Rolling body full-surface defect detection method

A defect detection and rolling element technology, which is applied in sorting and other directions, can solve problems such as low detection efficiency, high cost, and impact on bearing quality and quality, and achieve the effect of simple device structure, low-cost detection, high-speed and reliable automatic detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Example when the rolling elements are rollers

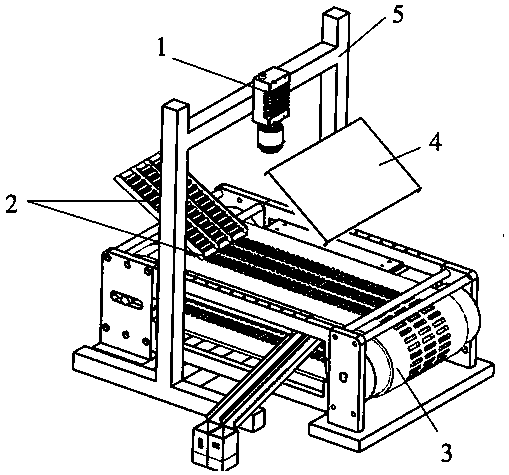

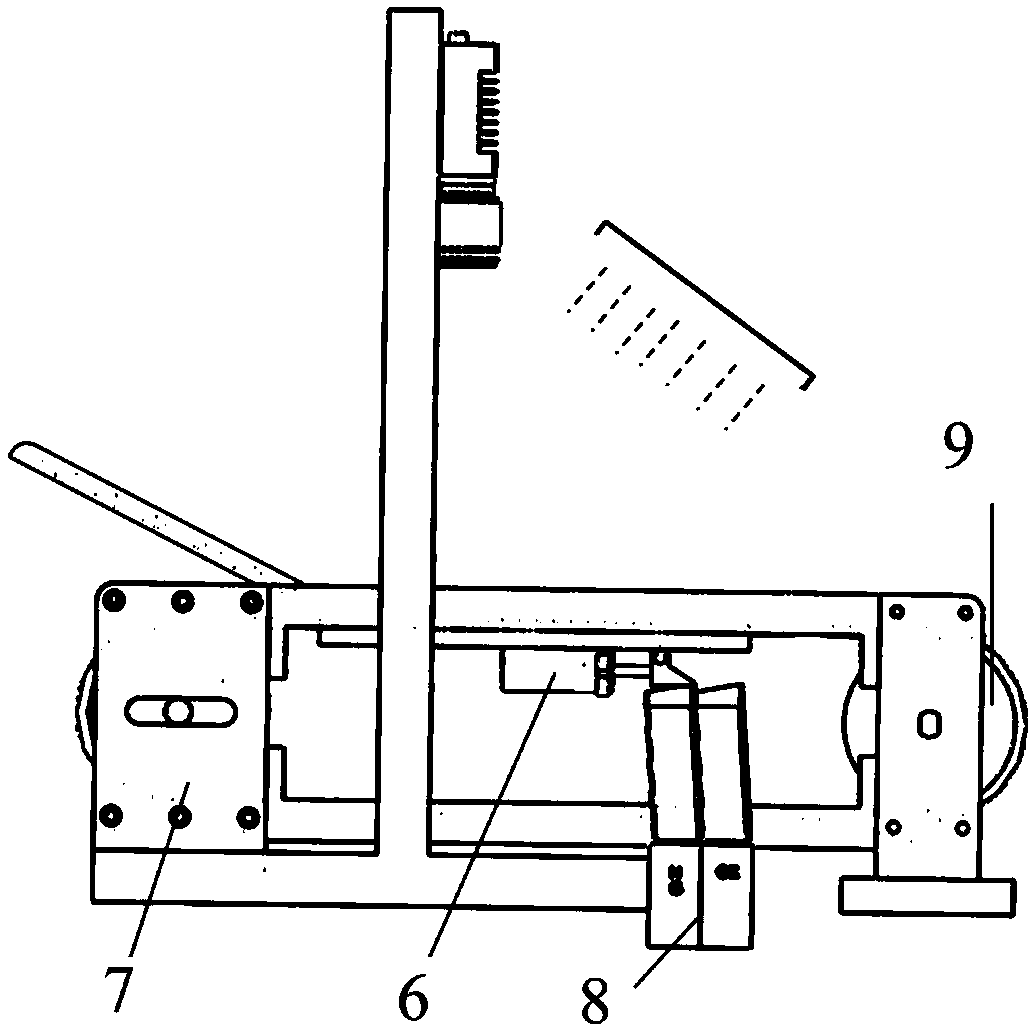

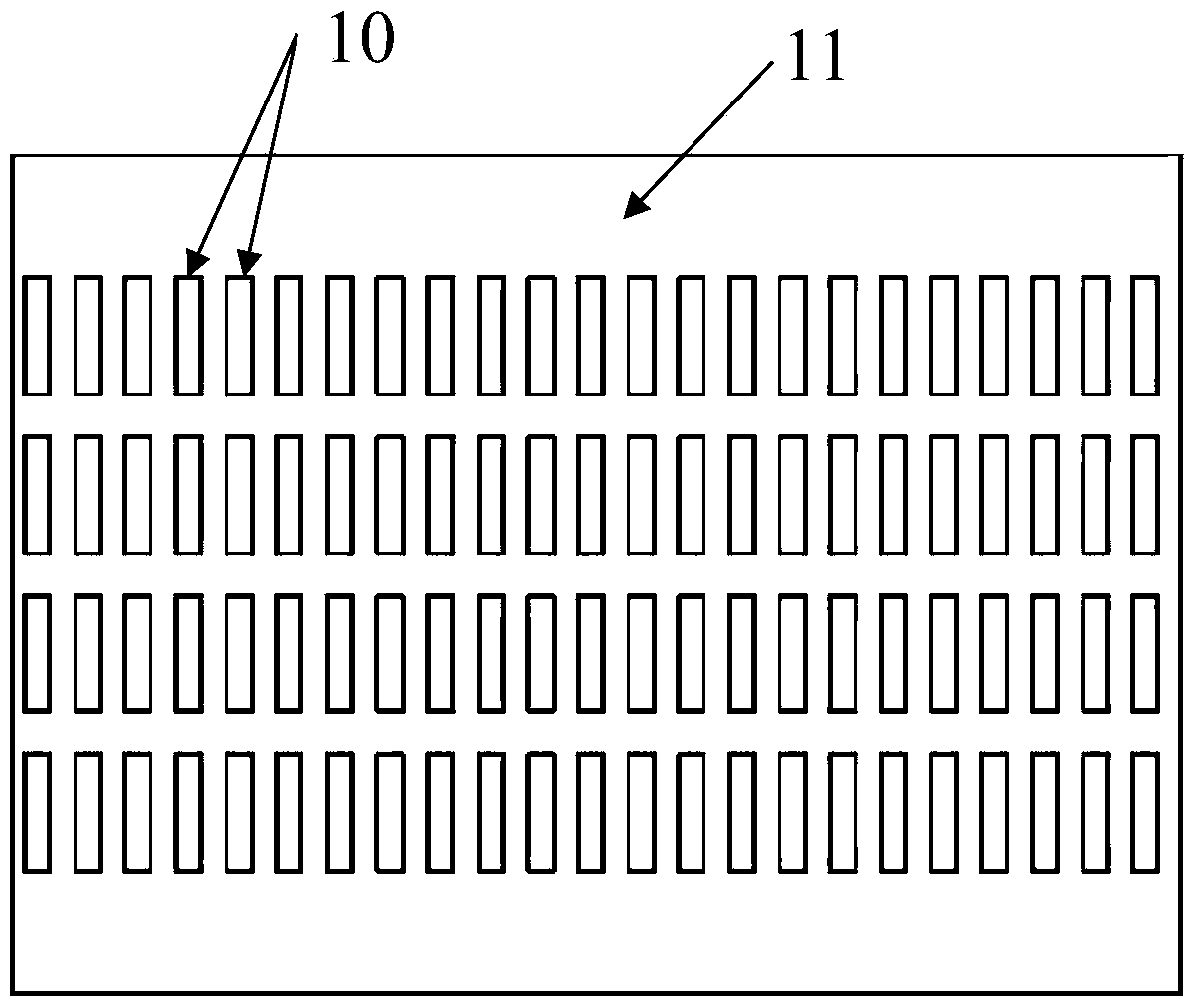

[0027] Such as figure 1 As shown, the automatic detection device for the full-surface defect of the outer circumference of the bearing roller provided by this embodiment is mainly composed of a camera 1, a conveyor belt 3 with a slot array structure, a light source 4, a rejection device 6 and a motorized drum 9. The specific detection process is as follows: First, the detection device accepts the roller production end, and the tested rolling element 2 is a bearing roller. Conveyed by the feeder to the slot array structure conveyor belt 3, the electric roller 9 drives the slot array structure conveyor belt, and the friction between the rollers and the bottom plate 12 under the conveyor belt 11 makes the rollers continuously flip through the slots 10 Below the camera, the image of the full surface of the roller is collected by the camera, and then the image is processed by the computer in real time to obtain the rele...

Embodiment 2

[0032] Example 2: Example when the rolling elements are balls

