A method for analyzing fatigue crack propagation of particle composite material

A crack fatigue propagation, composite material technology, applied in the field of particle reinforced metal matrix composite materials, can solve problems such as inability to simplify two-dimensional problems into one-dimensional problems, difficulty in finite element modeling, increase computational workload, etc., and achieve fast calculation speed. , the effect of reducing the amount of calculation and improving the calculation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

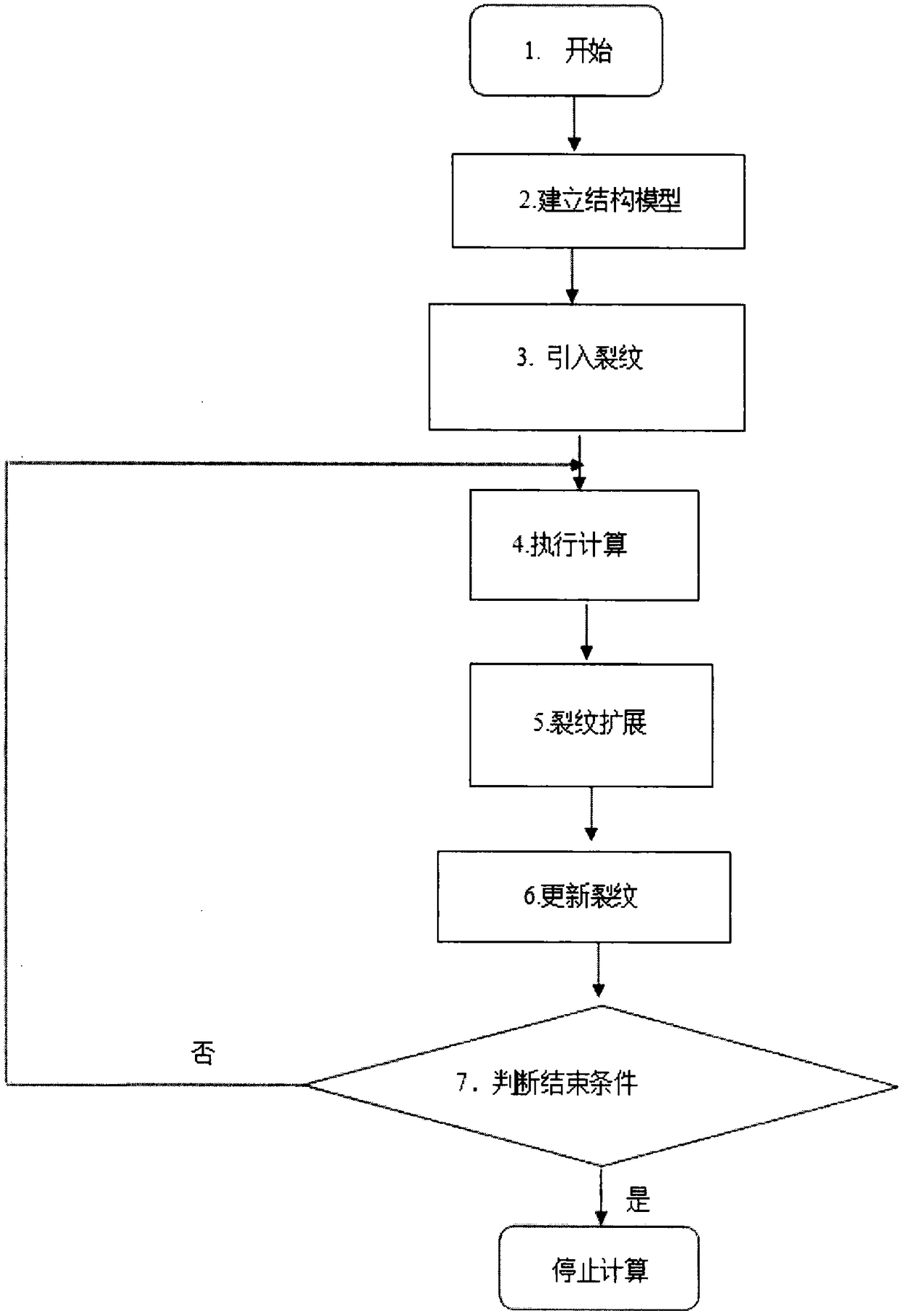

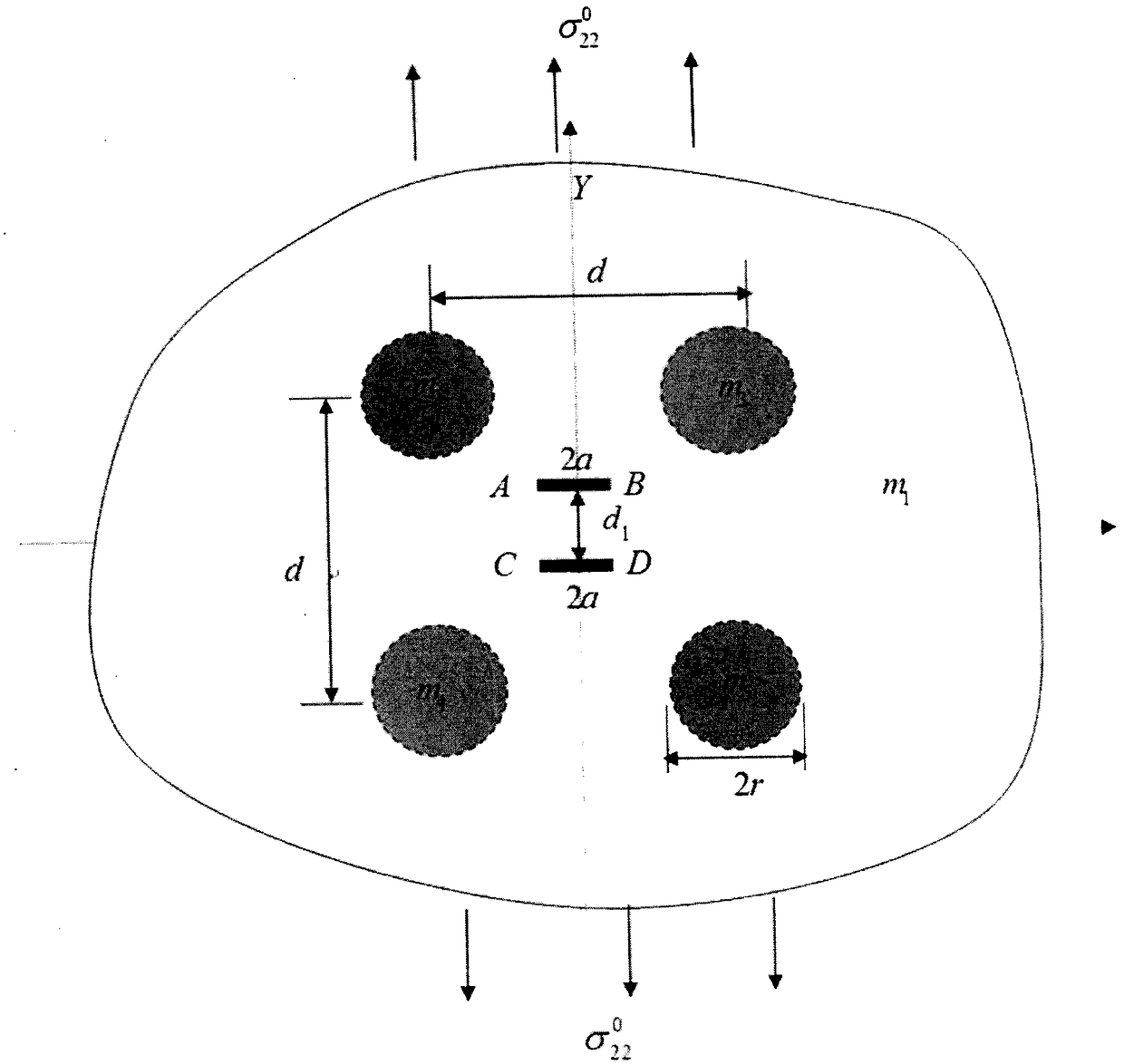

[0034] Such as figure 2 As shown, this system is used to analyze the fatigue crack growth of the following example granular composite materials.

