Fabrication method of micro-nano structure and system used in the fabrication method

A production method and technology of micro-nano structure, applied in the direction of photo-plate-making process of pattern surface, micro-lithography exposure equipment, photo-plate-making process exposure device, etc., can solve the problems of lower resolution of nano-processing and lower precision of micro-nano structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

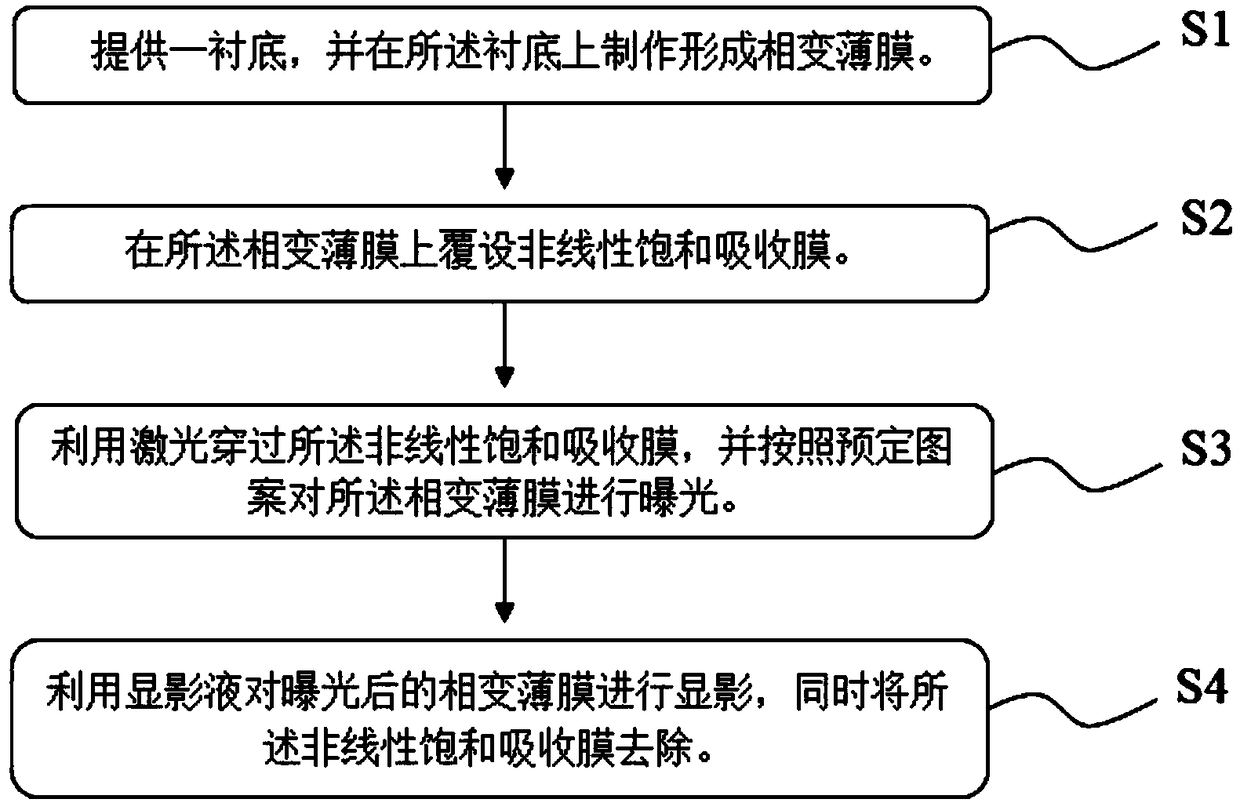

[0029] refer to figure 1 , the present embodiment provides a method for fabricating a micro-nano structure, comprising the steps of:

[0030] S1. Provide a substrate, and fabricate and form a phase change film on the substrate;

[0031] S2. Covering the phase change film with a nonlinear saturable absorption film;

[0032] S3, using a laser to pass through the nonlinear saturable absorption film, and exposing the phase change film according to a predetermined pattern;

[0033] S4. Using a developing solution to develop the exposed phase change film, and remove the nonlinear saturable absorption film at the same time.

[0034] The fabrication method of the micro-nano structure provided by the present invention exposes the phase-change thin film by passing the laser through the nonlinear saturable absorption film, and utilizes the nonlinear saturable absorption characteristics of the nonlinear saturable absorption film, and the nonlinear saturable absorption The absorption of...

