Vertical type sintering furnace with movable furnace bottom

A sintering furnace and movable technology, applied in the field of heating furnaces, can solve the problems of uneven shrinkage, high heating temperature, material cracking, etc., and achieve the effects of avoiding radiation shadow effects, improving temperature uniformity, and saving energy costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and technical effect of the present invention clearer, the present invention will be further described below in conjunction with specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

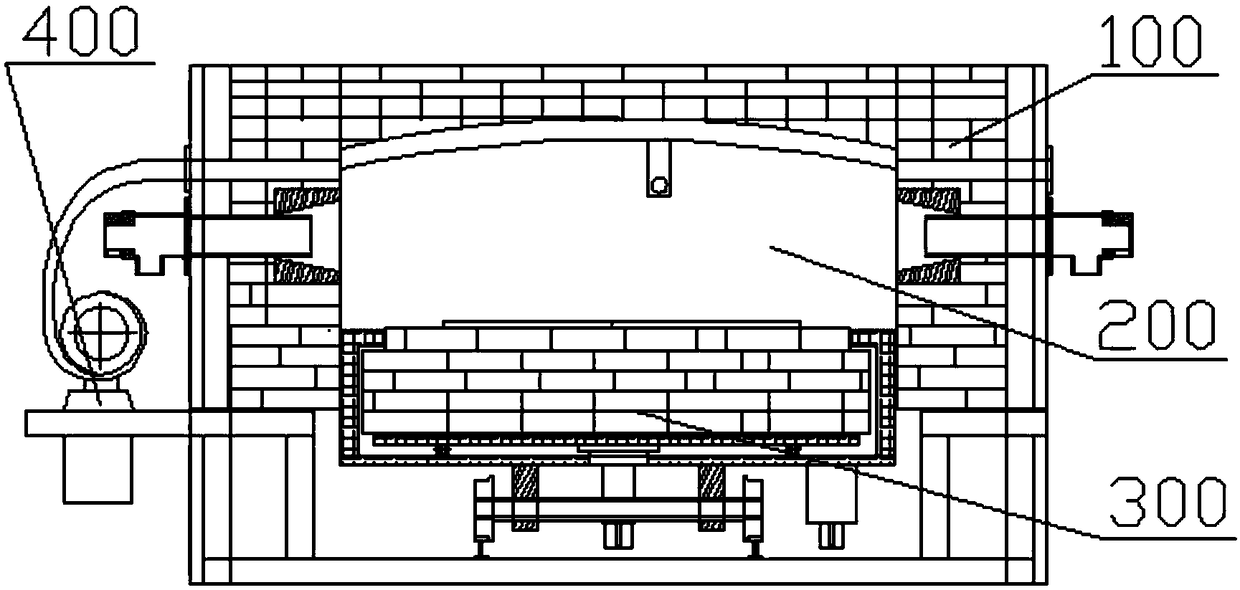

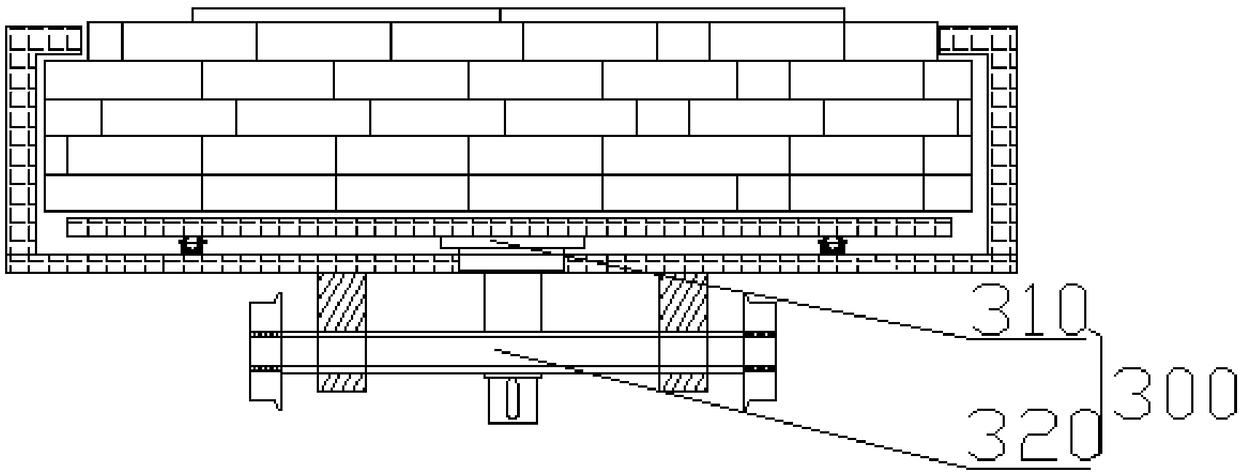

