Method, system and storage device for predicting cleaning cycle of photovoltaic module

A technology for photovoltaic modules and cleaning cycles, applied in forecasting, system integration technology, information technology support systems, etc., can solve problems such as high cleaning costs, reduced power generation efficiency of photovoltaic modules, and failure to maximize power station benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

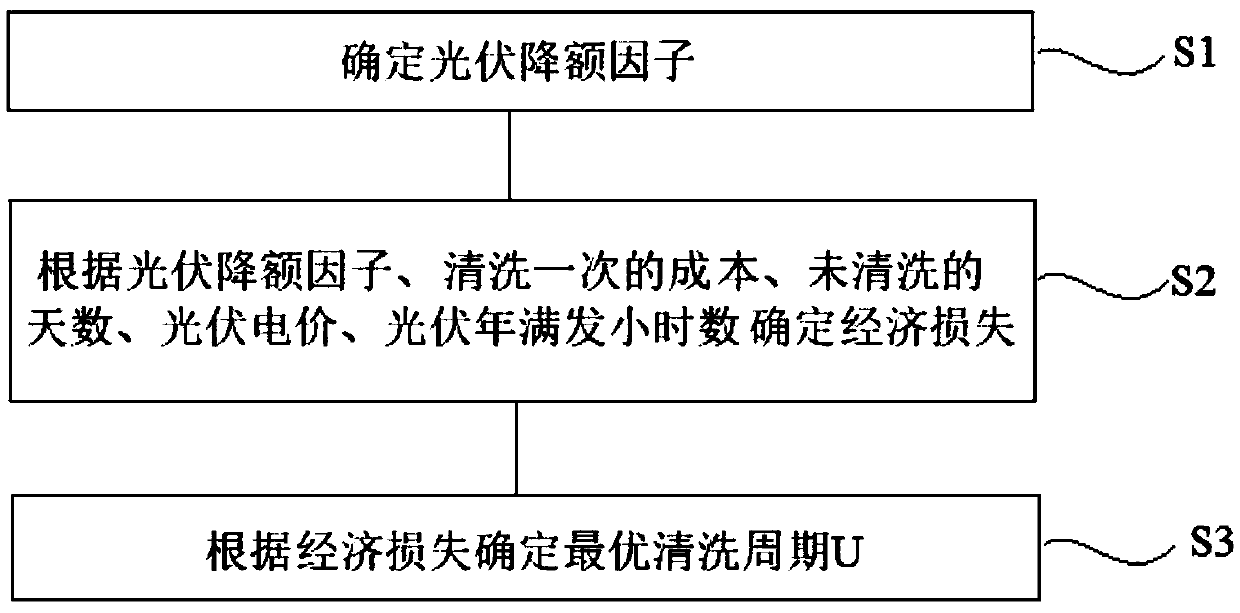

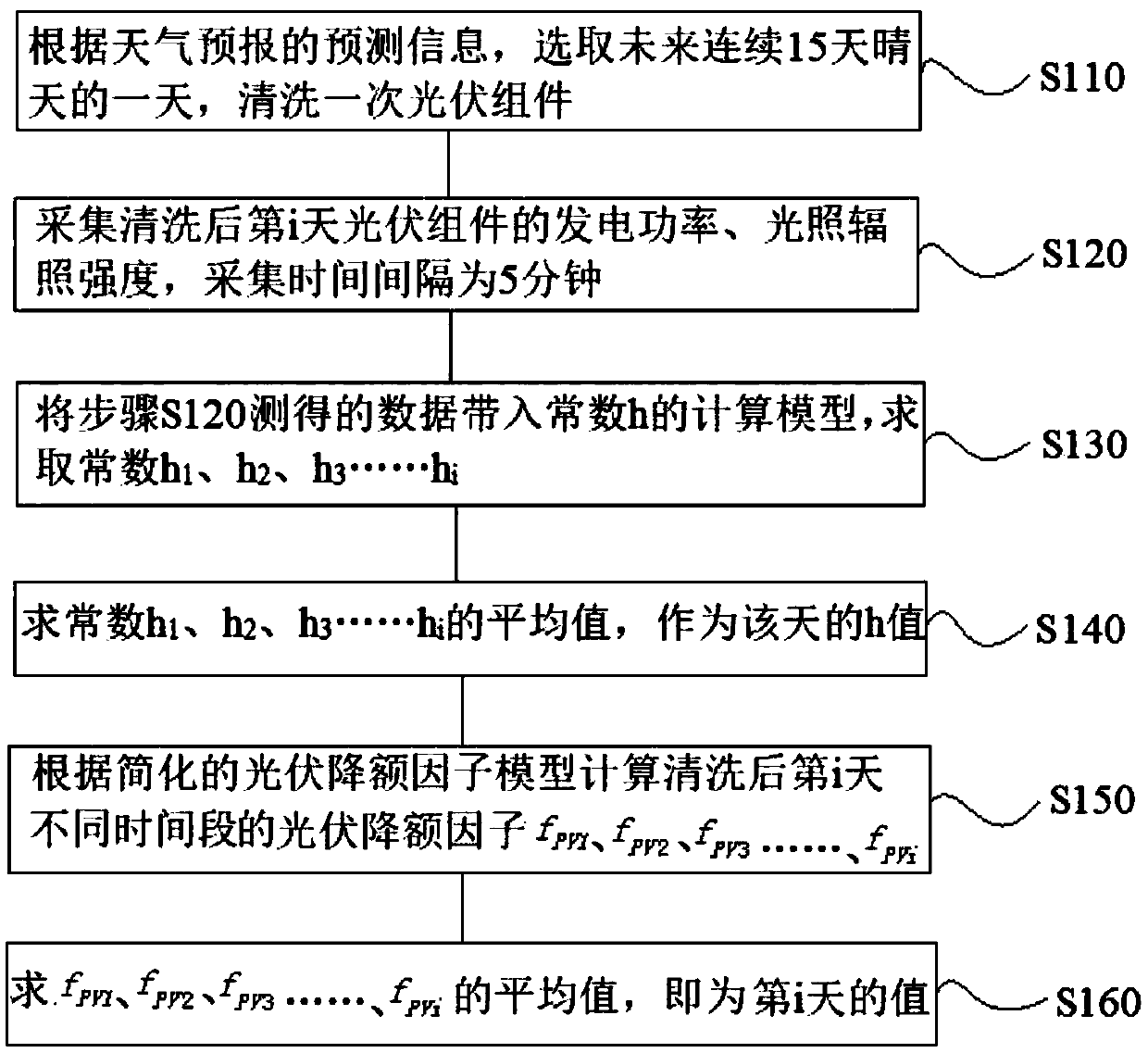

[0059] like figure 1 As shown, the method for predicting the cleaning cycle of the photovoltaic module according to the embodiment of the present invention mainly includes the following steps:

[0060] S1: Determine the photovoltaic derating factor;

