Sensitized optical fiber acoustic sensor probe and its sensitized structure

A sensor probe and sensitization structure technology, applied in the field of optical fiber sensing technology and acoustic wave detection, can solve problems such as unsatisfactory, and achieve the effects of low detection limit, few parts and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

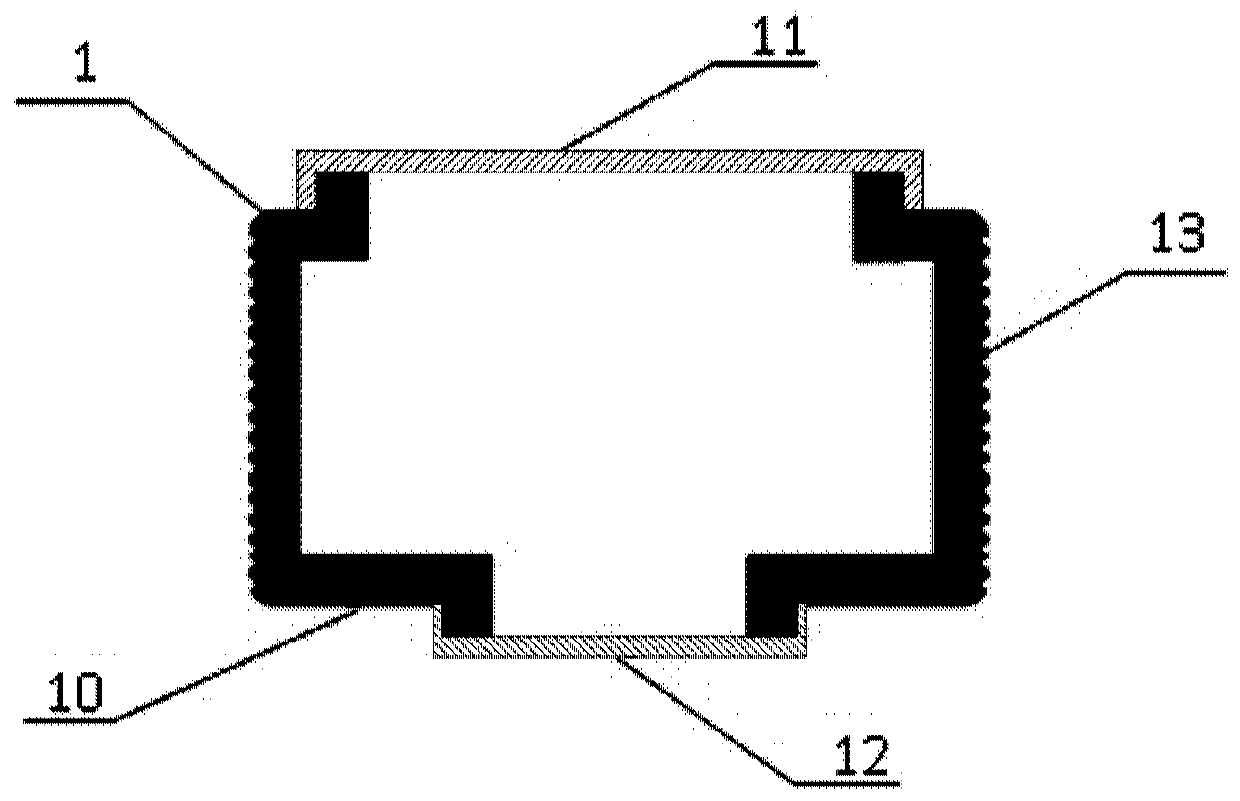

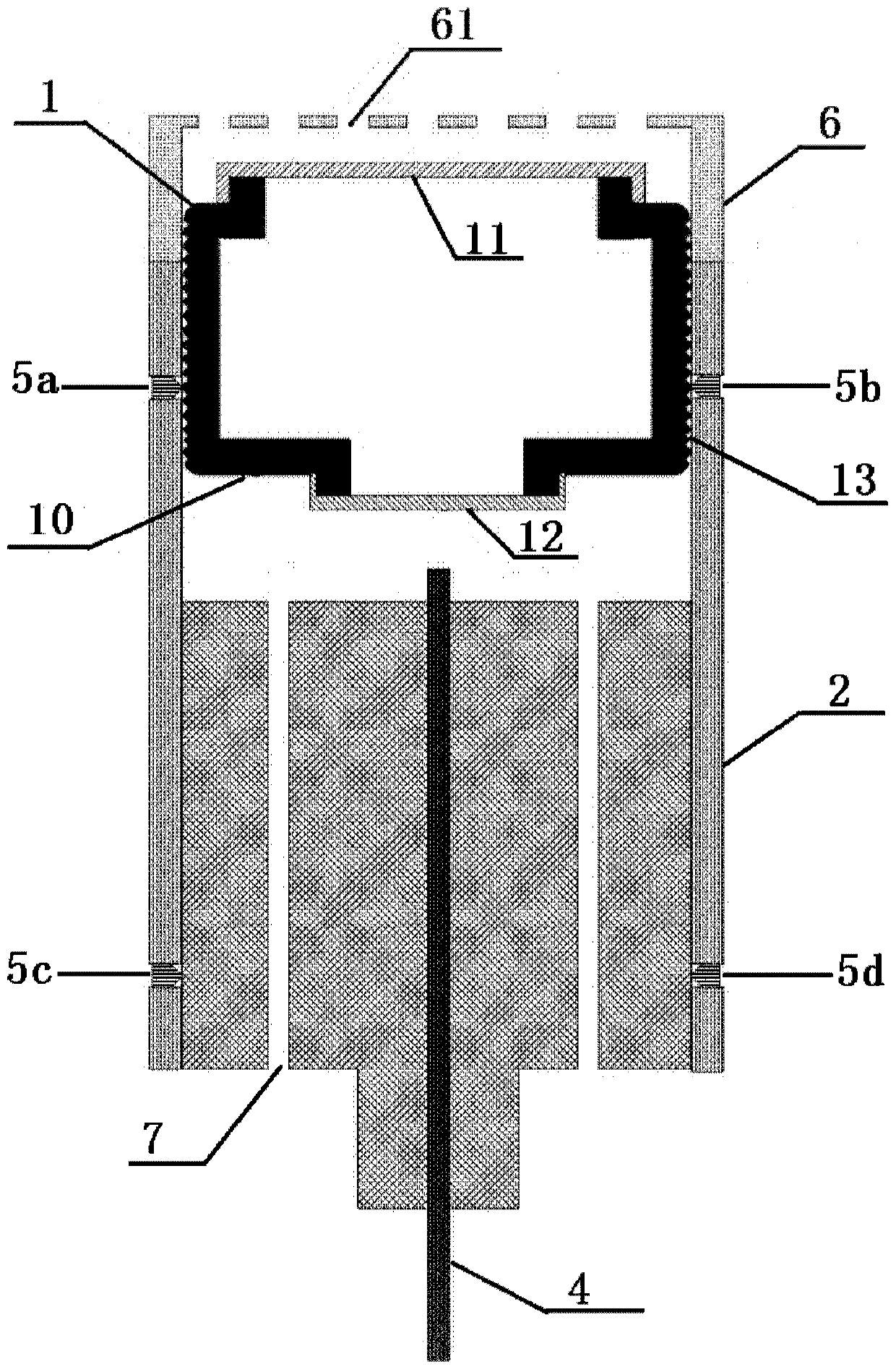

[0057] In the first exemplary embodiment of the present invention, a sensitization-type fiber optic acoustic sensor probe and a sensitization structure thereof are provided. figure 1 It is a sectional view of the sensitization structure of the sensitization optical fiber acoustic sensor probe of the first embodiment of the present invention; figure 2 It is a sectional view of the probe of the intensified optical fiber acoustic sensor according to the first embodiment of the present invention.

[0058] like figure 1 As shown, the sensitization structure 1 of the sensitization optical fiber acoustic sensor probe of this embodiment includes a first casing 10, a first diaphragm 11 and a second diaphragm 12, wherein the first casing 10 has a first port and a second Two ports, and the size of the first port is larger than the second port, the first diaphragm 11 is tightly covered on the first port, the second diaphragm 12 is tightly covered on the second port, and the second diaph...

