A multi-person collaborative maintenance system and method for a thermal power plant based on AR glasses, and an AR glasses

A technology of AR glasses and thermal power plants, applied in the maintenance of power plants, multi-person collaborative maintenance based on AR glasses, can solve the problems of insufficient equipment status data mining, further support, and insufficient management methods, etc., to achieve effective It is beneficial to standardize operation, improve equipment reliability and ensure efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

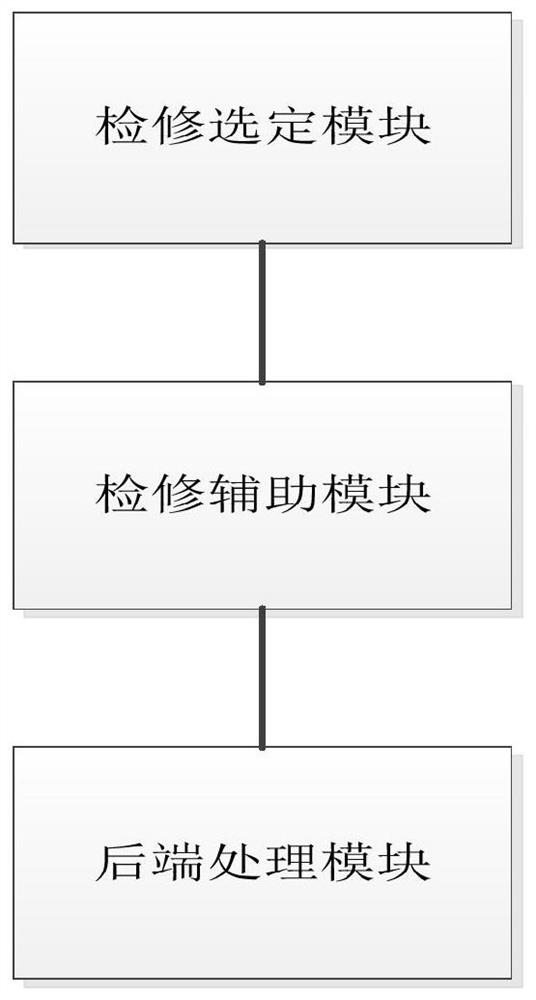

[0048] Such as figure 1 As shown, a multi-person collaborative maintenance system for thermal power plants based on AR glasses includes: a maintenance selection module and a maintenance auxiliary module stored and operated in the AR glasses, wherein:

[0049] Overhaul selection module, which has several overhaul operation items that can be selected;

[0050] The maintenance auxiliary module includes a current operation tab corresponding to the selected maintenance operation item, and the current operation tab includes: a work instruction unit capable of displaying prompt information through AR glasses and a user operation for changing the state of the selected maintenance operation item The unit, that is, the operation instruction unit, prompts the prompt information of the selected maintenance operation item by means of text description, which plays the role of auxiliary maintenance. At the same time, the user can also perform operations such as confirmation and sharing of th...

Embodiment 2

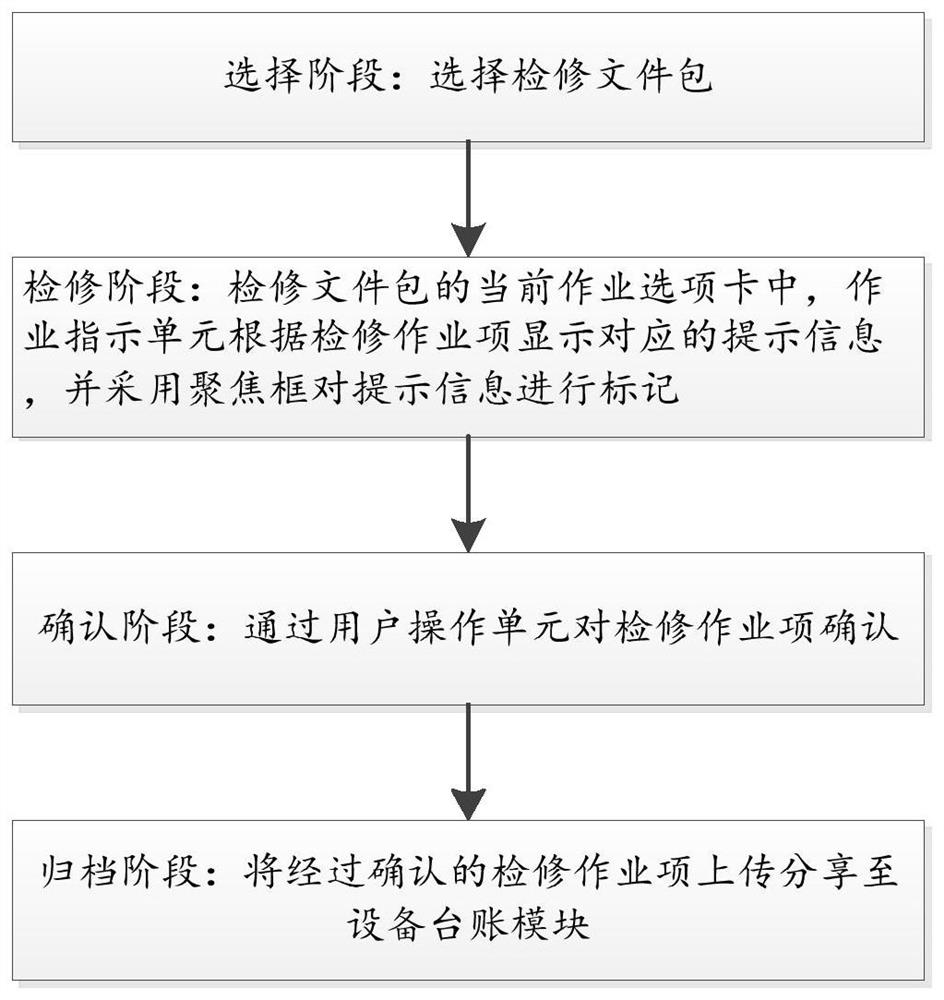

[0073] This embodiment discloses its maintenance method based on the system of Embodiment 1, specifically as follows:

[0074] Such as figure 2 As shown, the present invention also discloses a multi-person collaborative maintenance method in a thermal power plant based on AR glasses. The specific method is as follows:

[0075] Selection stage: select the maintenance file package;

[0076] Maintenance phase: In the current operation tab of the maintenance file package, the work instruction unit displays the corresponding prompt information according to the maintenance work item, and uses the focus box to mark the prompt information;

[0077] Confirmation stage: confirm the maintenance work items through the user operation unit;

[0078] Archiving stage: Upload and share the confirmed maintenance work items to the back-end processing module.

[0079] In this embodiment, the maintenance phase also includes: displaying image information for action guidance according to the mai...

Embodiment 3

[0094] The present invention also discloses AR glasses, which can store and run the maintenance system disclosed in Embodiment 1. The structure of existing AR glasses is consistent with the AR glasses disclosed in this embodiment, and the specific models are VuzixBlade 3000, ODG R7 / R8 / R9, Vuzix M300, etc., and the detailed structure will not be described redundantly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com