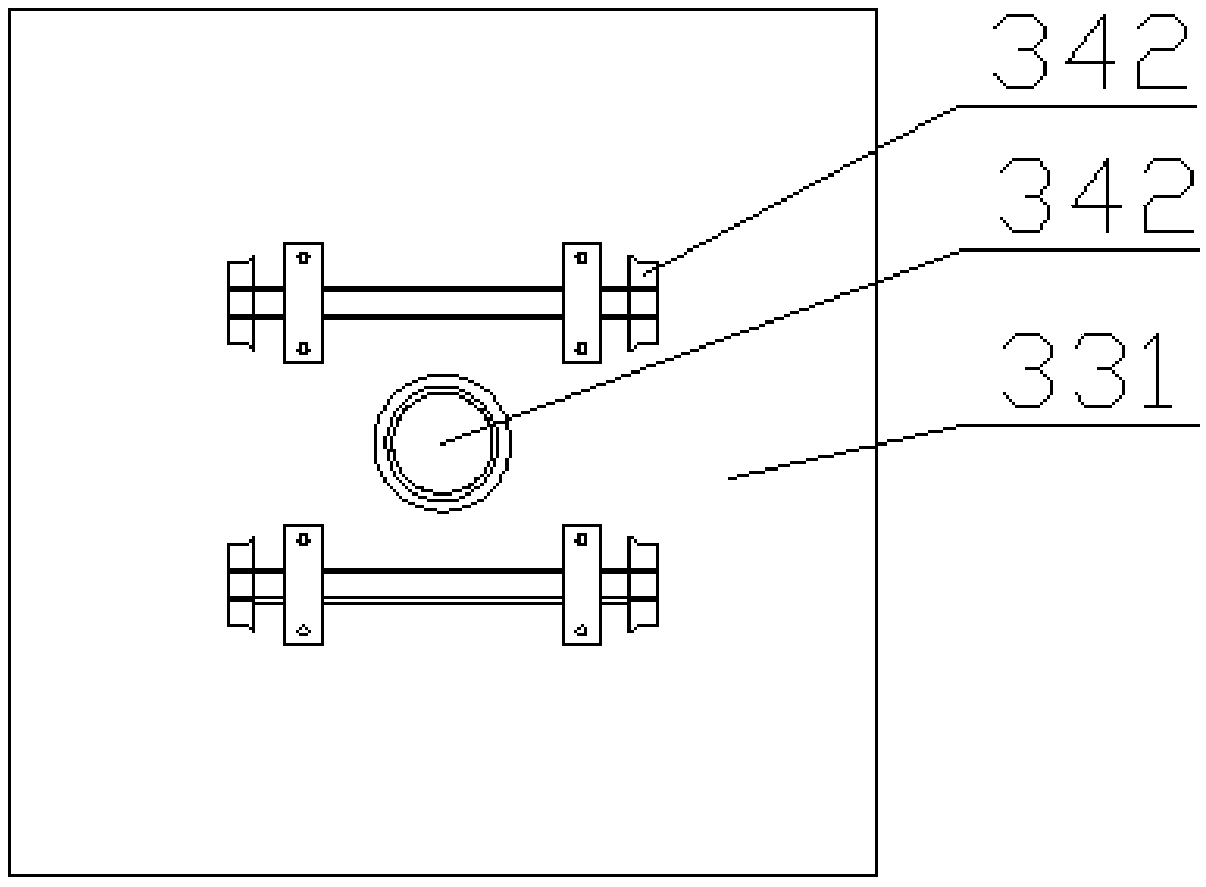

[0027] refer to figure 1 and figure 2 As shown, a vertical sintering furnace with a movable furnace bottom includes a furnace body 100, at least one heating nozzle 111 disposed on the side wall of the furnace body 1, a furnace chamber 200 disposed within the furnace body, and a furnace body disposed at the bottom of the furnace chamber. Furnace bottom 300; in this embodiment, a rotating mechanism 310 and a moving mechanism 320 connected thereto are provided below the furnace bottom 300, and the rotating mechanism 310 can drive the furnace bottom 300 to be adjustable in the furnace 200 The moving mechanism 320 supports t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com