Preparation method of solid dispersant containing fucoidin and curcumin and application thereof

A technology of solid dispersion and fucoidan is applied in the directions of non-active ingredient medical preparations, medical preparations containing active ingredients, pharmaceutical formulas, etc. The preparation method is complex and other problems, so as to achieve the effect of preventing and treating gastric Helicobacter pylori infection, repairing ulcer tissue and reducing gastrointestinal inflammatory response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

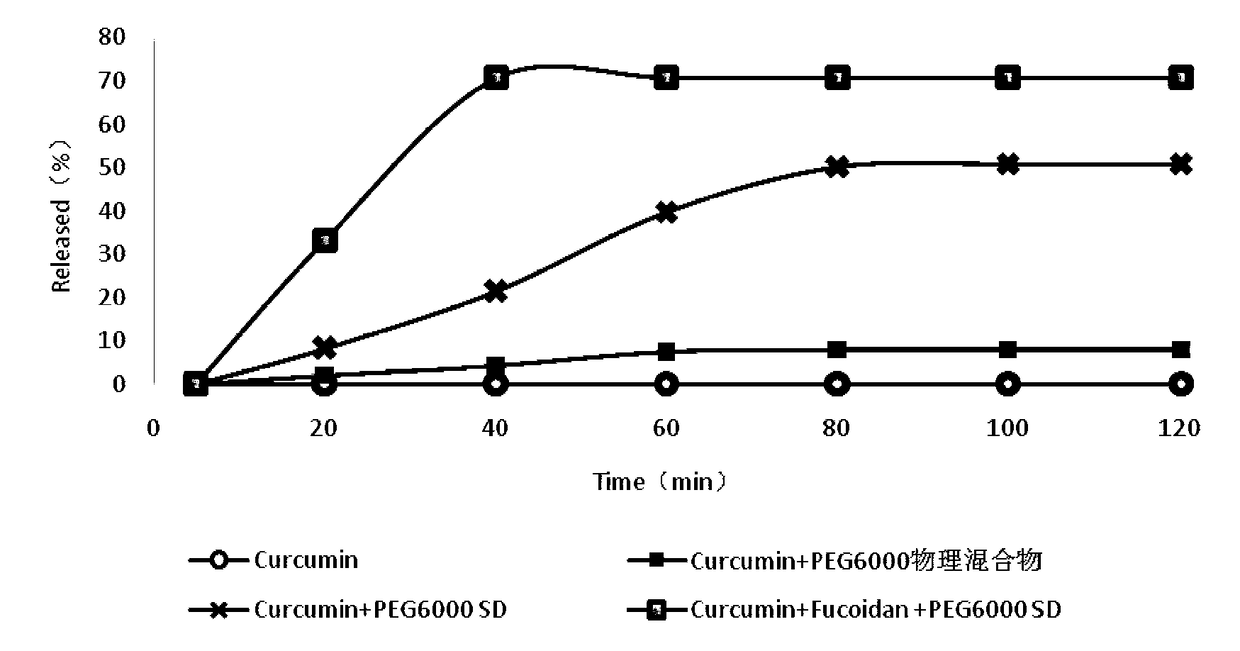

[0039] 1. Preparation of solid dispersion: weigh curcumin 0.4g and fucoidan 1.6g, PEG6000 2.0g (curcumin: fucoidan: PEG6000 is 1:4:5), mix well, put in a mortar and grind, The rotation speed is 500rpm, the grinding time is 90min, take it out, and pass through a 90-mesh sieve to obtain the product.

[0040] Comparative example experiment: accurately take by weighing about 0.04g of pure curcumin (according to the curcumin content in the solid dispersion is 10% calculation); The physical mixture (curcumin content 10%) of curcumin and PGE6000 is about 0.4g; Curcumin and PGE6000 Solid dispersion (curcumin content 10%) 0.4g, adopts above-mentioned same grinding method.

[0041] 2. Dissolution test evaluation.

[0042] ① Chromatographic conditions: Chromatographic column: DiamonsilC from Dikma Company (250mm×4.6mm); mobile phase: methanol: water: acetic acid (77:22:1); detection wavelength: 428nm; flow rate: 1.0mL / min; column temperature: 25°C .

[0043]②Standard curve: Accurately...

Embodiment 2

[0048] The difference from Example 1 is that 0.4g of curcumin, 2.0g of fucoidan, and 1.6g of PEG4000 are weighed, mixed evenly, and ground in a mortar with a rotation speed of 300rpm and a grinding time of 80min, taken out, and passed through an 80-mesh sieve to obtain Solid dispersion. The detection method is the same.

Embodiment 3

[0050] The difference from Example 1 is that 0.4g of curcumin, 2.0g of fucoidan, and 1.6g of PEG10000 are weighed, mixed evenly, and ground in a mortar with a rotation speed of 500rpm and a grinding time of 100min, taken out, and passed through a 90-mesh sieve to obtain . The detection method is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com