Airflow guide reversing valve structure for circulating homogenizing device for foam materials and bottle flakes

A technology of a homogenizing device and a reversing valve, which is applied in the valve shell structure, valve device, valve operation/release device, etc., can solve problems such as affecting fiber quality, and achieve the effect of concise overall structure, convenient assembly and convenient production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

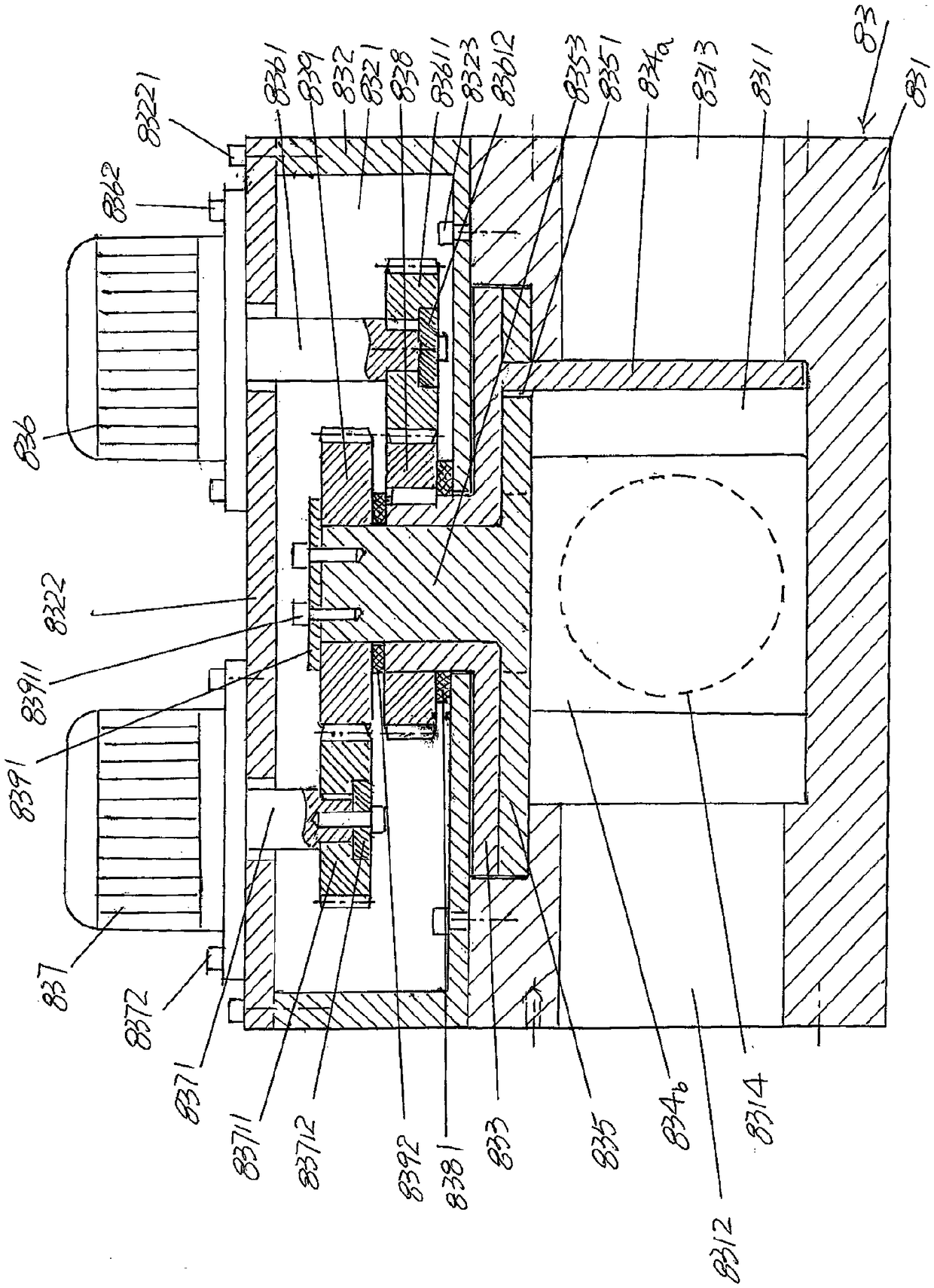

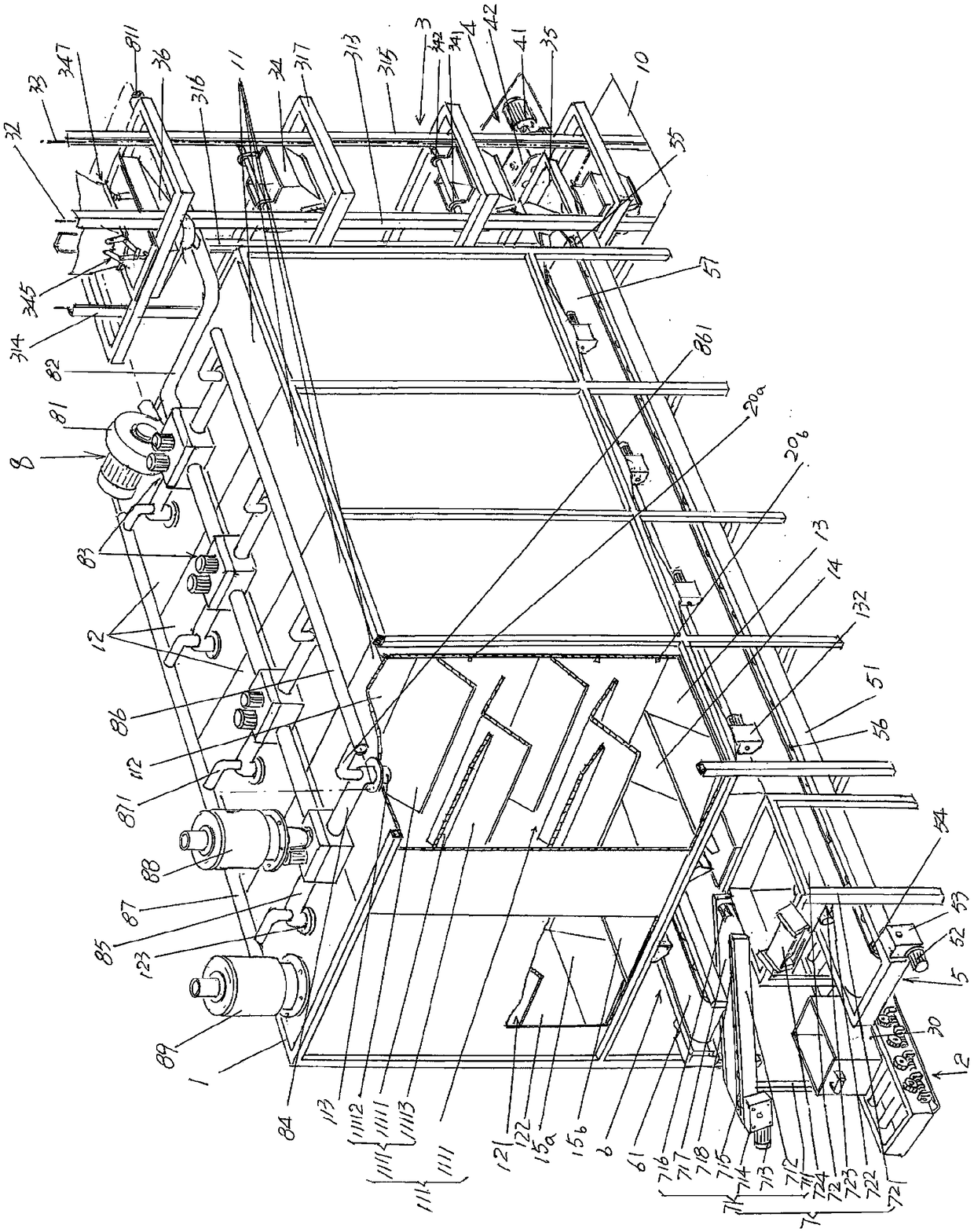

[0025] In the following descriptions, all concepts related to directionality or orientation of up, down, left, right, front and back are based on image 3 The shown position status is a reference, so it cannot be understood as a special limitation on the technical solution provided by the present invention. For example Figure 9 and Figure 10 The left, right, front and back of the position shown are exactly the same as image 3 In contrast to the position status, the applicant is in the Figure 9 and Figure 10 When explaining, still use image 3 The current position status is the reference.

