Composite grounding cable

A composite grounding and cable technology, applied in the direction of cables, insulated cables, connecting contact materials, etc., can solve the problem that the grounding cable is not easy to be corroded, and achieve the effect of good grounding effect, good corrosion resistance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

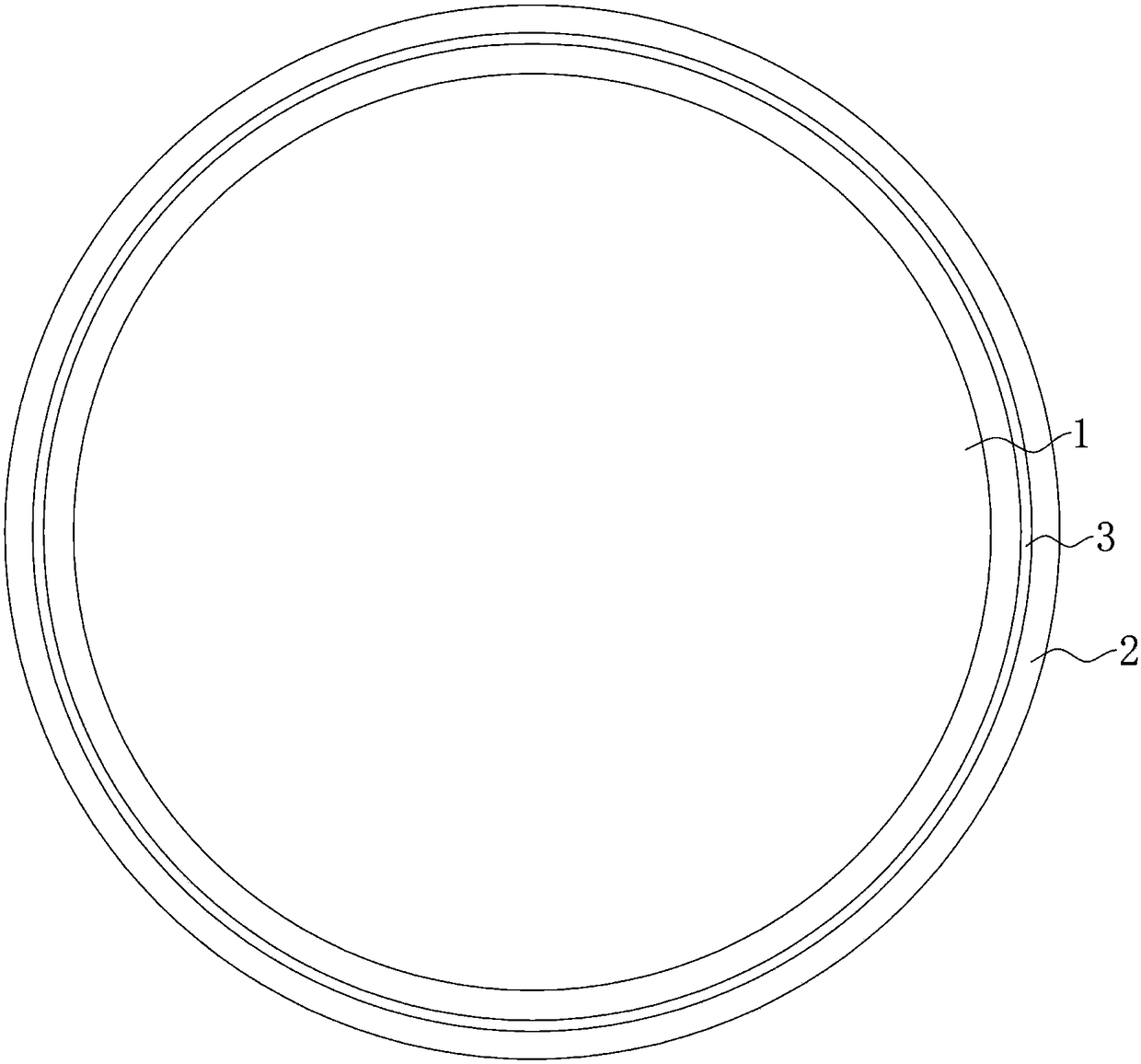

[0027] Such as figure 1 As shown, the present invention provides a composite grounding cable, which includes a grounding cable 1 and a first anti-corrosion layer 2 coated on the outside of the grounding cable 1 . The grounding cable 1 is made of simple metal or alloy metal. In order to improve the corrosion resistance of the conductor, many existing grounding bodies usually use graphite and other non-metallic materials with good corrosion resistance to weave the grounding body. The ability to withstand high-current short-circuit is poorer than that of metal conductors, so the grounding cable 1 of this scheme is selected as a metal body with a diameter ranging from 5-10mm, and the first anti-corrosion layer 2 is extruded on the outer wall of the grounding cable 1 The conductive layer on the top makes the inside of the first anti-corrosion layer 2 form a seal without leakage, so that the grounding cable 1 is completely isolated from the outside world, preventing it from being ox...