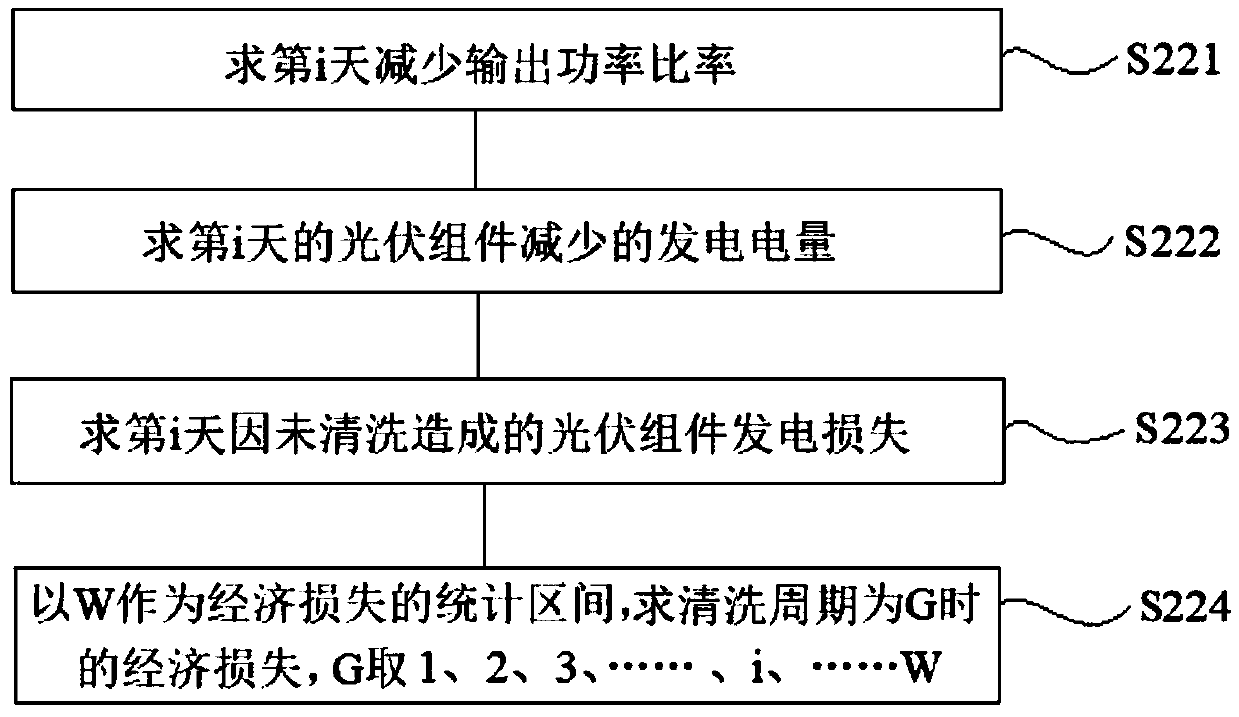

[0061] S2: Determine the economic loss based on the photovoltaic derating factor, the cost of cleaning once, the number of days without cleaning, the price of photovoltaic electricity, and the number of hours of full photovoltaic power generation in a year;

[0062] S3: Determine the optimal cleaning period U according to the economic loss.

[0063] The following is a detailed description of the prediction method of the cleaning cycle of photovoltaic modules as follows:

[0064] It is known that before the photovoltaic modules of the photovoltaic power station or micro-grid adopt this cleaning strategy, the fixed cleaning period used is W days, and the cost of cleaning the photovoltaic modules once is R yuan. The optimal cleani...

Embodiment 2

[0095] Compared with Embodiment 2, this embodiment differs in that the influence of the surface temperature of the photovoltaic module is considered. like Figure 5 As shown, in this embodiment, taking the i-th day as an example, the photovoltaic derating factor f of the i-th day after cleaning is calculated PV-i , to illustrate the calculation method of photovoltaic derating factor:

[0096] S111: According to the prediction information of the weather forecast, select a sunny day for 15 consecutive days in the future, and clean the photovoltaic module once;

[0097] S121: Determine the rated capacity of the photovoltaic module according to the scale of the photovoltaic module;

[0098] S131: Record the power generation, light irradiation data, and surface temperature of the photovoltaic module on the i-th day after cleaning, and the collection time interval is 5 minutes;

[0099] S141: Calculate the photovoltaic derating factor f in different time periods on the i-th day a...

Embodiment 3

[0103] Taking the historical data of an 8000kW photovoltaic power station in Shanghai for 8 days (because it is rainy in Shanghai, 8 days are selected as the sample data, but not limited to 8 days, the sample data time can be appropriately extended according to the local climate conditions.) as the sample, the simulation verification of this cleaning Algorithm effectiveness.

[0104] (1) Read the power generation power and light irradiation intensity of the photovoltaic modules on the first day after cleaning, and the light irradiation intensity and photovoltaic power generation power curve on the first day after cleaning are as follows: Image 6 and Figure 7 shown;

[0105] (2) According to the intensity of light irradiation and the power of photovoltaic power generation, the average value of the first day constant h after cleaning is calculated to be 1.873;

[0106] (3) After recording and cleaning, the power generation and light irradiation data of photovoltaic modules f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com