Testing method for prolonging cycle life of lithium iron phosphate power lithium battery

A technology of cycle life and lithium iron phosphate, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of short cycle life and long test time of lithium batteries, reduce polarization, shorten charging time, speed up Effects of Power Decay and Lifetime Decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

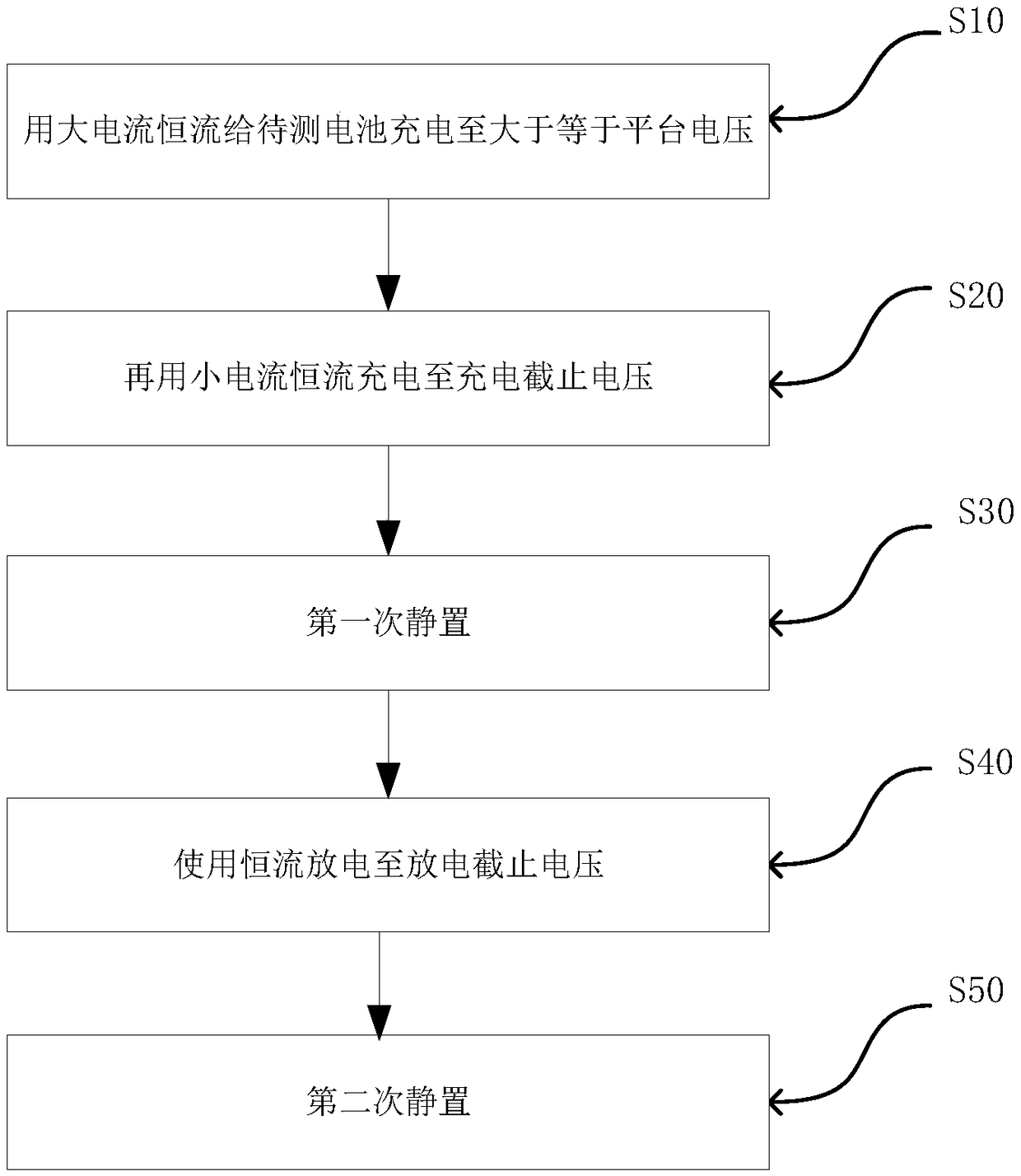

[0030] At room temperature of 25°C, the cycle life test of a cylindrical lithium iron phosphate battery with a rated capacity of 12Ah is carried out according to the following steps: 1) 1C constant current charging to 3.5V, 0.5C constant current charging to 3.65V (charging time is about 1h16min ); 2) Stand still for 10min; 3) 1C constant current discharge to 2.00V; 4) Stand still for 10min. The capacity retention rate in the cycle was recorded, and the test results are shown in Table 1.

