Method for designing compact water-stabilized crushed stone subbase and its mixture ratio at one time

A water-stabilized crushed stone and compact technology, applied in roads, road repairs, roads, etc., can solve the problem of broken stones, cannot judge the gradation and compactness of synthetic mineral materials well, and does not give the ratio design water stability The judging method of crushed stone mixture and other issues can achieve the effect of improving comprehensive performance, facilitating engineering material preparation, and reducing test investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

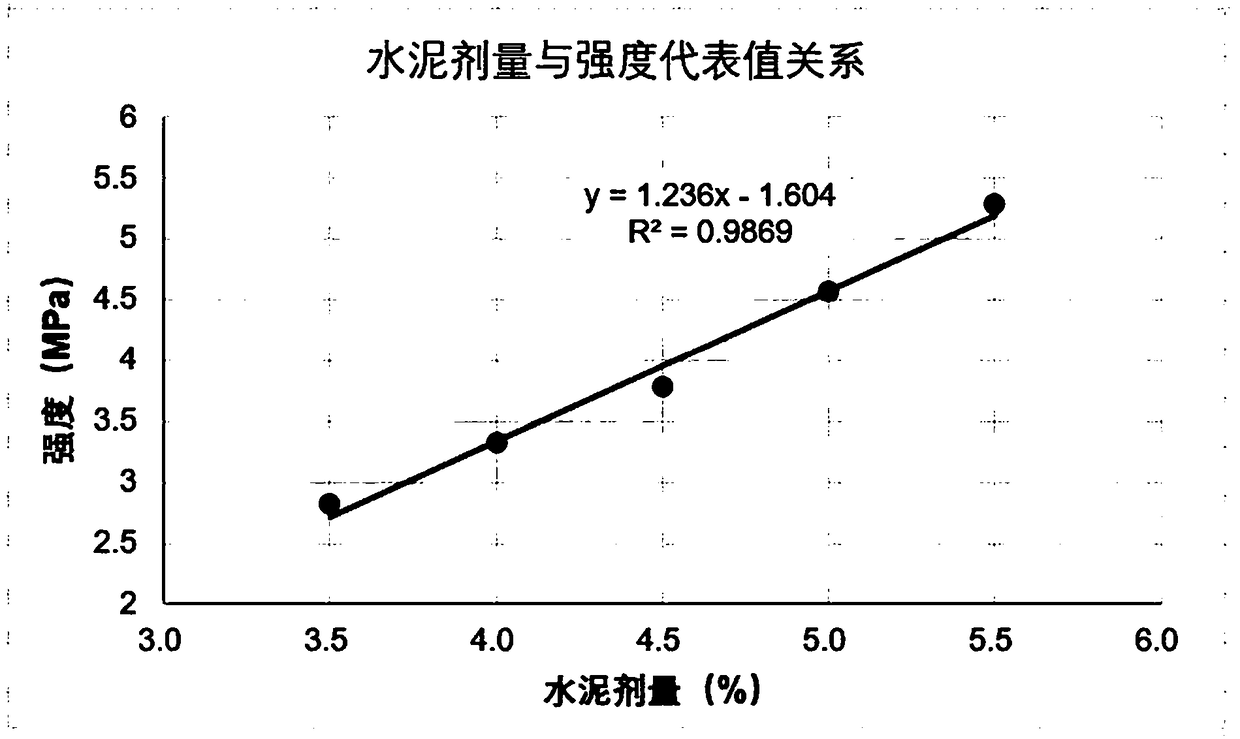

Embodiment 1

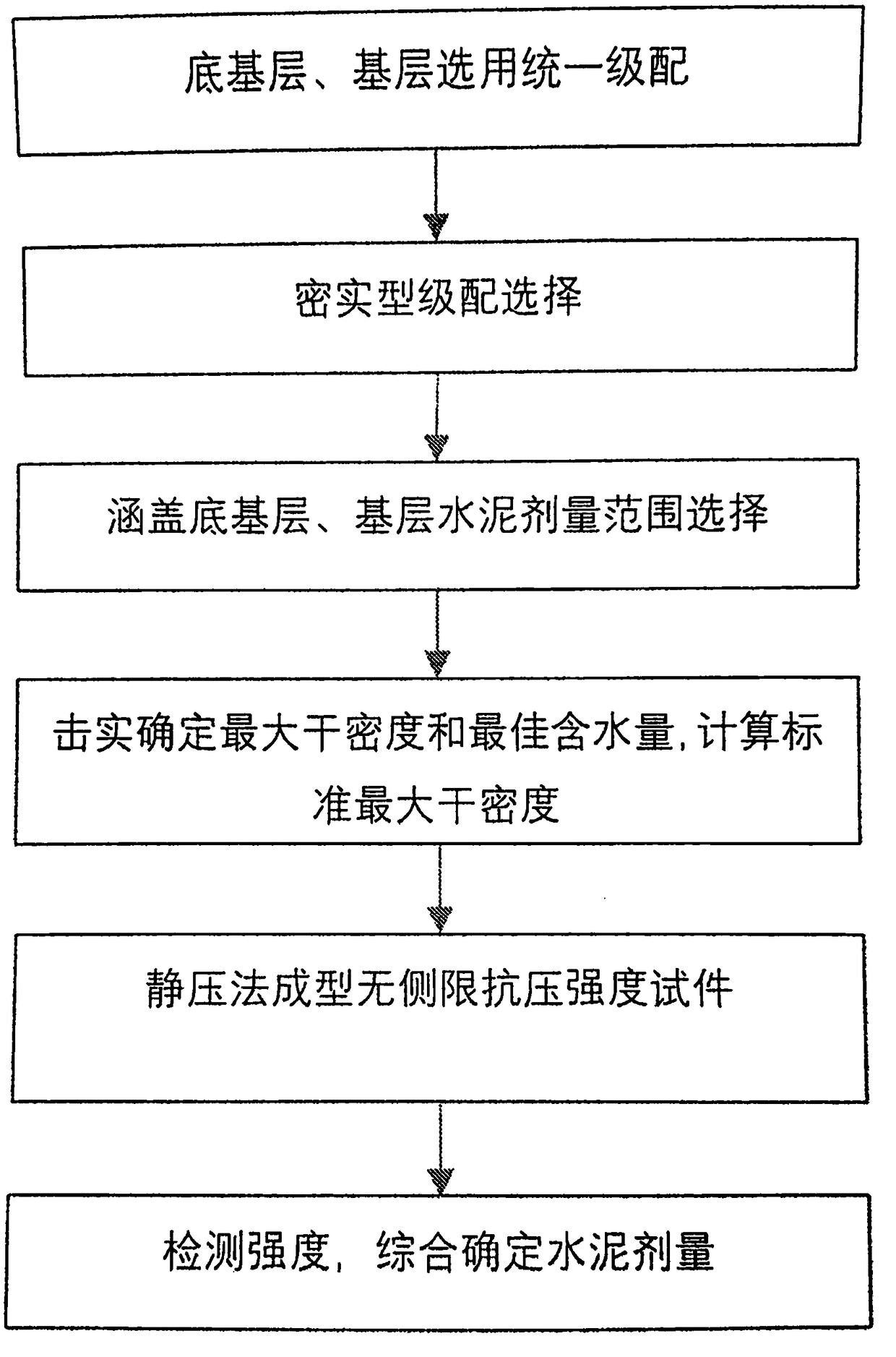

[0025] A method for one-time design of dense water-stabilized gravel subbase and base mix ratio, the specific steps are as follows.

[0026] Step 1, select the unified gradation type for sub-base and base.

[0027] A certain national highway in Inner Mongolia is dedicated to coal transportation, and there are many overweight vehicles, and the local area is arid and the extreme low temperature can reach -28°C.

[0028] In terms of structural load-bearing and crack resistance, both the subbase and base course adopt a dense skeleton structure, and the gradation is close to C-B-3. The recommended gradation is shown in Table 1, and the finer C-B-1 (as the subbase) and C-B-2 (as the The base layer) has more advantages than the latter, which has finer gradation, low load-bearing capacity, easy to crack, and requires multiple designs and a lot of experimental work.

