Method for preparing picromerite from mixed salt

A technology of langbeinite and mixed salt, which is applied in the field of salt chemical industry, can solve the problems of high energy consumption, large floor area, and low production efficiency, and achieve the effects of simple process, low energy consumption, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

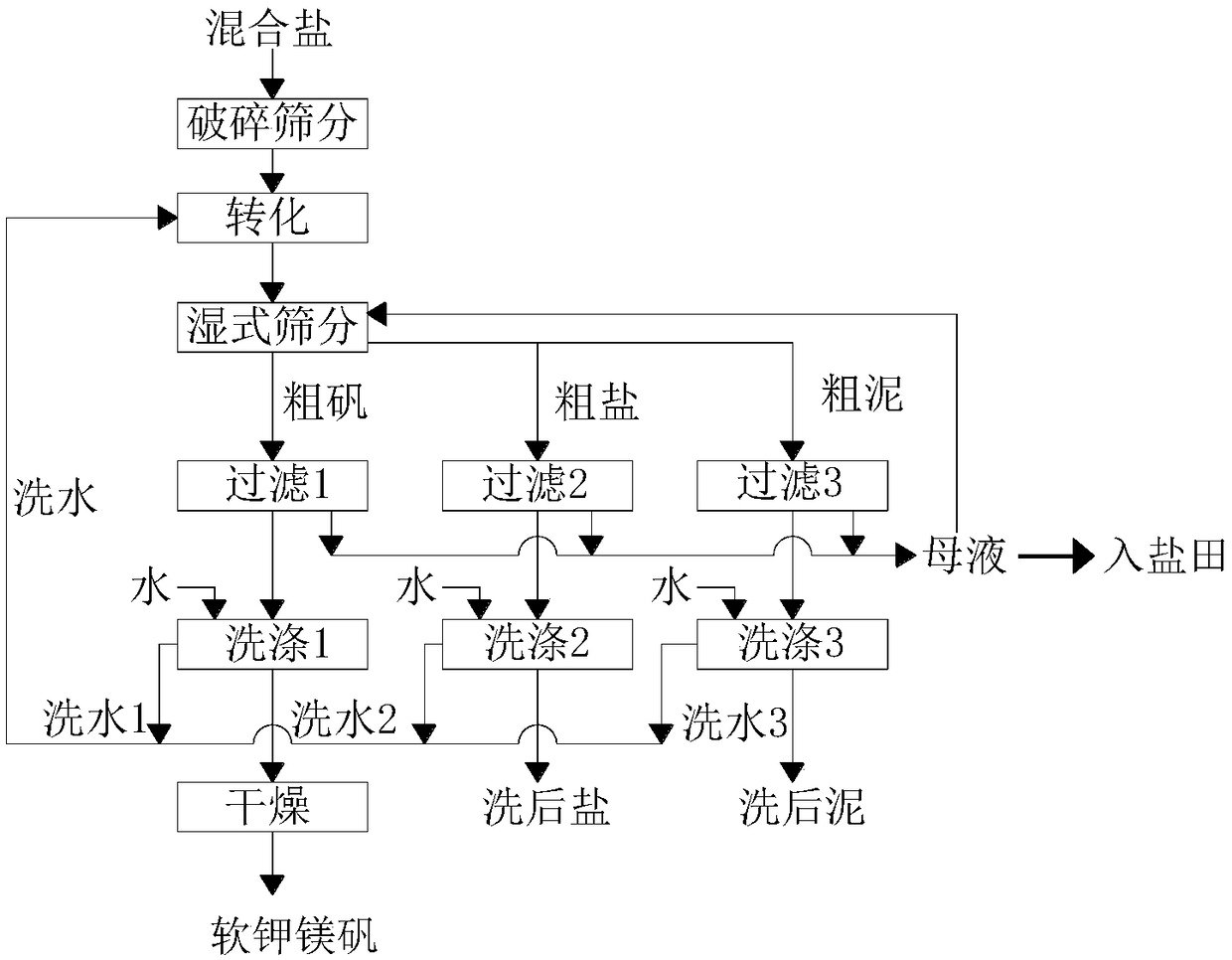

Method used

Image

Examples

Embodiment 1

[0028] The first step, crushing and screening

[0029] The 500g composition (wt%) is: K + 9.88%, Mg 2+ 8.12%, Na + 6.66%, SO 4 2- 29.52%, Cl - 21.5%, H 2 O 24.33% of the raw materials are crushed, and the mixed salt particle size is controlled at 20 mesh;

[0030] The second step, the transformation section

[0031] The raw material mixed salt and the washing water obtained through configuration are made into a slurry, and the percentage concentration of ions contained in the washing water component is: K + =2.30, Ca 2+ =0.09, Mg 2+ =1.44, SO 4 2- =6.03, Cl -=5.42, Na + =2.22, according to the water content in the washing water is 55% of the raw material mixed salt quality and puts into back washing water 374.2g, under the condition of 24 ℃, stir and transform for 30 minutes;

[0032] The third step, wet sieving, separates kobeinite

[0033] The slurry obtained after conversion is carried out to wet screening, and the mode of conversion mother liquor is sprinkle...

Embodiment 2

[0041] The first step, crushing and screening

[0042] The 1000g composition (wt%) is: K + 10.38%, Mg 2+ 8.62%, Na + 7.16%, SO 4 2- 28.36%, Cl - 25.0%, H 2 O 24.83% of the raw materials are crushed, and the mixed salt particle size is controlled at 40 mesh;

[0043] The second step, the transformation section

[0044] The raw material mixed salt and washing water are made into a slurry, and the percentage concentration of ions contained in the washing water component is: K + =2.59, Ca 2+ =0.14, Mg 2+ =1.49, SO 4 2- =6.55, Cl - =5.79, Na + = 2.39, put 775.0 g of backwash water into the raw material mixed salt, and stir for 30 minutes at 26° C.;

[0045] The third step, wet sieving, separates kobeinite

[0046] The slurry obtained after conversion is carried out to wet screening, and the mode of conversion mother liquor is sprinkled (the percentage concentration of ion contained in this conversion mother liquor is: K + =2.24%, Ca 2+ =0.16%, Mg 2+ =4.61%, Na + ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com