Embodiment 2

[0032] At room temperature of 25°C, the cycle life test of a cylindrical lithium iron phosphate battery with a rated capacity of 12Ah is carried out according to the following steps: 1) 0.8C constant current charging to 3.55V, 0.5C constant current charging to 3.65V (charging time is about 1h23min); 2) Stand still for 10min; 3) 1C constant current discharge to 2.00V; 4) Stand still for 10min. The capacity retention rate in the cycle was recorded, and the test results are shown in Table 1.

Embodiment 3

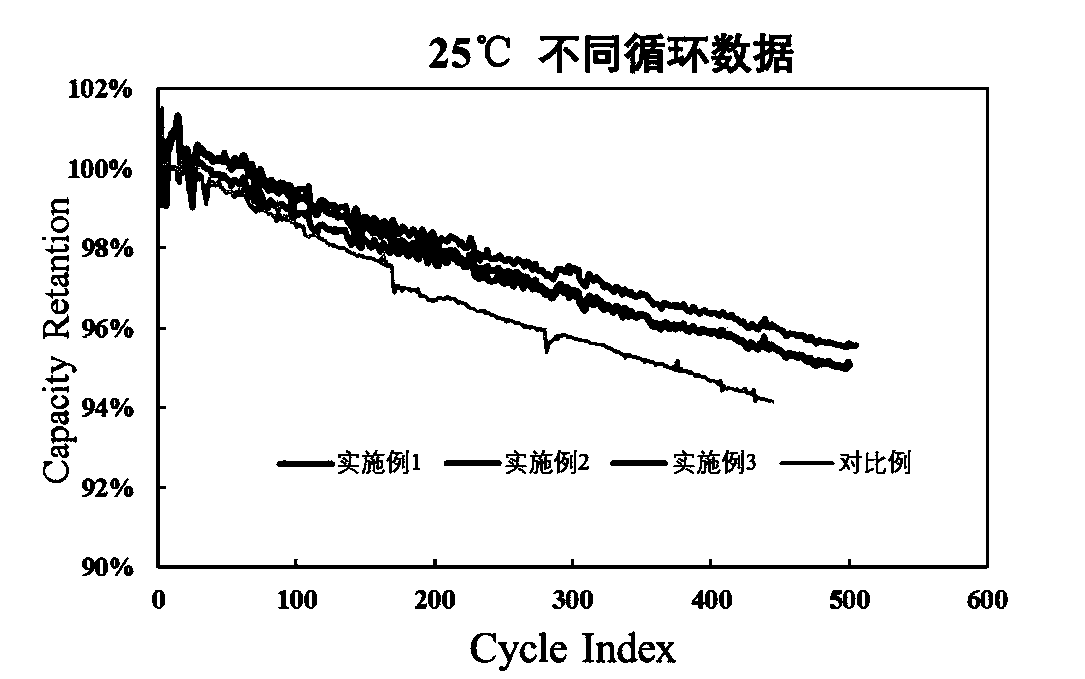

[0034] At room temperature of 25°C, the cycle life test of a cylindrical lithium iron phosphate battery with a rated capacity of 12Ah is carried out according to the following steps: 1) 1C constant current charge to 3.45V, 0.5C constant current charge to 3.55V, 0.2C constant current Charge to 3.65V (charging time is about 1h44min); 2) Stand still for 10min; 3) Discharge at 1C constant current to 2.00V; 4) Stand still for 10min. Record the capacity retention rate in the cycle, the test steps are shown in Table 1, and the cycle data are as follows figure 1 shown.

[0035] Comparison / Example

Cycle test charging steps

comparative example

0.5C constant current charging to 3.65V, constant voltage charging to 0.05C

Example 1

1C constant current charging to 3.5V, 0.5C constant current charging to 3.65V

Example 2

0.8C constant current charging to 3.55V, 0.5C constant current charging to 3.65V

Example 3

1C constant current charge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com