no. 2 example

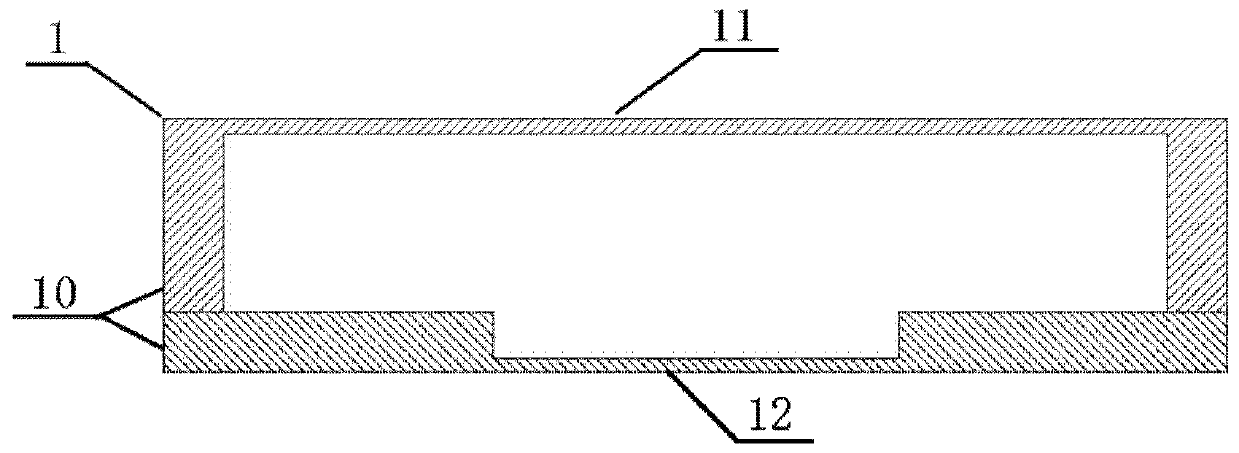

[0080] In the second exemplary embodiment of the present invention, a sensitization-type fiber optic acoustic sensor probe and a sensitization structure thereof are provided. image 3 It is a sectional view of the sensitization structure of the sensitization optical fiber acoustic sensor probe of the second embodiment of the present invention; Figure 4 It is a cross-sectional view of the probe of the intensified optical fiber acoustic sensor according to the second embodiment of the present invention.

[0081] like image 3 As shown, the sensitization structure 1 of the sensitization optical fiber acoustic sensor probe of this embodiment is similar to that of the first embodiment, the difference is that:

[0082] In this embodiment, the sensitization structure 1 is a silicon-based or glass-based MEMS structural element, and the first housing 10 is formed by aligning and bonding a two-layer supporting structure provided with a first membrane 11 and a second membrane 12 respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com