H-shaped steel component polishing device

A steel component, I-shaped technology, applied in the direction of grinding drive device, grinding machine, grinding frame, etc., can solve the problems of time-consuming and labor-intensive, H-shaped steel components cannot be automatically polished, and achieve the effect of convenient grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

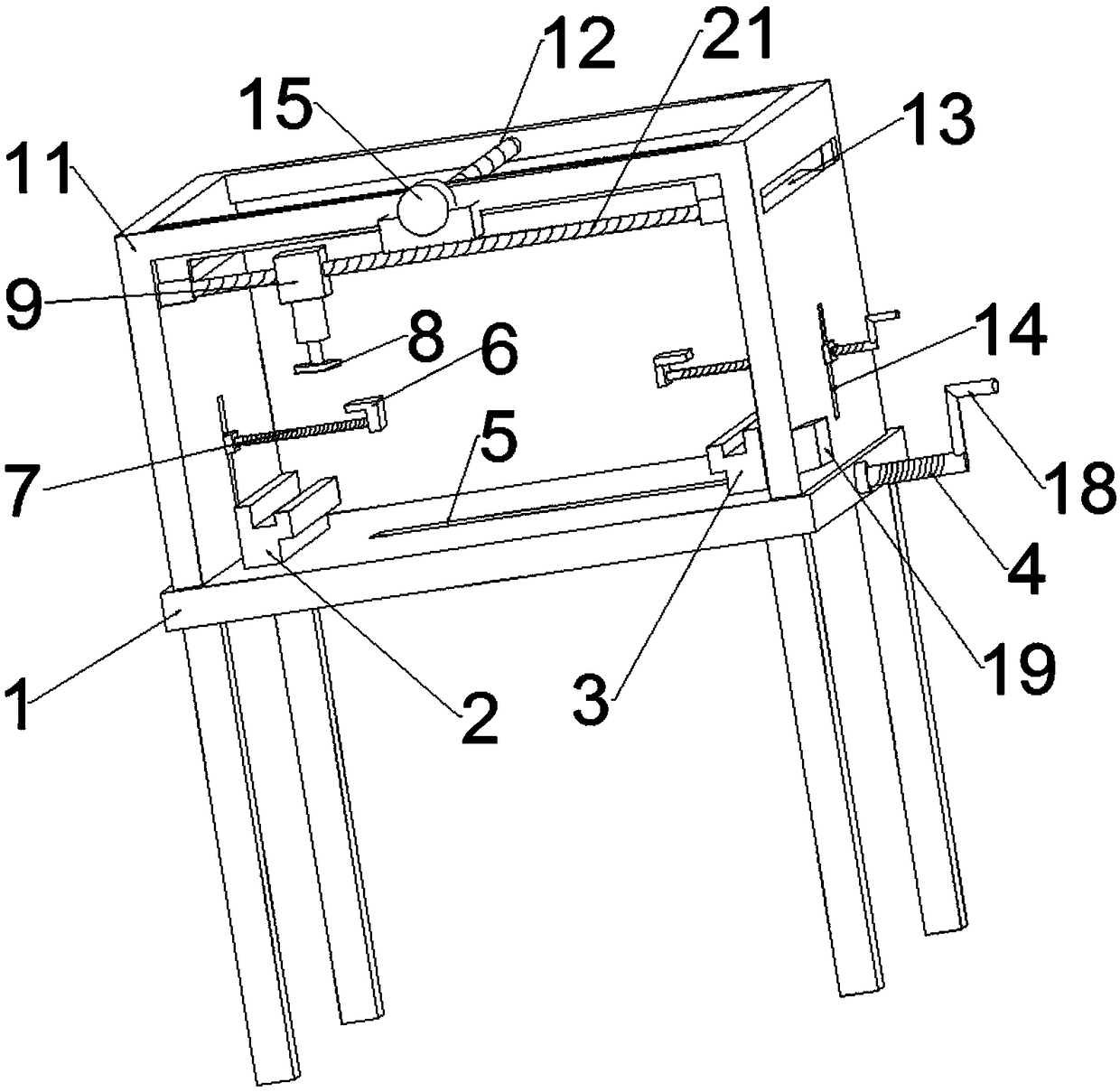

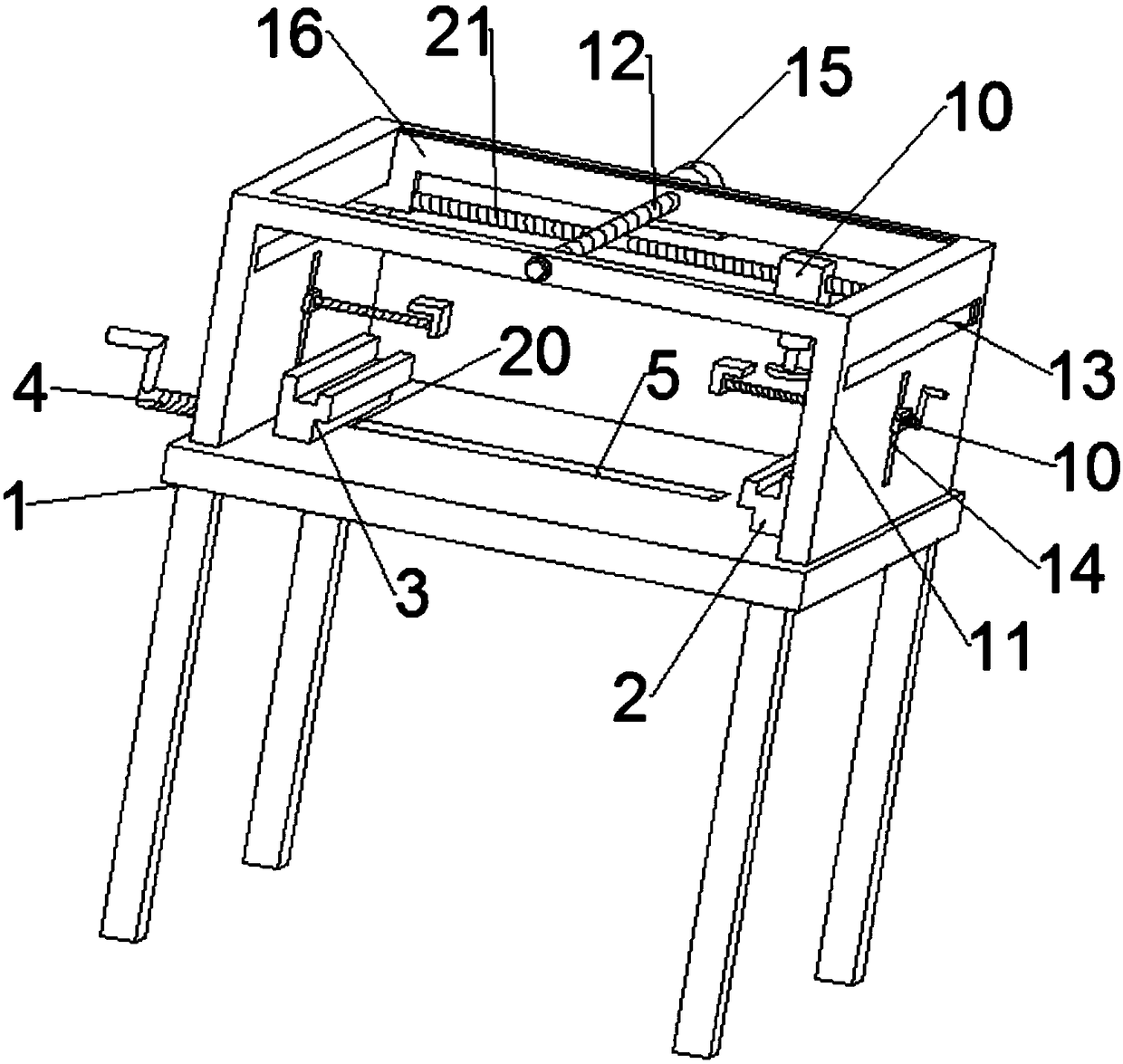

[0026] see Figure 1-4 , a H-shaped steel component grinding device, including a base plate 1, a fixed support block 2, a movable support block 3 and a PLC controller 19; the base plate 1 is provided with a transverse groove 5, and the base plate 1 is provided with a fixed support block 2 and a PLC controller 19; The movable support block 3 is fixedly connected with a slider 20 at the bottom of the movable support block 3, and the slider 20 is fixedly connected with a first screw mandrel 4, and the first screw mandrel 4 is rotatably connected with the bearings on the two side walls of the transverse groove 5. The top frame 11 is fixedly connected, and the top frame 