Boiler waste heat collector

A boiler waste heat and heat collector technology, applied in fluid heaters, lighting and heating equipment, reducing greenhouse gases, etc., can solve the problems of boiler recovery, waste, and reduced equipment practicability, so as to save energy costs and ensure sealing High efficiency, good effect of waste heat recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

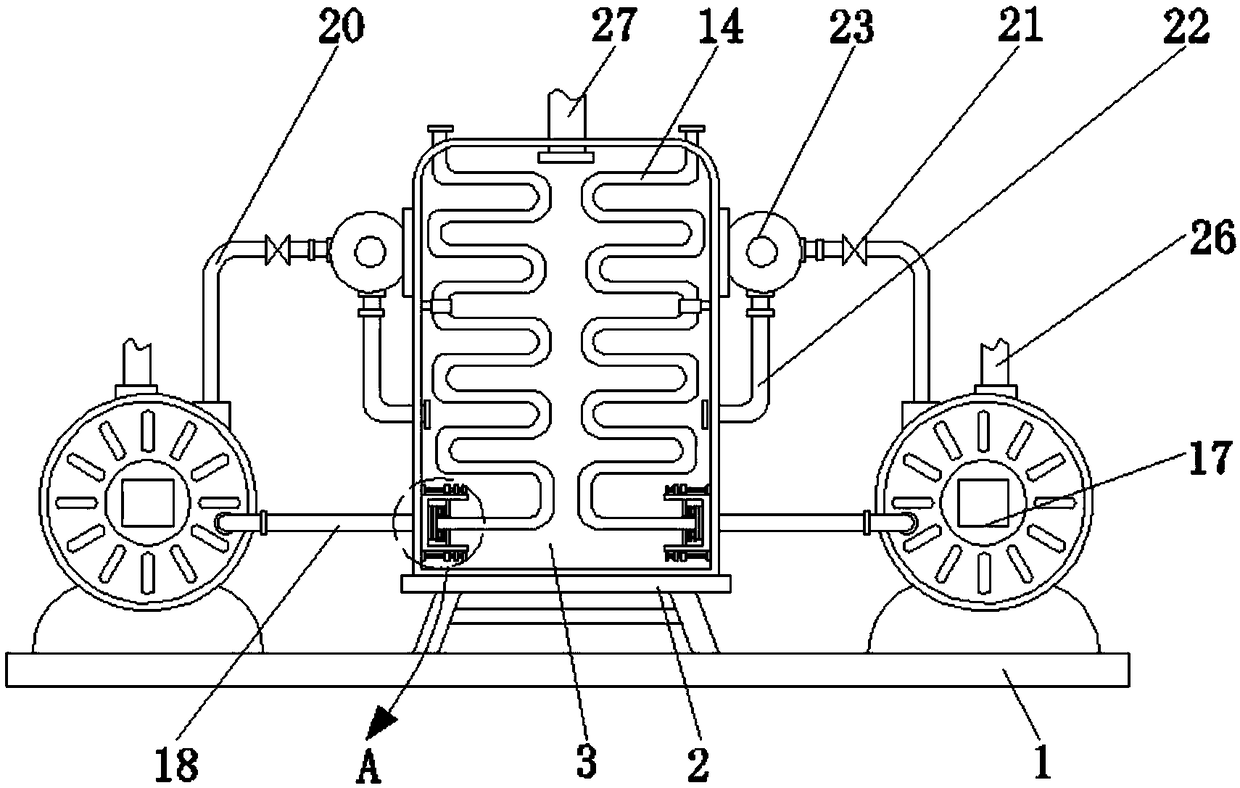

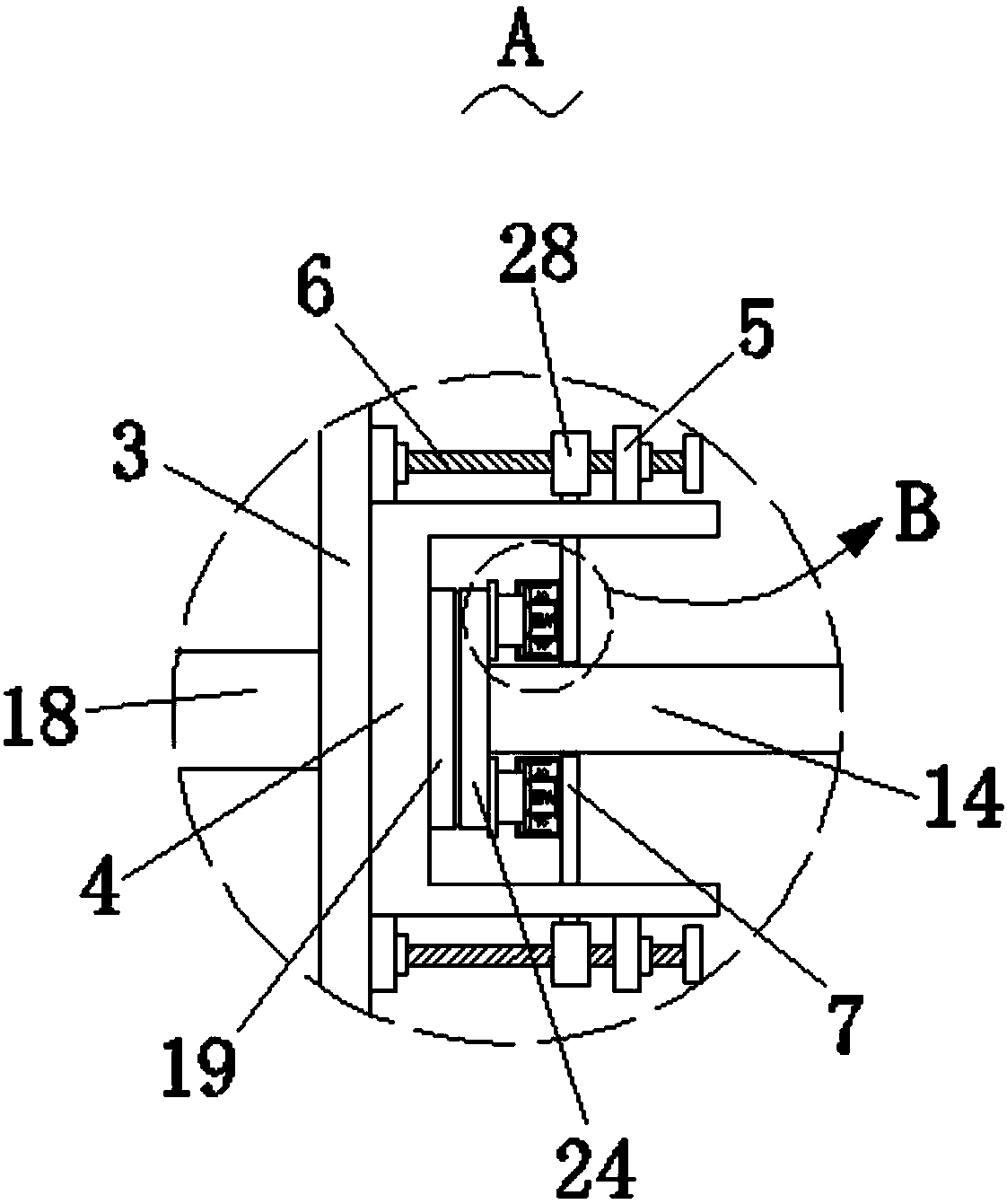