[0033] Such as Picture 10 As shown, the automatic detection device for the full-surface defect of the bearing ball provided by this embodiment is mainly composed of a camera 1, a conveyor belt 3 with a hole and slot array structure, a light source 4 and a motorized drum 9. In order to improve the detection efficiency, the conveyor belt has four S-slot channels. The active rolling diameter is larger than the driven rolling, so that the conveyor belt has a certain slope. The specific detection process is as follows: First, the detection device accepts the ball production end, and the tested rolling element 2 is a bearing ball. The feeder controls the balls to be transported to the slot array structure conveyor belt 3 one at a time, and the electric drum 9 drives the slot array structure conveyor belt to reverse. The ball uses gravity to roll freely in the hole. The roller reverses to match the friction between the b...

Embodiment 3

[0035] Example 3: Example when the rolling element is a tapered roller

[0036] Such as Picture 11 As shown, the automatic detection device for the outer surface defect of the tapered roller of the bearing provided by this embodiment is mainly composed of a camera 1, an electric turntable 17, a trapezoidal hole array structure turntable 16, a light source 4 and a base 12. Based on the characteristics of the geometric structure of the tapered roller, the tapered hollow groove annular turntable is designed to ensure the uniform rotation of the tapered roller through rotation. The specific detection process is as follows: First, the detection device accepts the tapered roller production end, and the tested rolling element 2 is a bearing tapered roller. The feeder conveys the tapered rollers to the trapezoidal hole array structure turntable 16, and the electric turntable 17 drives the trapezoidal hole array structure turntable 16 to rotate. The friction between the tapered roller a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com