A solar cell crystal silicon insertion device

A technology of solar cells and crystalline silicon, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as poor quality, damage to single crystal silicon wafers, and low efficiency, and achieve the effects of improving stability, improving protection, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

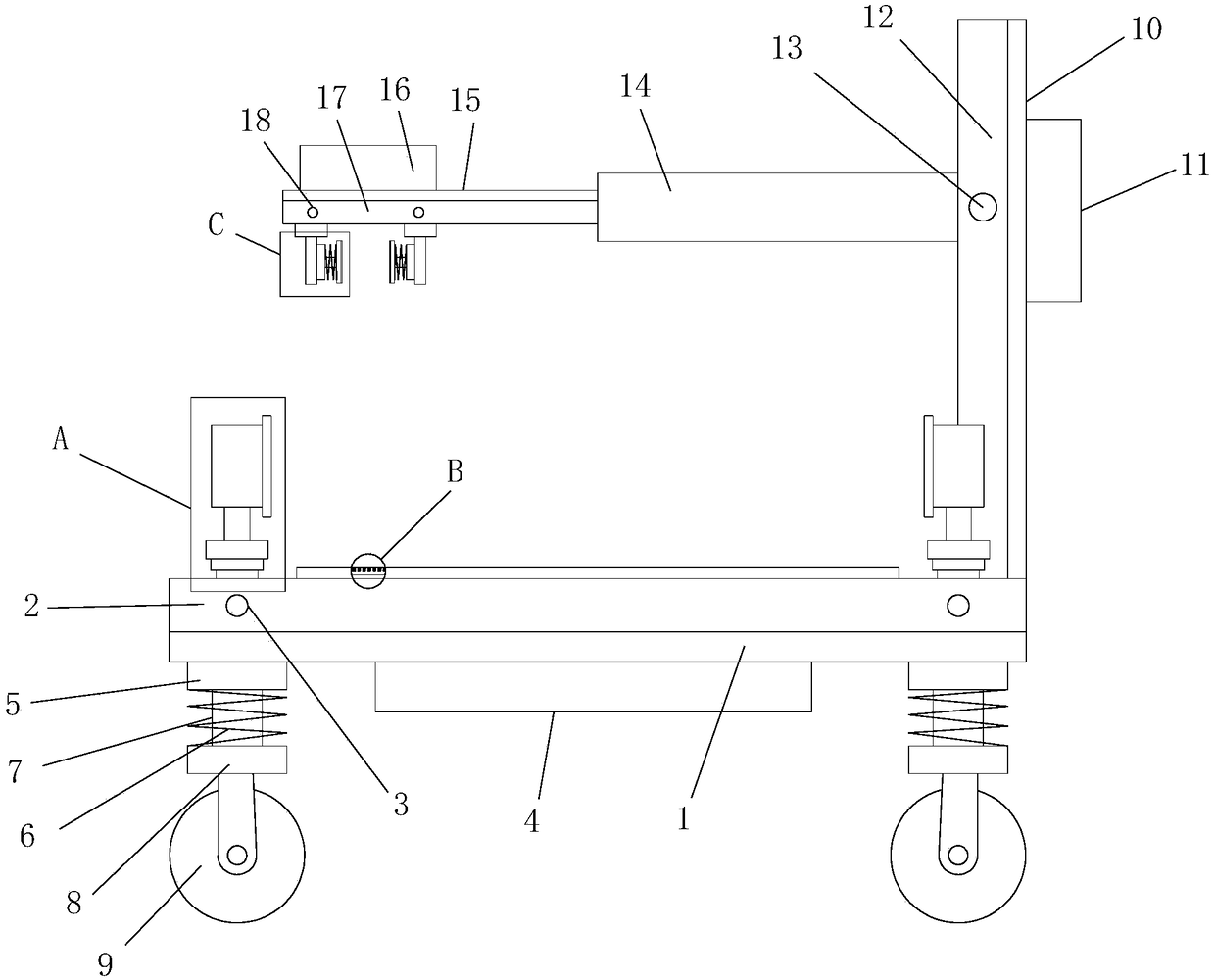

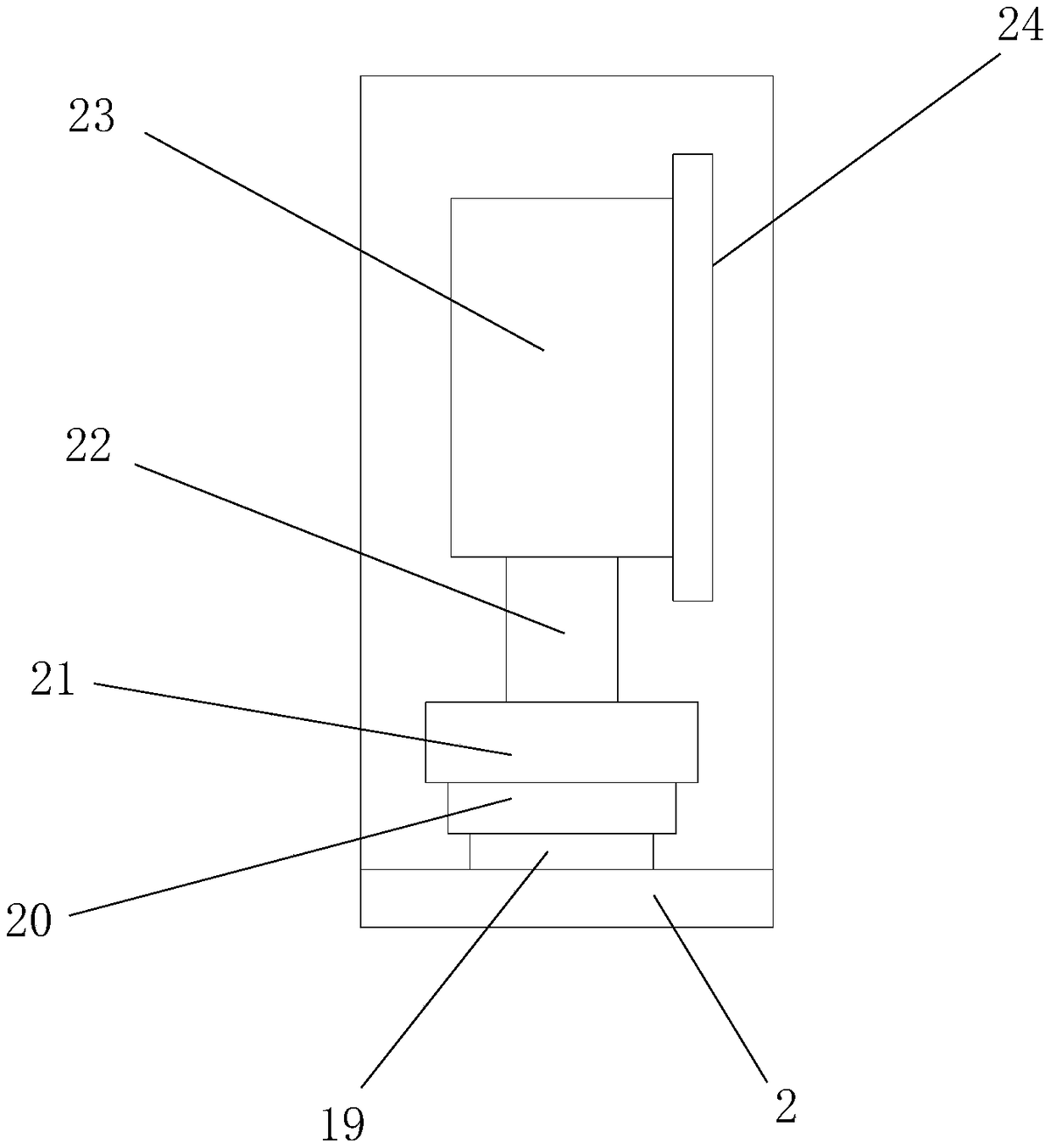

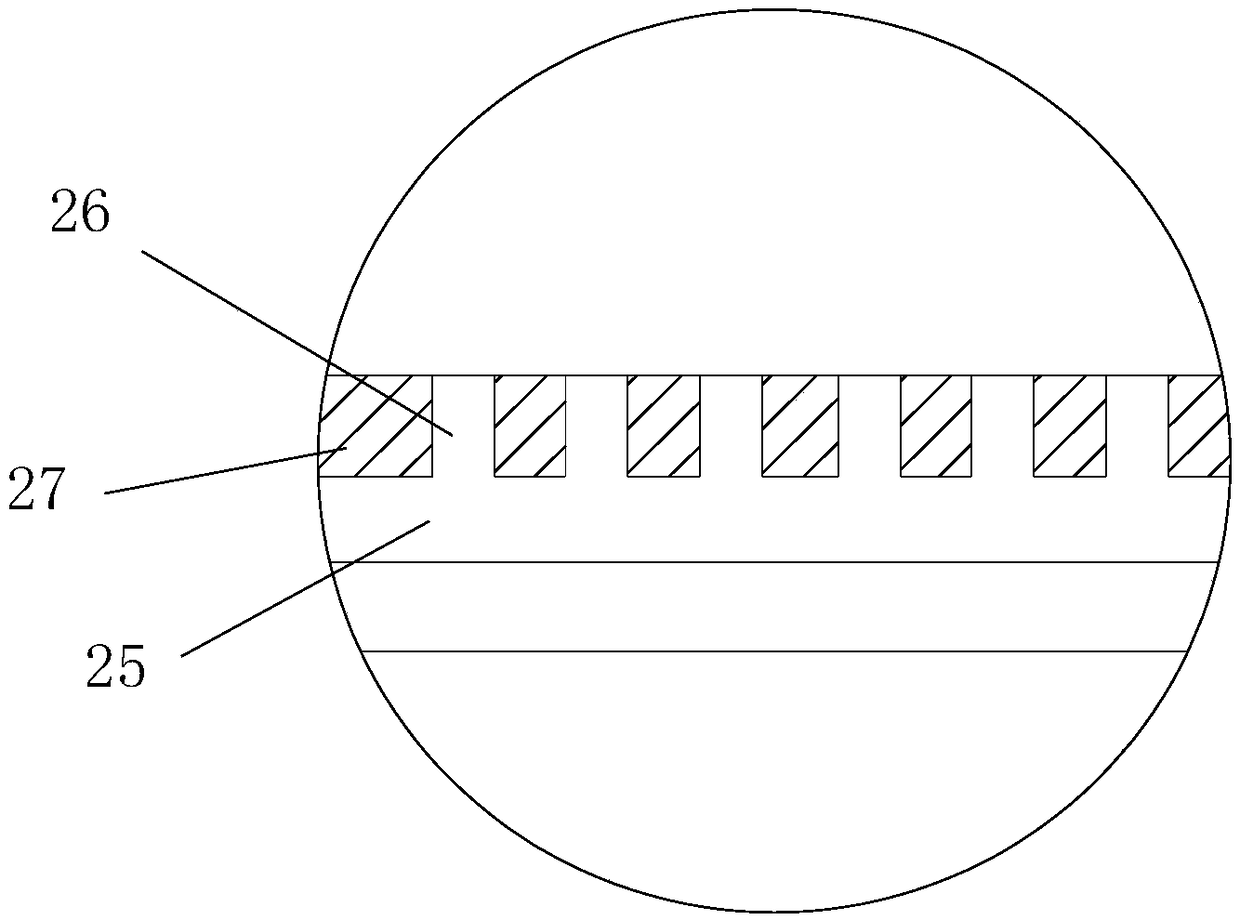

[0031] Such as Figure 1-6As shown, the present invention provides a solar cell crystalline silicon insert device, including a base 1 and a first limit seat 27 arranged on the upper end of the base 1, the base 1 is provided with a first chute 2, and the first chute 2 is symmetrical to the other. The center line is provided with a pair of first pulleys 3, the first slide plate 19 is installed on the first pulley 3, the end of the first slide plate 19 away from the first pulley 3 is equipped with a first mounting plate 20, the first mounting plate 20 is far away from the first A third piston 21 is installed on one end of the slide plate 19, a third piston shaft 22 is installed on the end of the third piston 21 away from the first mounting plate 20, and a first elastic plate is installed on the end of the third piston shaft 22 away from the third piston 21. Seat 23, a first elastic plate 24 is installed on one side of the first elastic plate mounting seat 23, the base 1 upper end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com