Method for non-blasting rock hole excavation construction of water grinding drill

A water-milling, non-blasting technology, applied in earth-moving drilling, mining equipment, tunnels, etc., can solve problems such as high cost and adaptability to polluted areas, and achieve no operation dust, low mechanical noise, and less interference with the surrounding environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

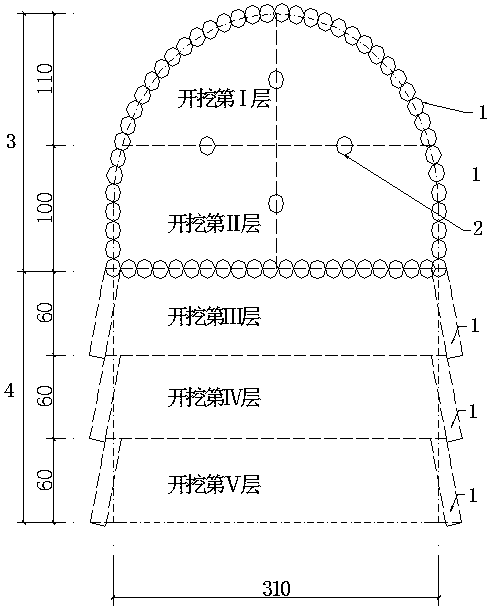

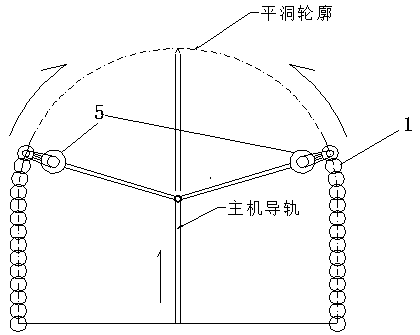

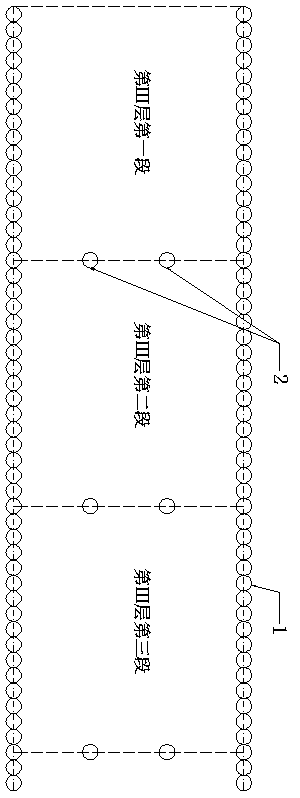

[0024] The technical solutions of the present invention will be further elaborated and described below with reference to the accompanying drawings and specific embodiments.

[0025] A method for digging and constructing non-blasting stone square holes with water mill drilling, the construction method is applied to the emergency rescue project of Wolonggou Reservoir in Jiangjin District, Chongqing City, and the specific project overview is as follows:

[0026] The grouting flat hole on the left bank of the emergency rescue project of Wolonggou Reservoir in Jiangjin District, Chongqing City has a total length of 50m, a section size of 3.1m×4.1m, a floor slope of 1%, and a floor elevation of 966.73m, which is 3.70m above the dam crest. The project is located in the national 5A-level scenic area and belongs to the third category of dangerous dams. In order to overcome the disturbance caused by drilling and blasting on the original buildings and the impact of local tourism, and ensu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com