A lean logistics leveling distribution management system

A management system and logistics technology, applied in the direction of logistics, data processing applications, instruments, etc., can solve the problem of high cost of improvement, achieve the effects of precise execution, reduction of warehouse material distribution personnel, and real-time feedback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

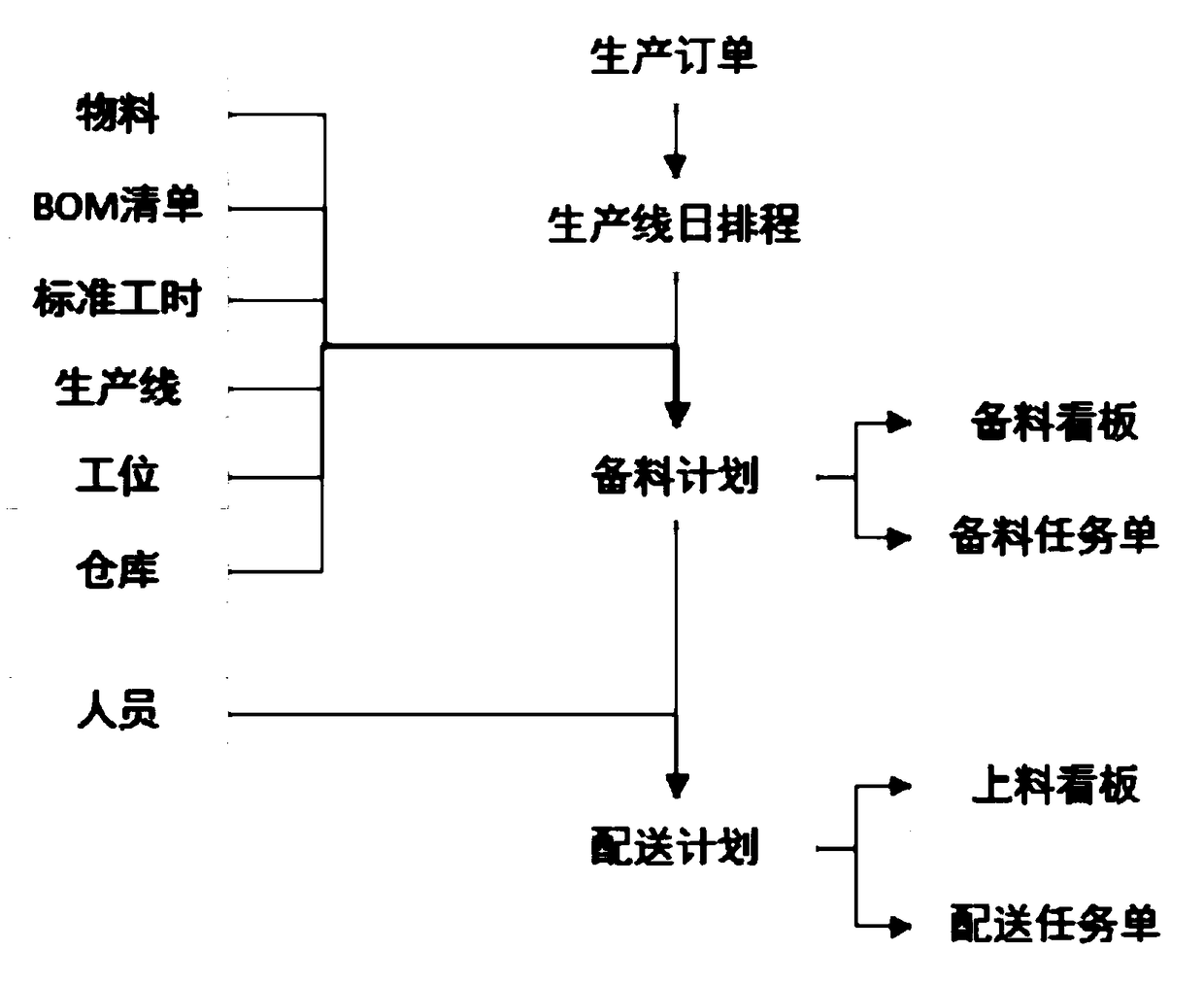

[0036] Such as figure 1 , A lean logistics leveling distribution management system of the present invention must first sort out materials, BOM lists, standard working hours, production lines, workstations, warehouse basic data, and then make a production line schedule table based on the production order, and then combine the basic data Make a material preparation plan, form a material preparation task list according to the material preparation plan, and the material preparation plan can be displayed on the material preparation kanban; then the material preparation plan combines the personnel information to make a distribution plan, and a distribution task list is formed according to the distribution plan, and the distribution plan can be displayed On the material board;