[0029] Step 2, select dense gradation.

[0030] Design 3 mineral material gradations;

[0031] Table 1 gradation of ...

Embodiment 2

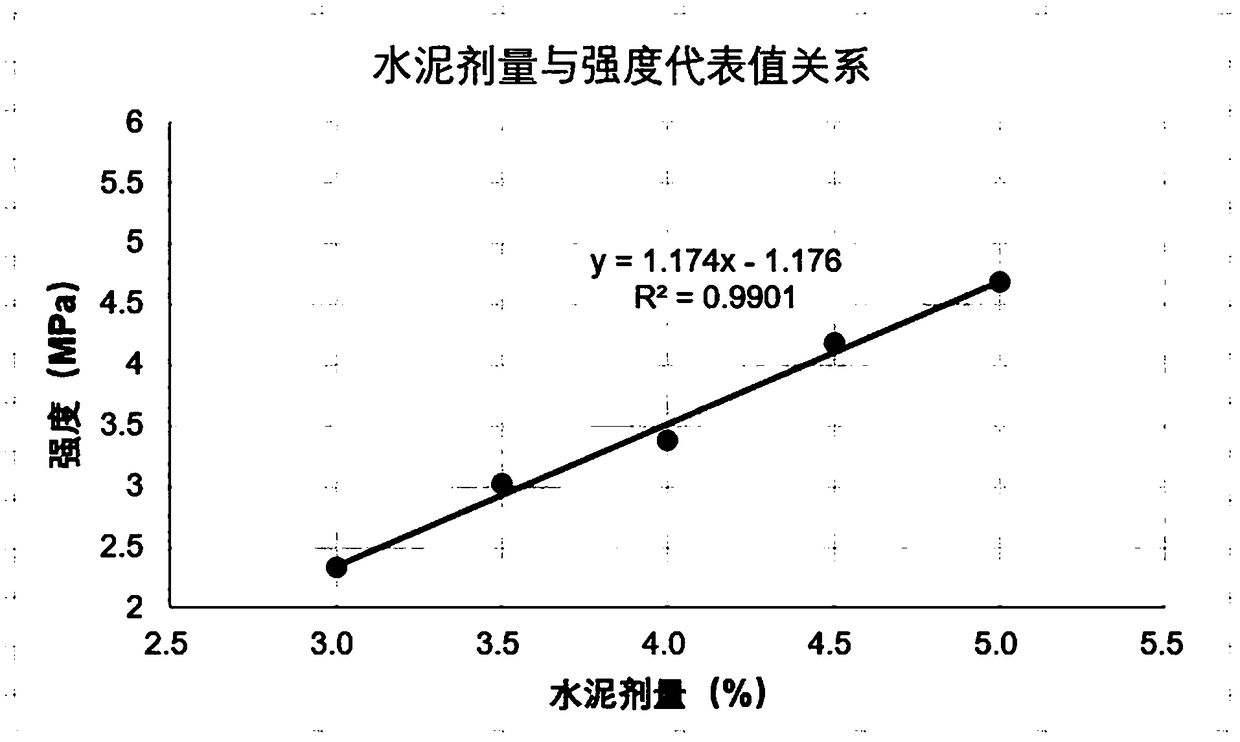

[0047] A method for one-time design of dense water-stabilized gravel subbase and base mix ratio, the specific steps are as follows.

[0048] Step 1, select the unified gradation type for sub-base and base.

[0049] There are many vehicles on a certain expressway in Chongqing, and it has the characteristics of high temperature and rain in summer and warm winter.

[0050] In terms of structural load-bearing and crack resistance, both the subbase and base course adopt a dense skeleton structure, and the gradation is close to C-B-3. The recommended gradation is shown in Table 1, and the finer C-B-1 (as the subbase) and C-B-2 (as the Compared with the base layer), it has more advantages, and can realize the problem of large load-bearing weight and high temperature during construction, which is easy to cause cracks. The integrated design saves the workload of the test in the design.

[0051] Step 2, select dense gradation.

[0052] Design 3 mineral material gradations, and the mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com