Crude titanium tetrachloride refining vanadium-removing method

A crude titanium tetrachloride, liquid technology, applied in the direction of titanium tetrachloride, titanium halide, etc., can solve the problems of poor conditions, highly toxic hydrogen sulfide, high labor intensity, etc., and achieve simple equipment, fast vanadium speed, and safety high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

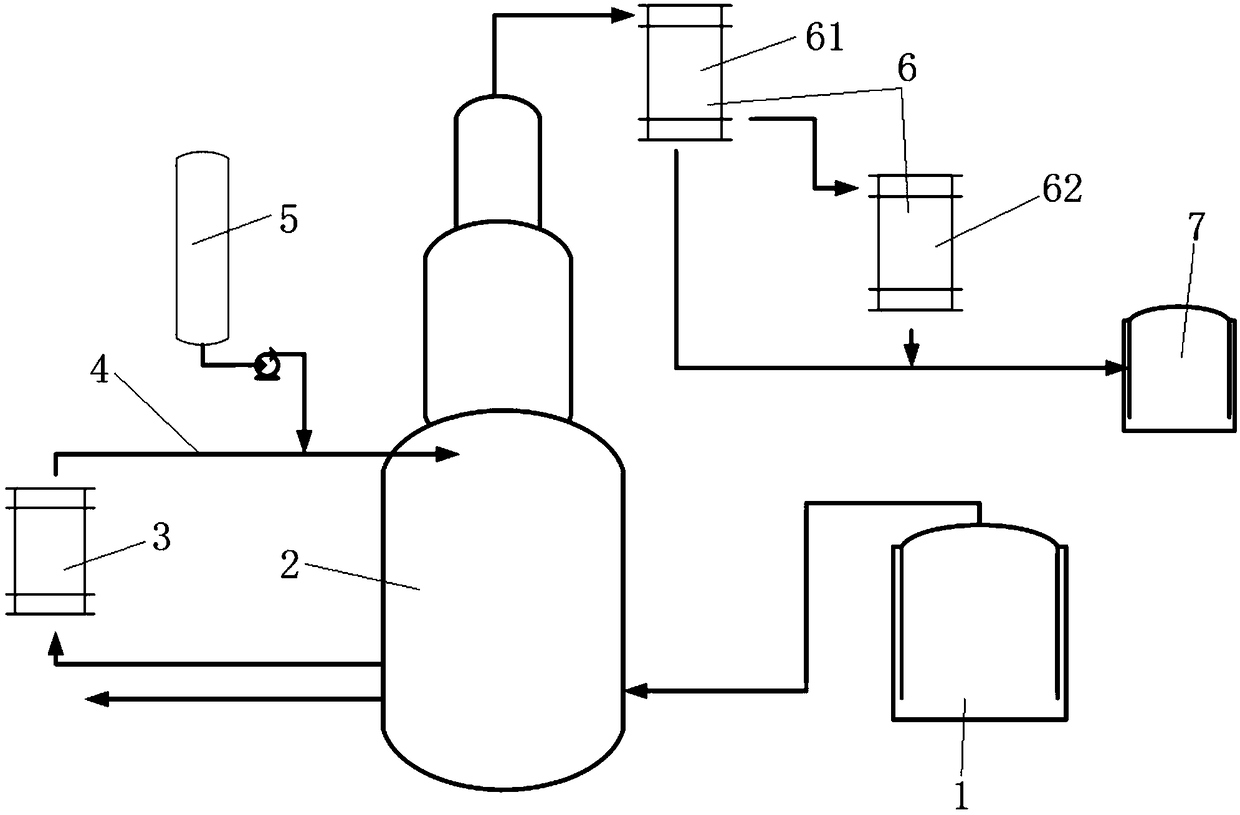

[0022] Such as figure 1 As shown, crude titanium tetrachloride refining vanadium removal equipment includes TiCl 4 Storage tank 1, refining circulation tower 2, heat exchanger 3, mixing tube 4, fatty acid storage tank 5, condensation system 6 and refined TiCl 4 storage tank7.

[0023] During production, the crude TiCl produced by the chlorination system 4 into TiCl 4 storage tank 1 cache; then pumped into the refining circulation tower 2 at a speed of 7t / h; passed into the heat exchanger 3 at a flow rate of 150t / h through the circulation pump in the tower; TiCl 4 Heating to 155°C in heat exchanger 3, pressure 0.35Mpa; high temperature and pressure TiCl in mixing tube 4 4 The liquid is mixed and reacted with the fatty acid from the fatty acid storage tank 5, and the reacted mixture enters the refining circulation tower 2; about 6.5t / h of TiCl 4 The liquid is vaporized into TiCl 4 Steam, this part of the steam enters the condensation system 6 through the top sieve plate, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com