Preparation method of full-light-control azobenzene thin film surface reversible wrinkle microstructure

A technology of optically controlling azobenzene and azobenzene, which is applied in the field of smart surface preparation to achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing a reversible wrinkle microstructure on the surface of an all-optical control azobenzene film, comprising the following steps:

[0026] Step 1, mix the PDMS prepolymer and crosslinking agent Sylgard 184 (purchased from Dow Corning, USA) at a mass ratio of 10:1, and fully stir with a glass rod to form a uniform prepolymer; put the above prepolymer in circulating water After degassing in a multi-purpose vacuum pump for 1 hour, pour it into a watch glass; heat it at 70°C for 4 hours to cure; obtain a PDMS soft substrate;

[0027] Step 2. The PDMS soft substrate obtained in step 1 is subjected to oxygen plasma surface activation treatment, and then spin-coated with 2wt% PDO 3 THF solution (spin-coating parameters: 3000rpm, 40s), degassed in a vacuum pump to remove residual organic solvents, to obtain PDMS / PDO 3 Soft and hard composite system.

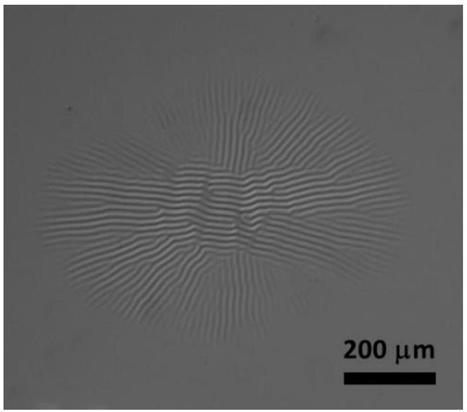

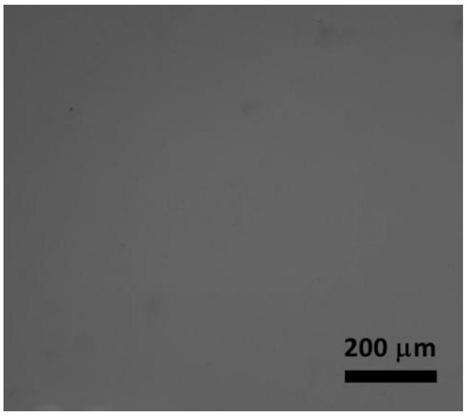

[0028] Step 3, the PDMS / PDO obtained in step 2 3 Composite system at 2.46W / cm 2 450nm laser irradiation f...

Embodiment 2

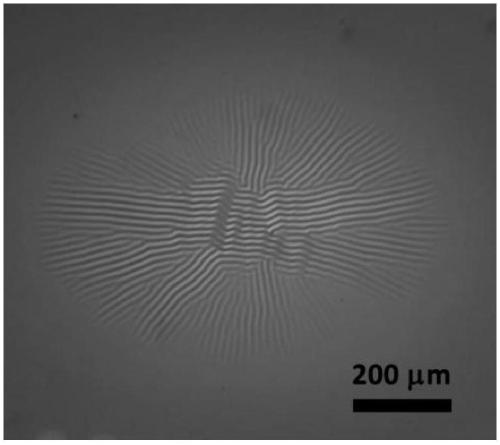

[0032] A method for preparing a reversible wrinkle microstructure on the surface of an all-optical control azobenzene film, the preparation process of which is basically the same as in Example 1, except that the 2.46W / cm 2 450nm laser irradiation 5s changed to 410mW / cm -2 Irradiated under white light for 60s, a maze-like surface wrinkle pattern is obtained, such as Figure 5 As shown in the light microscope diagram; 45mW / cm in step 4 2 450nm laser irradiation 10s changed to 15mW / cm -2 Irradiate under white light for 120s to regain a smooth azobenzene film, such as Image 6 shown in the light microscope diagram. In step 5, the number of repeated wrinkling / wrinkling is changed from 20 times to 10 times, and the surface wrinkle pattern obtained in step 3 for the 10th time is as follows: Figure 7 As shown in the light microscope image, the wrinkle-free pattern on the surface obtained in step 4 for the 10th time is as follows Figure 8 shown in the light microscope diagram. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com