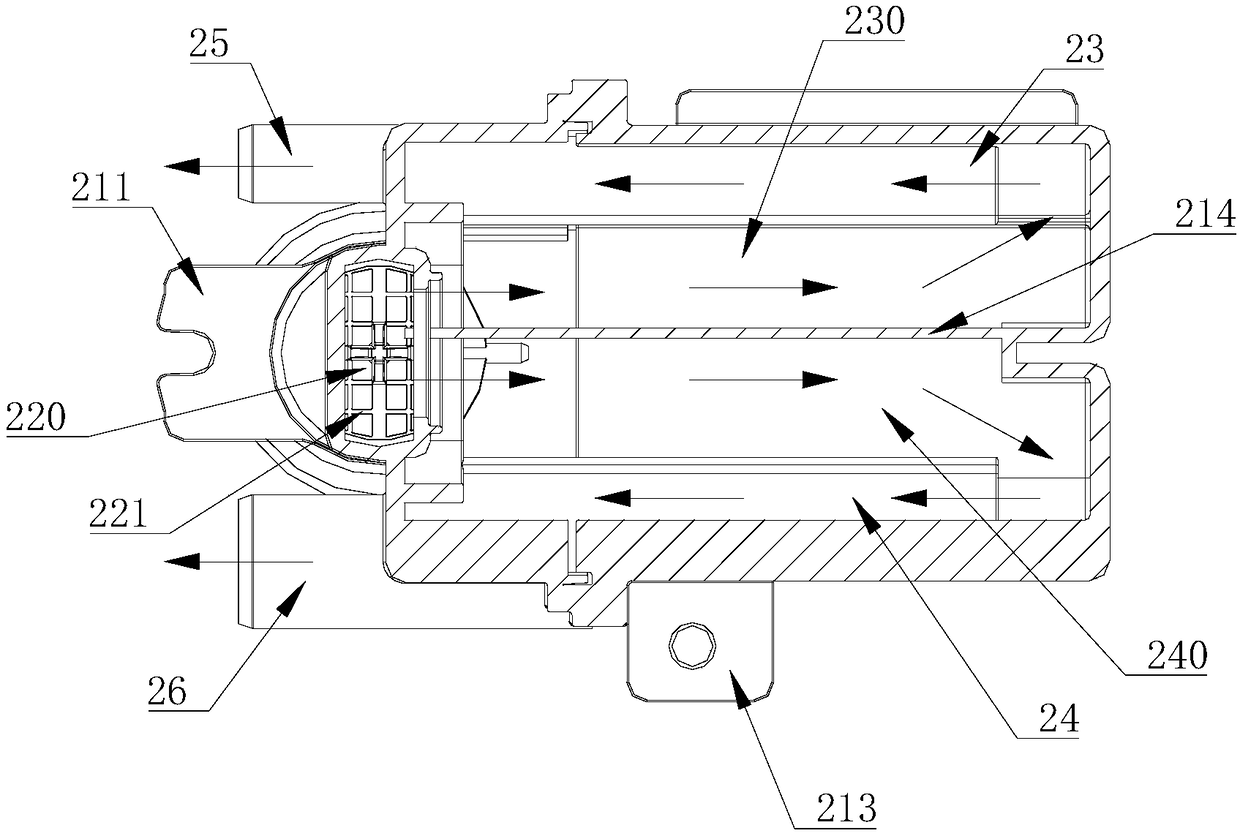

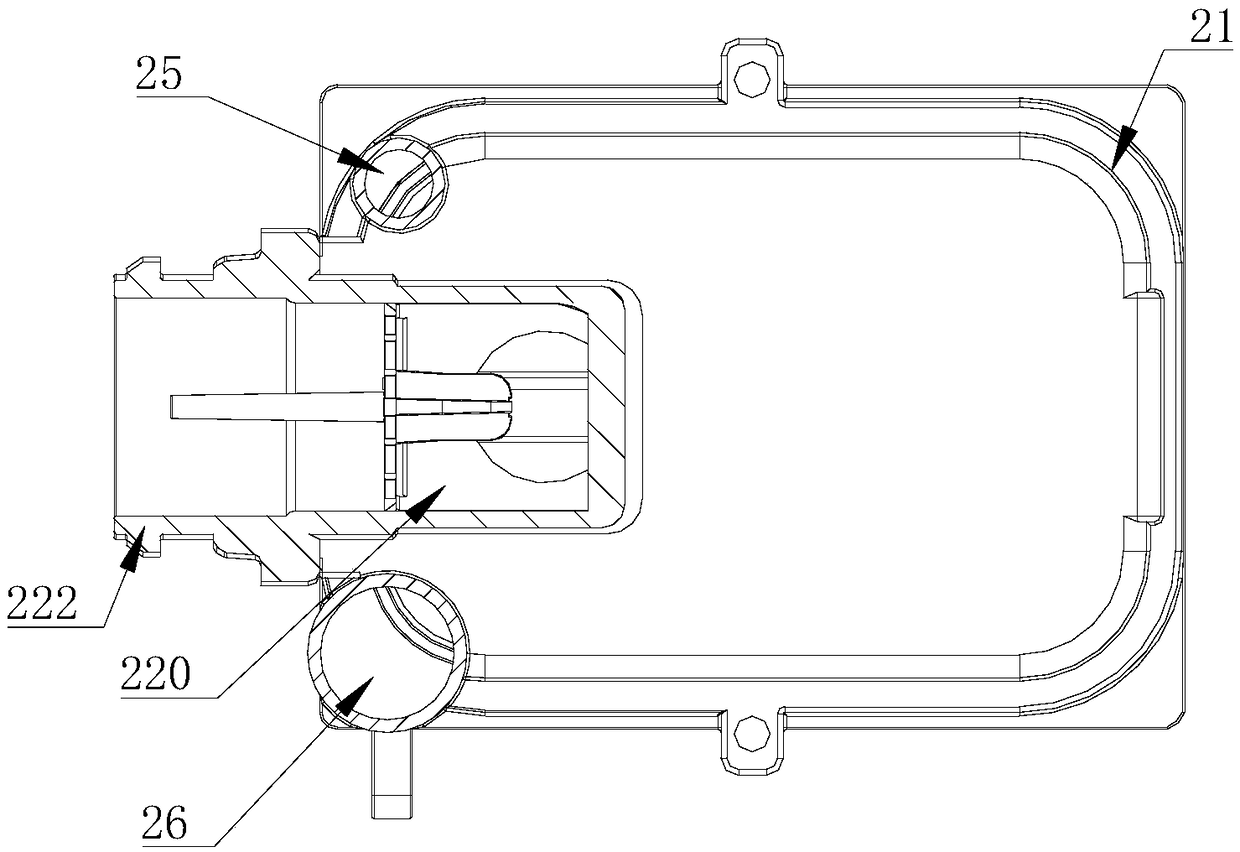

[0048] Such as Figures 1 to 4 As shown, in the water inlet valve 2 integrated with the heating function described in this embodiment, the housing 21 is provided with a flow channel connecting the water inlet 22 and the water outlet, and the flow channel is provided with a heating unit 27 for convection. The water flow in the flow channel is heated to realize the purpose of heating the washing water in the tub, and improve the solubility of the detergent and the cleaning ratio of the clothes.

[0049] In this embodiment, the water inlet valve 2 is provided with a valve body part, which can automatically control the on-off of the flow channel. The housing 21 is provided with a first flow channel 23 and a second flow channel 24 which are independent of each other. The first flow channel 23 and the second flow channel The water inlet end of the second flow channel 24 is adjacently arranged and communicated with the water inlet 22 of the water inlet valve 2, and the valve body par...

Embodiment 2

[0062] Such as Figures 5 to 6 As shown, the water inlet valve 2 described in this embodiment is installed on the control panel base 1, and the control panel base 1 is provided with an opening 13 corresponding to the opening of the bucket for users to put in clothes. The delivery wall 12 whose outer periphery gradually shrinks downward, the peripheral wall 11 is arranged around the control panel base 1, and a circle of grooves 14 with a closed top and an open bottom is formed between the outer peripheral wall 11 and the delivery wall 12. The water inlet valve 2 is installed in the groove 14.

[0063] In this embodiment, the water inlet valve 2 is detachably arranged on the control panel base 1, and the control panel base 1 is provided with a discharge port 13, and the outer periphery of the discharge port 13 is a discharge wall that gradually shrinks downward. 12. An outer peripheral wall 11 is arranged around the control panel base 1, and a groove 14 with a closed top and an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com