Electroplating brush device

A technology of electroplating brushes and fixing devices, applied in plating baths, electrolytic processes, electrolytic components, etc., can solve problems such as bending, affecting the uniformity of the coating layer, affecting the quality of the workpiece, etc., to avoid manual interference, reduce labor intensity, and ensure quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

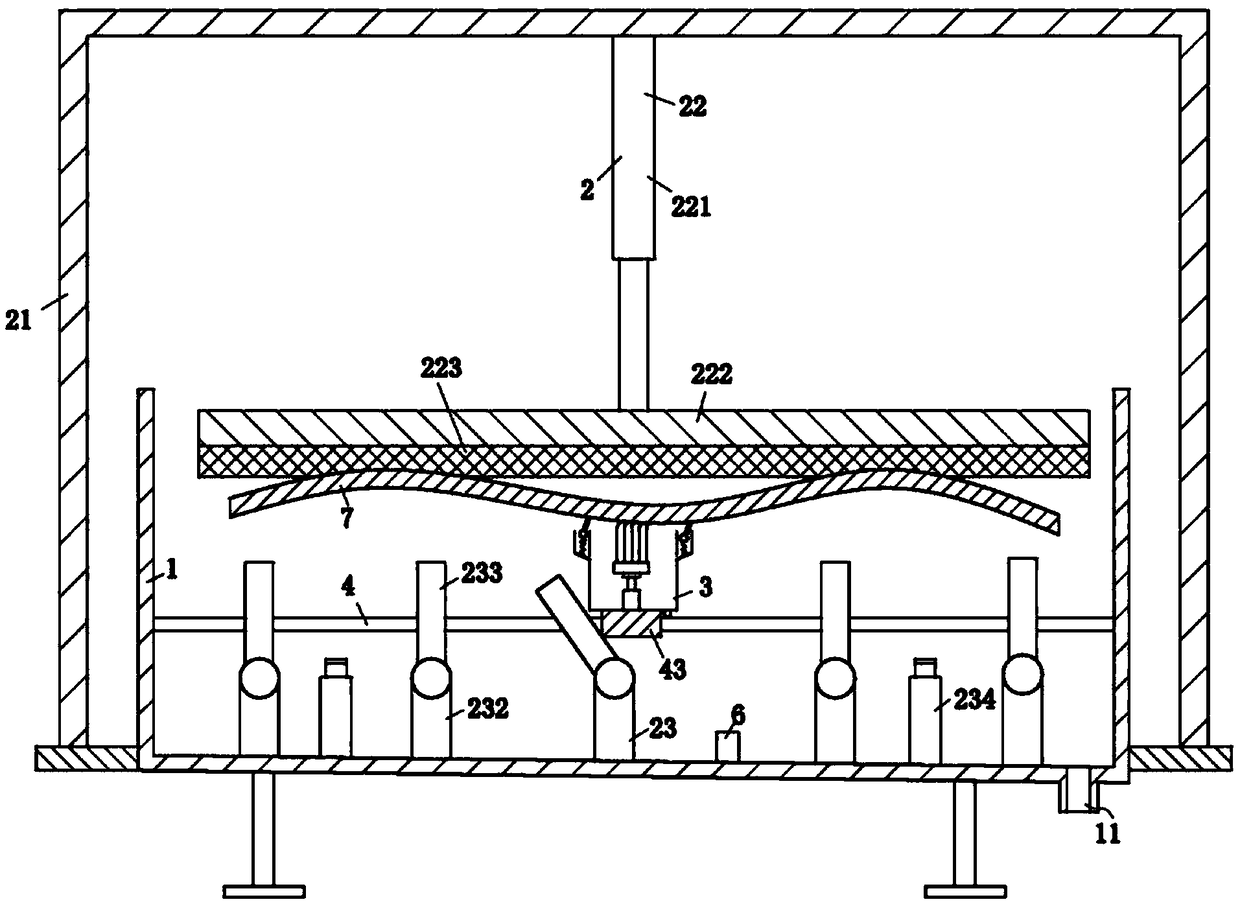

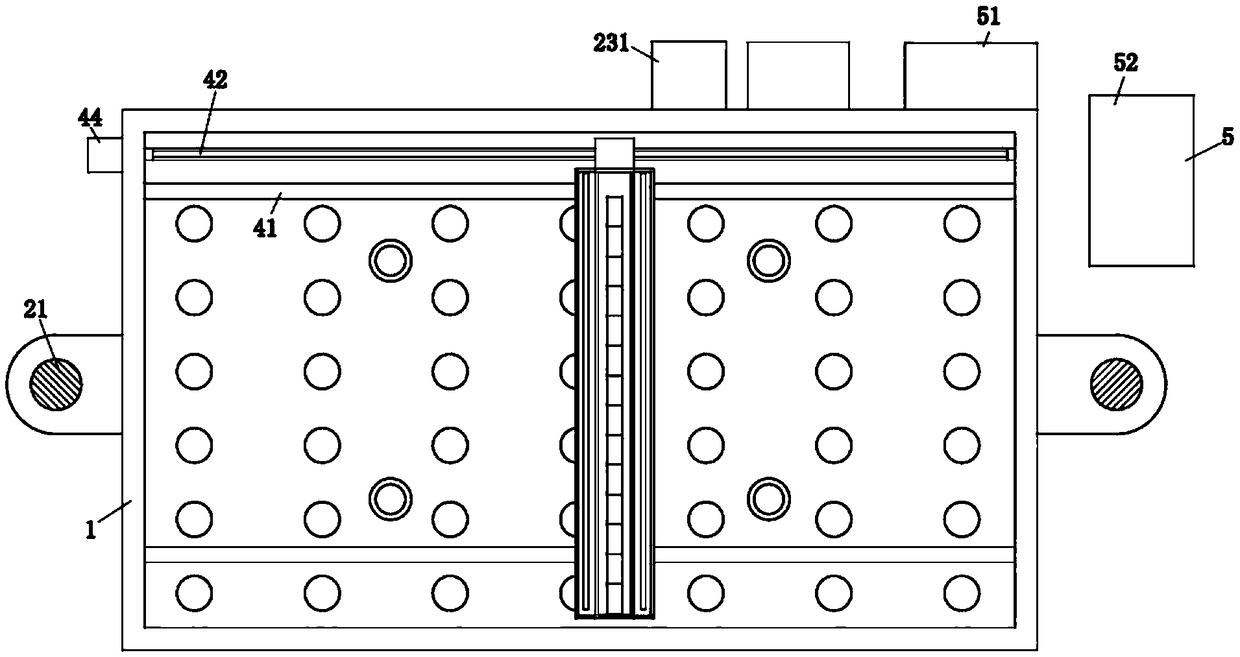

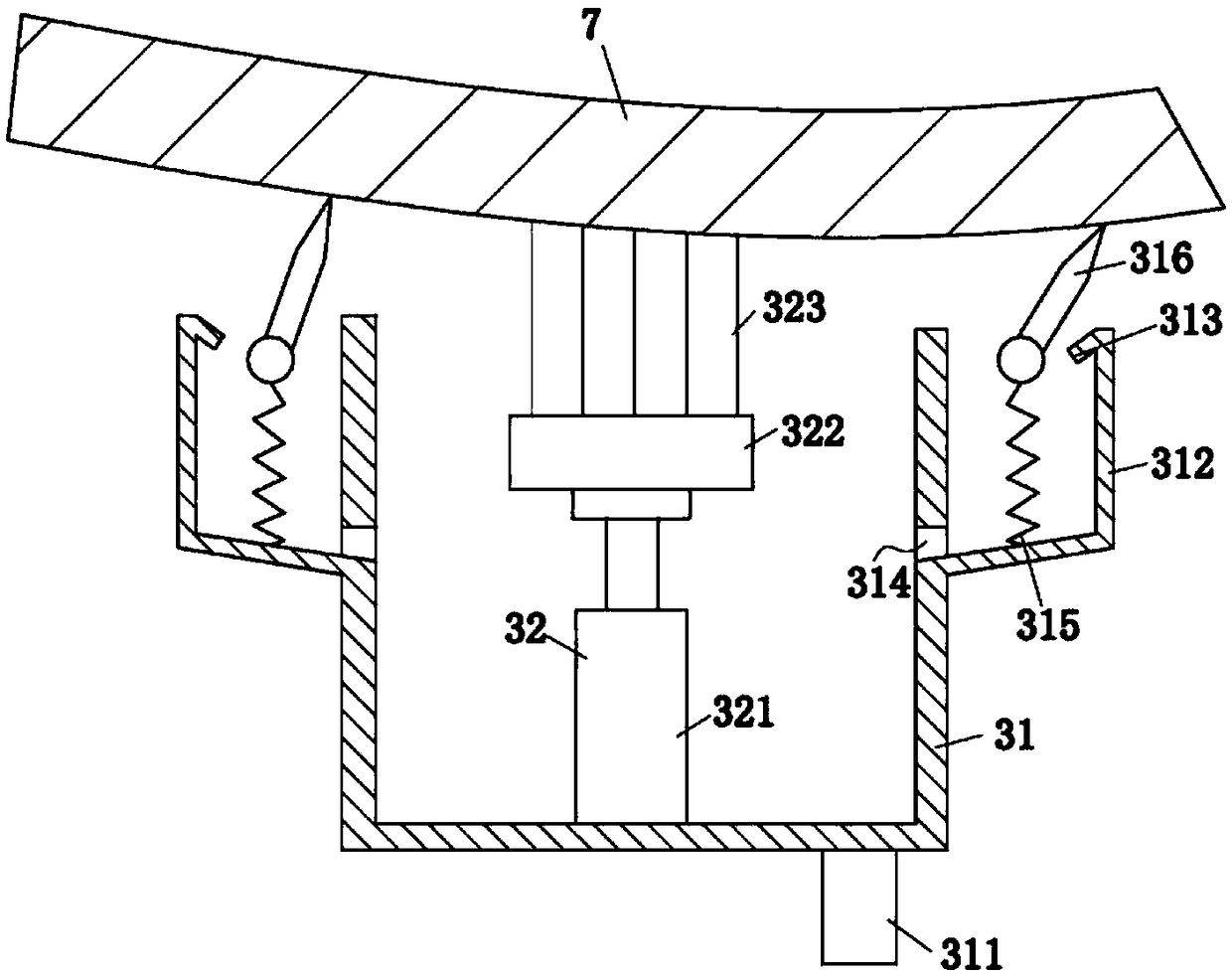

[0033] As an embodiment of the present invention, the workpiece fixing device 2 includes a support frame 21, a push unit 22 and a blower unit 23; the push unit 22 is installed above the painting tank 1 through the support frame 21, and the blower unit The unit 23 is installed on the bottom of the painting tank 1, and the pushing unit 22 and the blowing unit 23 cooperate with each other to realize the fixing of the workpiece 7; wherein, the pushing unit 22 includes a telescopic rod 221, a top plate 222 and a silicone pad 223, and the telescopic The rod 221 is fixedly connected with the support frame 21, the top plate 222 is connected with the telescopic rod 221 by bolts, the silica gel pad 223 is fixed on the lower surface of the top plate 222, and the silica gel pad 223 directly contacts the workpiece 7, and the silica gel pad 223 can hold the workpiece 7 on the one hand. Carrying out position limiting, on the other hand, can prevent the workpiece 7 from being scratched. The b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com