Embodiment 2

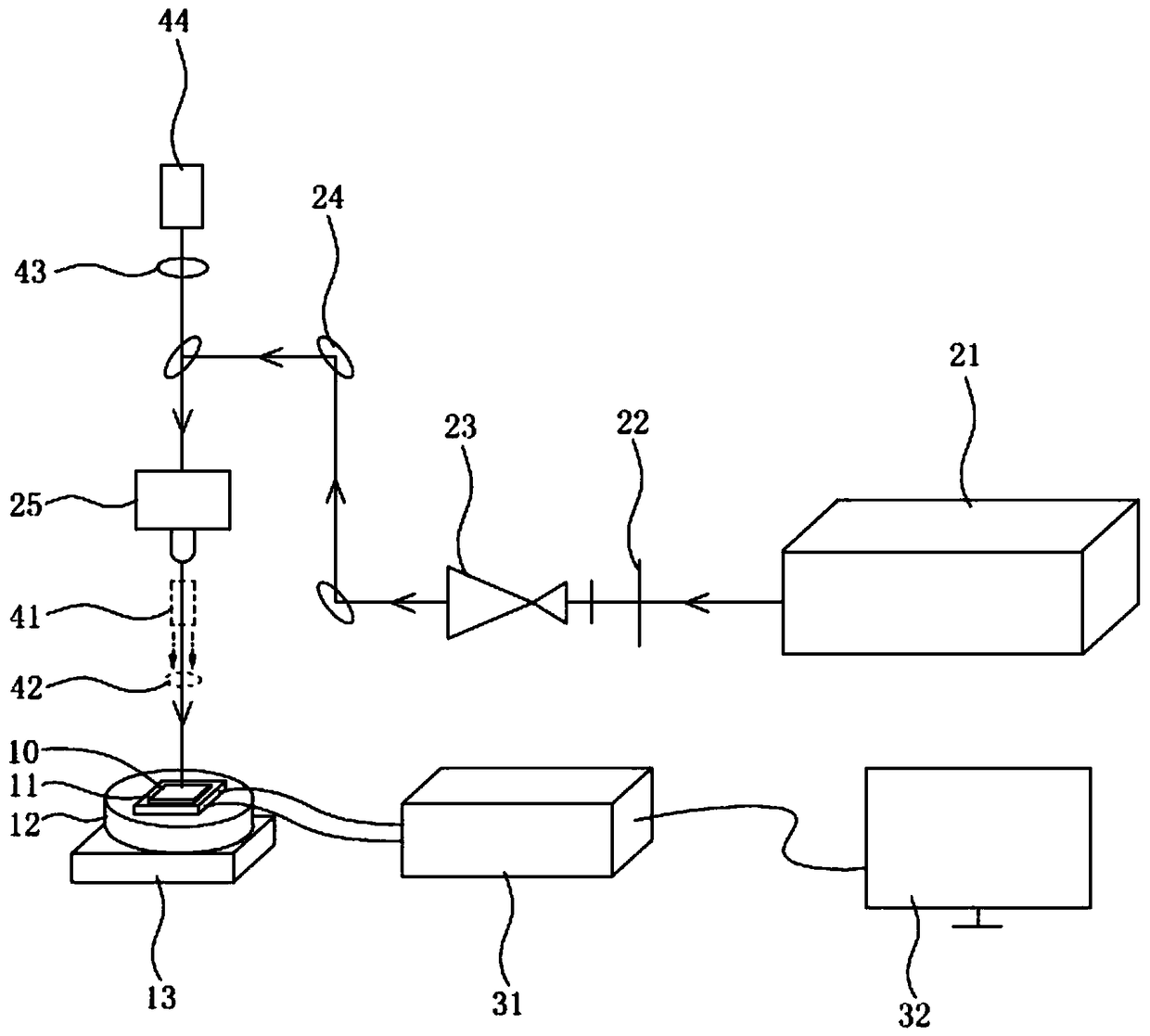

[0045] Such as figure 2 As shown, this embodiment also provides a system used in the above-mentioned method for fabricating the micro-nano structure, which is mainly applied in the above-mentioned step S3. The system includes a piezoelectric stage, a laser component, a control component and an imaging component. Wherein, the piezoelectric stage is used to carry an object, and the signal generated by pressing the object on the piezoelectric stage is transmitted to the control component; the laser component is used to emit laser light to irradiate the object; The control component is used to determine the position of the object on the piezoelectric stage according to the signal, and is used to move the object according to a predetermined pattern; the imaging component is used to image the object to Monitor the object.

[0046] Specifically, the piezoelectric stage includes a manual lifting platform 13, a manual translation platform 12, and a piezoelectric seat 11 stacked in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com