Preparation method of filler for improving antibacterial property of artificial textile fibers

A textile fiber, antibacterial technology, applied in the field of textile fiber processing, can solve the problems of poor antibacterial performance, affecting function and effect, etc., and achieve the effect of good durability, reasonable matching and high affinity and compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

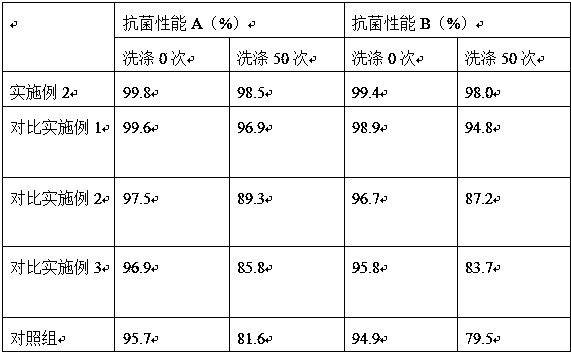

Examples

Embodiment 1

[0025] A preparation method for improving the antibacterial properties of man-made textile fibers, comprising the steps of:

[0026] (1) Immerse the montmorillonite in the acid solution for 5 minutes, filter it out and rinse it with water until neutral, then put it into the calciner for calcination for 1 hour;

[0027] (2) Mix the montmorillonite, nano-silver particles, sodium pyrophosphate, fatty alcohol polyoxyethylene ether, and deionized water after step (1) according to the weight ratio of 10:0.5:3:5:280 into the In the mixing tank, after high-speed stirring treatment for 1 hour, the mixed solution A was prepared for use;

[0028] (3) Put the corn stalks into the steam explosion tank for steam explosion treatment, and take them out for later use;

[0029] (4) Immerse the corn stalks treated in step (3) into the mixed solution A obtained in step (2), and take out the corn stalks after ultrasonic treatment for 1.5 hours;

[0030] (5) Put the corn stalks treated in step (4...

Embodiment 2

[0042] A preparation method for improving the antibacterial properties of man-made textile fibers, comprising the steps of:

[0043] (1) Immerse the montmorillonite in the acid solution for 6 minutes, filter it out and rinse it with water until neutral, then put it into the calciner for calcination for 1.5 hours;

[0044] (2) Mix the montmorillonite, nano-silver particles, sodium pyrophosphate, fatty alcohol polyoxyethylene ether, and deionized water after step (1) according to the weight ratio of 13:0.8:4:6:290. In the mixing tank, after 1.3 hours of high-speed stirring treatment, the mixed solution A was prepared for use;

[0045] (3) Put the corn stalks into the steam explosion tank for steam explosion treatment, and take them out for later use;

[0046] (4) Immerse the corn stalks treated in step (3) into the mixture A obtained in step (2), and take out the corn stalks after ultrasonic treatment for 1.8 hours;

[0047] (5) Put the corn stalks treated in step (4) into a c...

Embodiment 3

[0059] A preparation method for improving the antibacterial properties of man-made textile fibers, comprising the steps of:

[0060] (1) Immerse the montmorillonite in the acid solution for 7 minutes, filter it out and rinse it with water until neutral, then put it into the calciner for calcination for 2 hours;

[0061] (2) Mix the montmorillonite, nano-silver particles, sodium pyrophosphate, fatty alcohol polyoxyethylene ether, and deionized water after step (1) according to the weight ratio of 15:1:5:7:300 into the In the mixing tank, after 1.5 hours of high-speed stirring treatment, the mixed solution A was prepared for use;

[0062] (3) Put the corn stalks into the steam explosion tank for steam explosion treatment, and take them out for later use;

[0063] (4) Immerse the corn stalks treated in step (3) into the mixed solution A obtained in step (2), and take out the corn stalks after ultrasonic treatment for 2 hours;

[0064] (5) Put the corn stalks treated in step (4)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com