[0035] 1. Enter the geometric model information:

[0036] 2. Input load information;

[0037] 3. Input fatigue crack growth information;

[0038] 4. After clicking Calculate, you can get the running result;

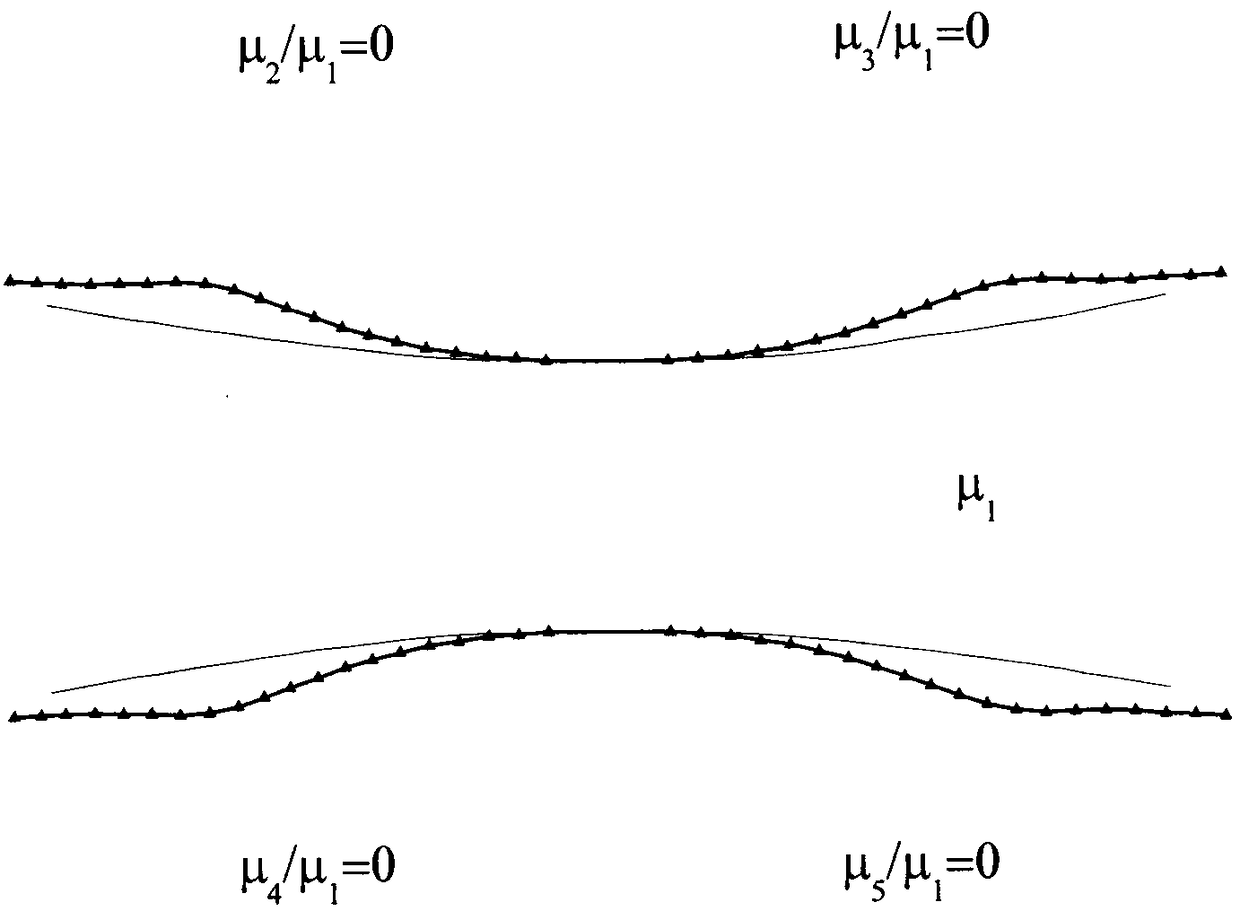

[0039] 5. After post-processing, the crack propagation path can be obtained, such as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com