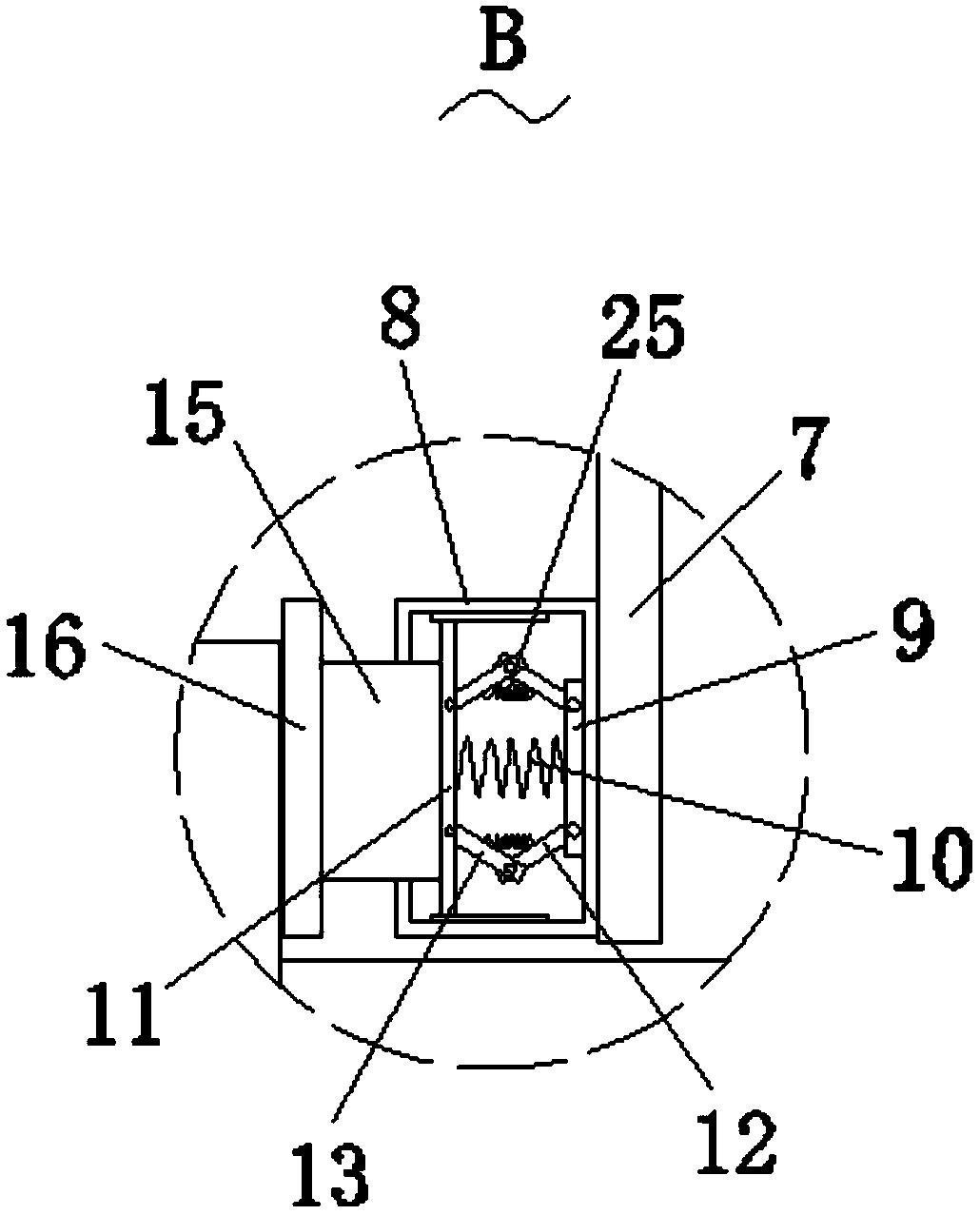

[0027] Please refer to figure 1 , figure 2 and image 3 ,in, figure 1 A schematic structural diagram of a preferred embodiment of the boiler waste heat collector provided by the present invention; figure 2 for figure 1 The enlarged schematic diagram of part A shown; image 3 for figure 2 The enlarged schematic diagram of part B is shown. The boiler waste heat collector includes: a bottom plate 1; a support frame 2, the support frame 2 is fixed on the top of the bottom plate 1; a preheating chamber 3, the bottom of the preheating chamber 3 is fixed on the top of the support frame 2 Two U-shaped blocks 4, two U-shaped blocks 4 are respectively fixed on both sides of the inner wall of the preheating chamber 3, and both sides of the top and bottom of the U-shaped block 4 are fixedly connected with a fixed plate 5 A threaded rod 6 is rotatably con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com