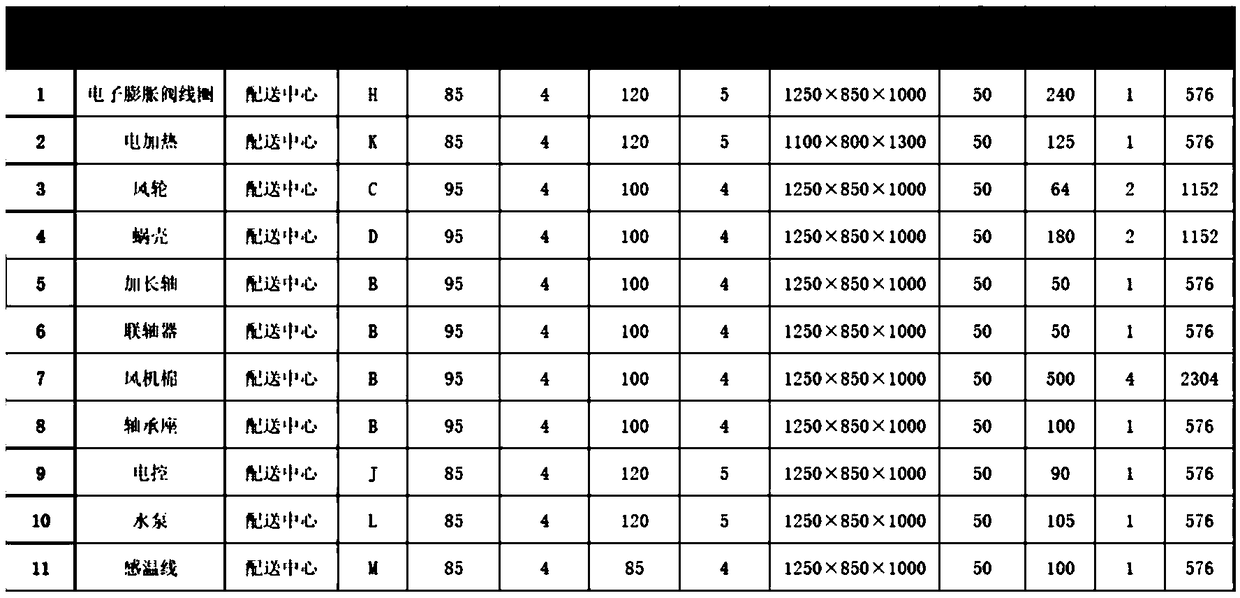

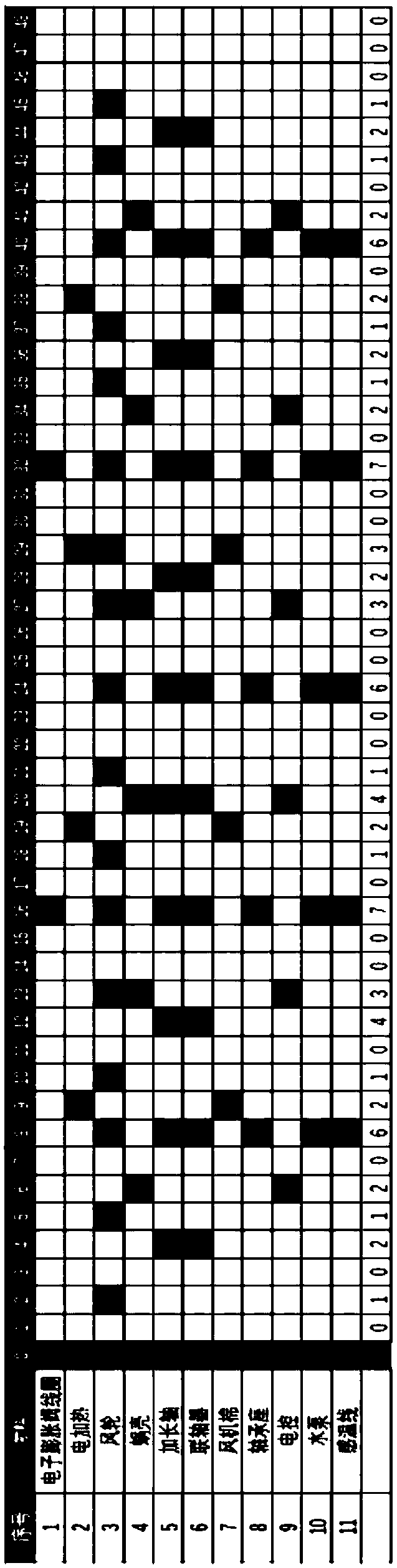

[0037] Such as figure 2 , The ingredients of a product in this embodiment include electronic expansion valve coils, electric heating, wind wheels, volutes, extension shafts, couplings, fan wool, bearing seats, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com