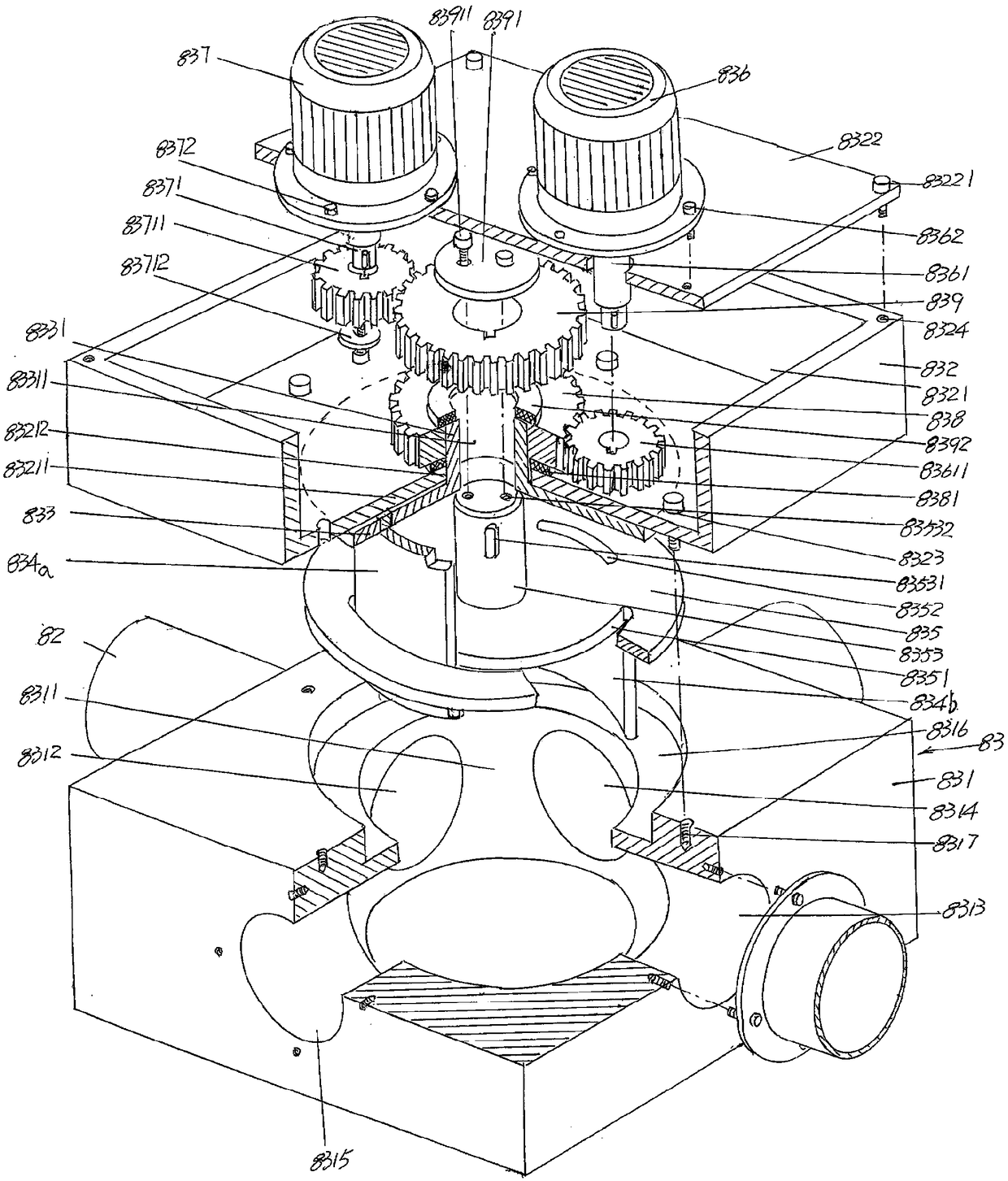

[0026] See figure 1 and figure 2, shows the air flow guide material reversing valve assembly 83, the air flow guide material reversing valve assembly 83 includes a valve seat 831, a gear box 832, an upper valve disc 833, an arc-shaped upper valve 834a, a lower valve disc 835, an arc-shaped lower valve disc The valve 834b, the upper valve disc drive motor 836, the lower valve di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com