Coupling numerical simulation method of seepage-damage-stress for coal and rock mass water injection

A numerical simulation, coal-rock mass technology, applied in the field of mine rock mechanics, can solve problems such as the inability to reproduce the simulation from a macro perspective, difficult coal mass fracture, and the inability to accurately describe the seepage process and moisture increment data, etc., and achieve a small number of units , reduced likelihood, data preparation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

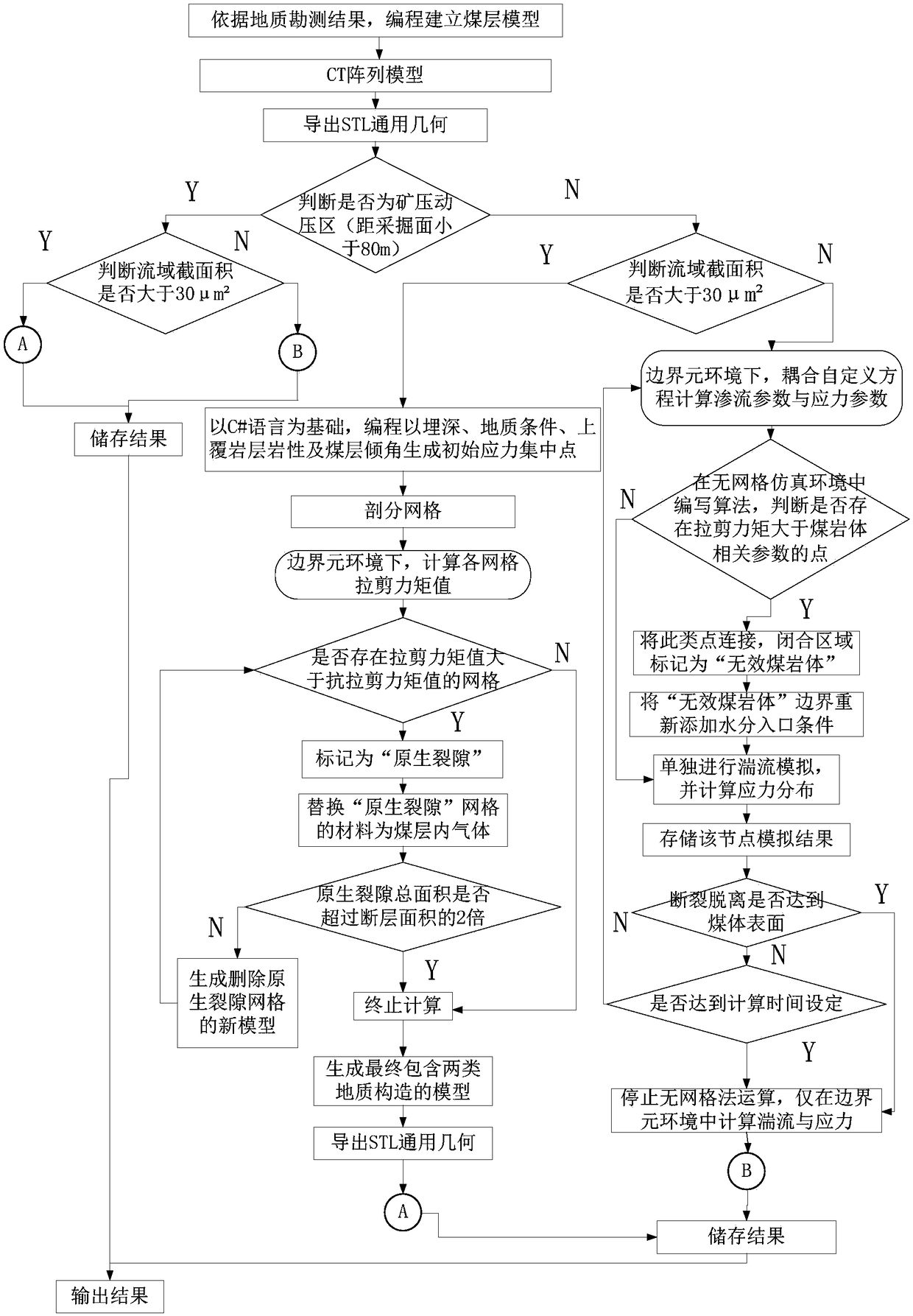

Method used

Image

Examples

Embodiment 1

[0122] Step 1 is to establish a coal-rock mass model including faults based on geological survey results, which specifically includes the following steps:

[0123] (1) Under the Cartesian coordinate system, the geometric model of the coal body is established according to the height of the water injection coal seam, the length of the strike and the length of the dip, and the model dimension is three-dimensional;

[0124] (2) Among them, six parameters of "fault starting point", "fault end point", "fault turning point", "azimuth difference", "drop", and "dip angle" are reserved for user input.

[0125] (3) Then export STL general geometry.

[0126] Step 2CT array model, which specifically includes the following steps:

[0127] (1) The nanoVoxel-2000 series-X-ray three-dimensional microscope with an accuracy of 0.5 μm was used to conduct scanning experiments on long-flame coal, and combined with the FDK three-dimensional reconstruction algorithm to construct a three-dimensional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com