Manufacturing method of wear-resistance part for concrete pump suitable for large-batch automation production

A technology of concrete pump and manufacturing method, which is applied to manufacturing tools, metal processing equipment, welding equipment, etc., can solve the problems of block collapse, hollowing out, and excessive welding seam gap.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. And the features in the embodiments can be combined with each other.

[0044] The manufacturing method of the wear-resistant parts for concrete pumps suitable for large-scale automatic production provided by the present invention is illustrated by taking the wear-resistant parts as the production examples of wear-resistant rings and wear-resistant plates respectively.

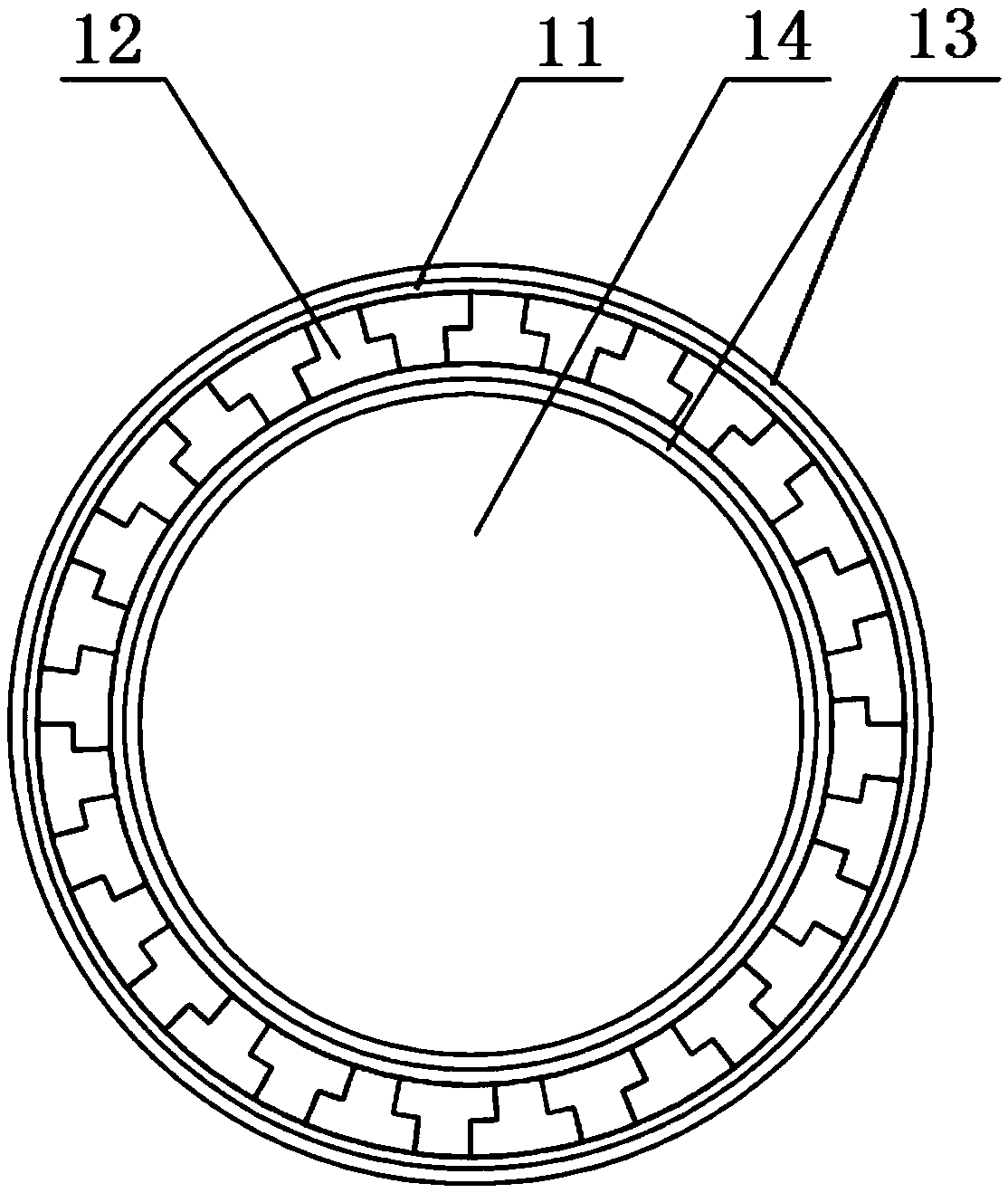

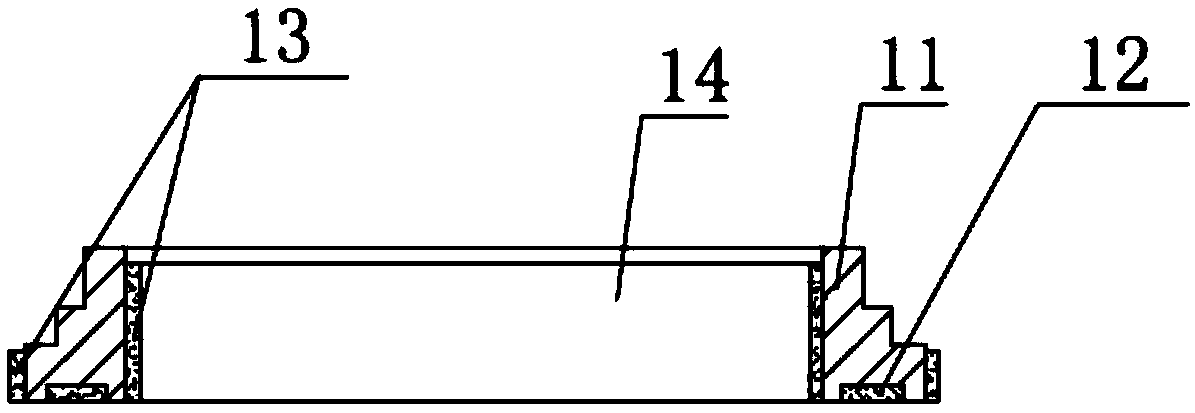

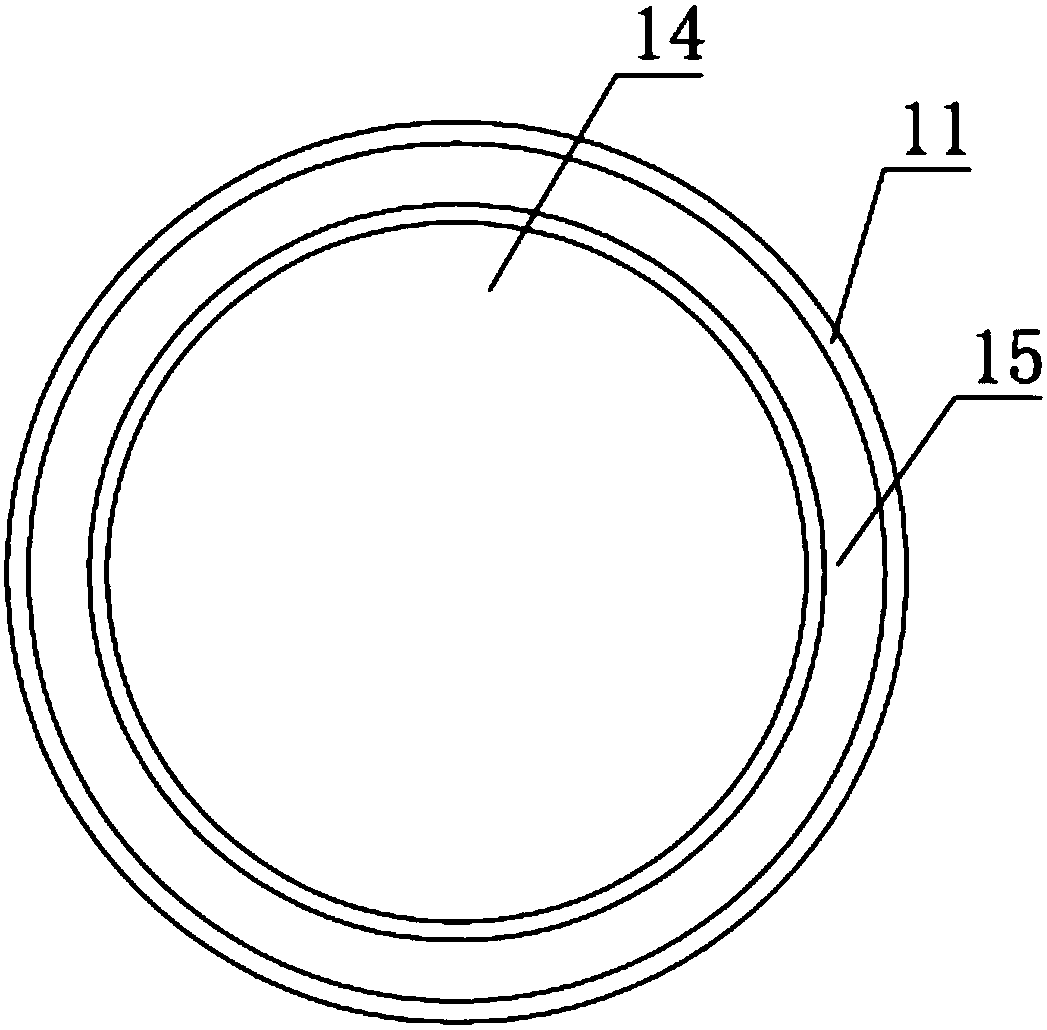

[0045] like Figure 1 to Figure 4 As shown, the wear-resistant ring includes a wear-resistant ring body 11, a hard alloy ring 12, and a surfacing wear-resistant layer 13. The wear-resistant ring body 11 is provided with a flow channel through hole 14, which is processed A cemented carbide mounting groove 15 is formed around the outside of one end of the flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com