A kind of preparation method of environment-friendly high-stripping polyurethane/foam composite football leather

A polyurethane and high-peeling technology, which is applied in coatings, textiles and papermaking, etc., can solve the problems of low surface energy of polyolefin foam, poor bonding performance, and affecting the curing degree and strength of the adhesive layer resin.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of environmental protection high stripping polyurethane / foam composite football leather in the present embodiment is as follows:

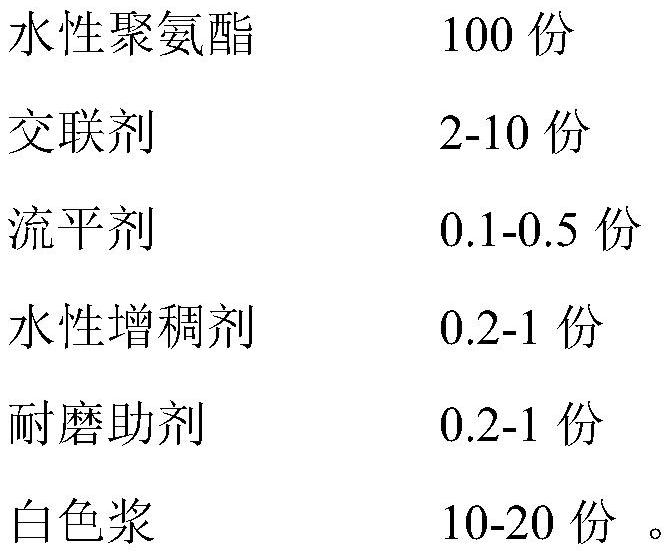

[0036] 1. Water-based polyurethane surface layer slurry consists of 100 parts DL-2611, 2 parts of cross-linking agent XP-2547, 0.1 part of leveling agent Silok-9666, 0.2 part of water-based thickener RM-12W, 0.6 part of wear-resistant additive DC-51 and 10 parts of white paste, scrape it on the release paper, The gap between the covering cutter head is 20 wires, and it is heated and dried at 140°C to obtain the surface layer of polyurethane synthetic leather;

[0037] 2. The slurry for the closed aliphatic polyurethane intermediate layer is composed of 100 parts of FLY-50, 5 parts of isophorone diamine and 10 parts of white paste, which is scraped on the surface layer with a gap of 20 wires between the coating blades , heated and dried at 140°C to obtain the middle layer of polyurethane synthetic leather;

[0038]...

Embodiment 2

[0041] The preparation method of environmental protection high stripping polyurethane / foam composite football leather in the present embodiment is as follows:

[0042] 1. Water-based polyurethane surface layer slurry consists of 100 parts DLV / 1, 6 parts of crosslinking agent XP-2487 / 1, 0.5 parts of leveling agent Silok-354, 1 part of water-based thickener RM-12W, 0.2 parts of wear-resistant additive DC-51 and 20 parts of white paste, scrape on the release paper, coat The gap between the covering cutter head is 25 wires, and it is heated and dried at 120°C to obtain the surface layer of polyurethane synthetic leather;

[0043] 2. The closed aliphatic polyurethane intermediate layer slurry is composed of 100 parts of FLY-50, 10 parts of 4,4'-diaminodicyclohexylmethane and 20 parts of white slurry, which is scraped on the surface layer and coated with a knife The gap between the heads is 25 wires, and it is heated and dried at 130°C to obtain the middle layer of polyurethane ...

Embodiment 3

[0047]The preparation method of environmental protection high stripping polyurethane / foam composite football leather in the present embodiment is as follows:

[0048] 1. Water-based polyurethane surface layer slurry consists of 100 parts DL-2611, 10 parts of crosslinking agent XP-2547, 0.3 parts of leveling agent Silok-8000, 0.6 parts of water-based thickener RM-12W, 1 part of wear-resistant additive DC-51 and 15 parts of white paste, scraped on the release paper, coated with a knife The gap between the heads is 20 wires, and it is heated and dried at 100°C to obtain the surface layer of polyurethane synthetic leather;

[0049] 2. The slurry for the closed aliphatic polyurethane intermediate layer is composed of 100 parts of FLY-50, 7 parts of m-xylylenediamine and 15 parts of white slurry, which is scraped on the surface layer with a gap of 20 wires between the coating blades. Heat and dry at 150°C to obtain the middle layer of polyurethane synthetic leather;

[0050] 3....

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| stretching rate | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com