Embodiment 2

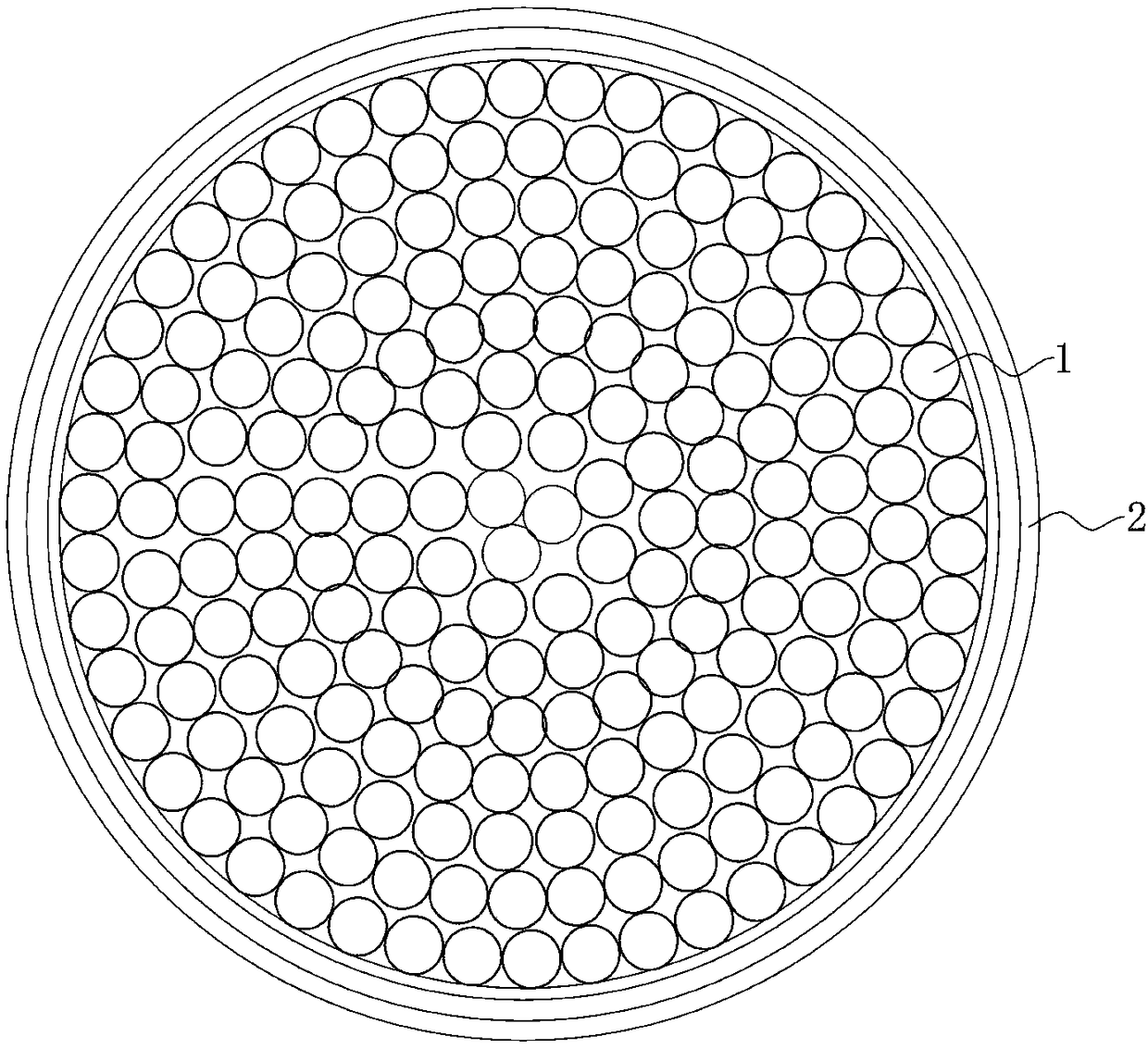

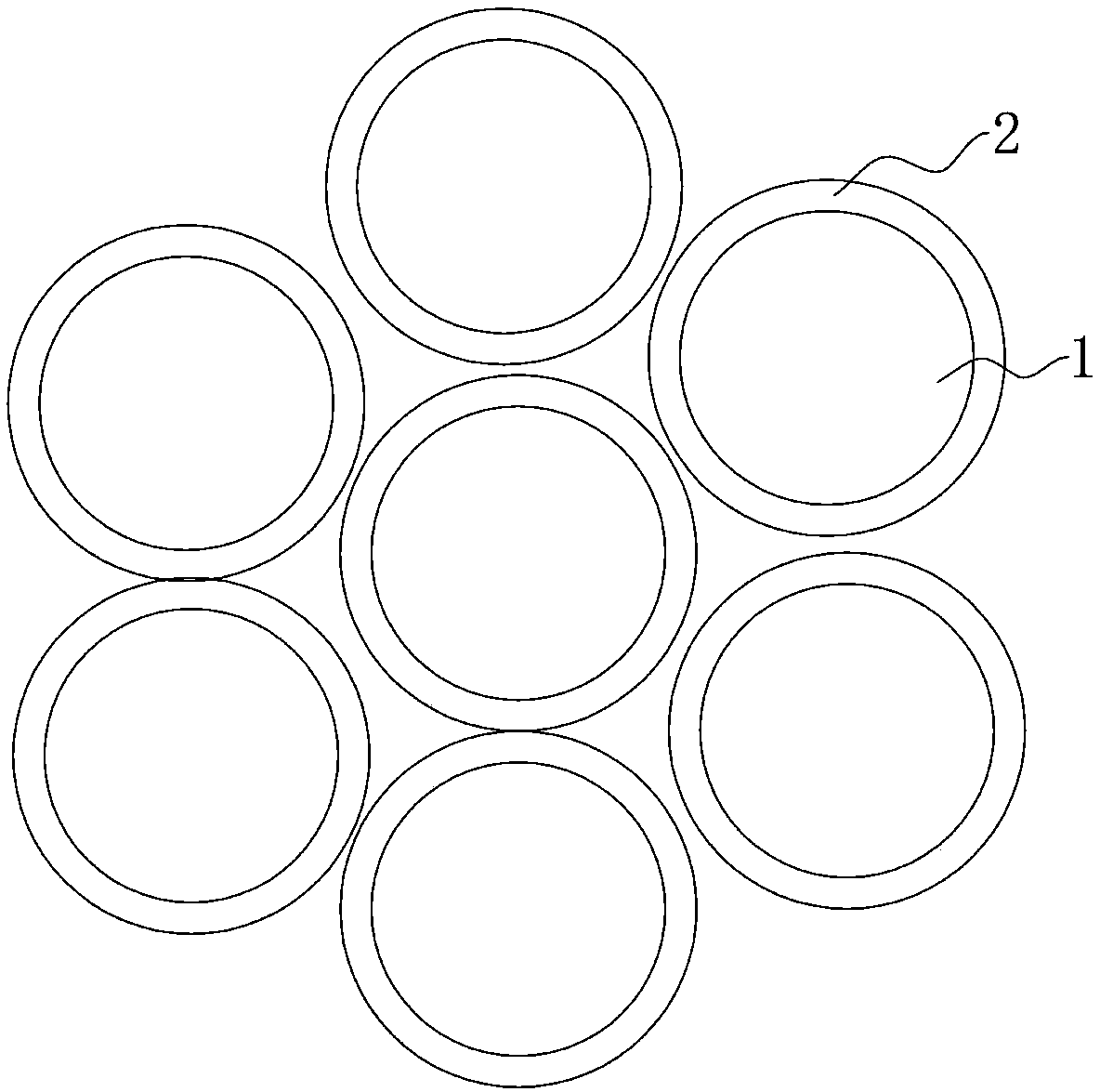

[0029] The difference from Embodiment 1 is that the grounding cable 1 is formed by a tight bundle of multiple metal wires, wherein the multiple metal wires are distributed in a linear array or a circular array, and the twisted structure of multiple metal wires makes each The copper core wires are tightly wound and arranged stably to obtain a relatively ideal overall mechanical strength and stable electrical properties of the cable; and to maintain a certain flexibility of the cable to meet the actual needs of various laying constructions and meet the needs of multiple electrical equipment. For equipotential connection, the number and diameter of metal wires can be designed and adjusted according to specific usage conditions. Similarly, the material of metal wires can also be designed as aluminum core wire, steel core wire, etc. according to the electrical performance index of grounding. Metal core wire. A second anti-corrosion layer 4 is also plated on the outer wall of each w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com