11 is composed of side plates and horizontal plates. The middle ends of the two sets of horizontal plates of the top frame 11 are connected with a third screw rod 12 through bearing rotation, and one end of the third screw rod 12 runs through the top frame 11. The horizontal plate is fixedly connected with the outpu...

Embodiment 2

[0028] On the basis of Embodiment 1, the slider 20 is movably installed in the transverse groove 5 , which helps the first threaded rod 4 to drive the movable supporting block 3 to move. Both the fixed support block 2 and the movable support block 3 are provided with upward straight grooves and horizontal straight grooves; the fixed support block 2 and the movable support block 3 are all provided with upward straight grooves, so that the H-shaped steel member can Placed horizontally, the device can grind the web of the H-shaped steel member. Both the fixed support block 2 and the movable support block 3 are provided with straight grooves in the horizontal direction, which cooperate with the right-angled block so that the H-shaped steel member can be vertically Orientation, so that the device can grind the flange of the H-shaped steel member.

Embodiment 3

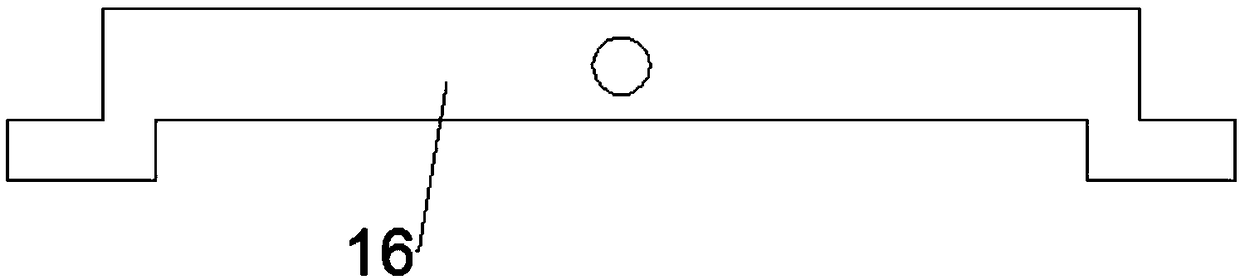

[0030] On the basis of Embodiment 1, the rotating motor 15 is fixedly mounted on the support plate connected to the outer wall of the top frame 11, so that the rotating motor 15 can conveniently drive the third screw mandrel 12 to rotate; 13 sliding connections help the slide bar 16 to drive the grinder 8 to move back and forth; one end of the second screw mandrel 7 and the first screw mandrel 4 is fixedly connected with a crank handle 18, which facilitates the movement of the movable support block 3 and the right-angle block 6, It is convenient to fix the H-shaped steel components; the outer wall of the I-shaped slider 10 is symmetrically fixed on the same horizontal line with clamping bolts 17, which is convenient for fixing the height of the right-angle block 6, so that the device is suitable for fixing H-shaped steel components of different heights; please refer to Figure 5 , the PLC controller 19 is electrically connected to the external power supply, and the PLC control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com